The throttle position sensor is probably one of the easiest components to test on your 1996 through 1999 3.8L V6 Ford Windstar.

This is basically due to the fact that you don't need any expensive diagnostic equipment to do it (a simple multimeter will do).

In this tutorial I'll explain, in a step-by-step manner, how to test the TPS to find out if it's defective or not.

NOTE: If you need to test the 1995 3.8L V6 Ford Windstar TPS, see this tutorial: How To Test The TPS (1994-1995 3.8L Taurus).

Contents of this tutorial:

ES ![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor TPS (1996-1999 3.8L Windstar) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor TPS (1996-1999 3.8L Windstar) (at: autotecnico-online.com).

Symptoms Of A Defective TPS

As you're probably already aware, the throttle plate (in the throttle body), is component that regulates the amount of air that enters your Ford Windstar's 3.8L engine.

To be a bit more specific: when you step on or off the accelerator pedal, the throttle plate opens or closes, this then has the effect of accelerating or decelerating the engine.

It's the job of the throttle position sensor (TPS) to inform your Ford Windstar's fuel injection computer the throttle plate angle. Since this TP sensor plays such an important part in the fuel injection system, when this bad boy fails, engine performance suffers. And when this happens you'll see one or more of the following symptoms:

- The check engine light (CEL) lit by one or more of the following trouble codes stored in the computer's memory.

- P0121: Throttle Position (TP) Sensor Range Performance.

- P0122: Throttle Position (TP) Sensor Low Input.

- P0123: Throttle Position (TP) Sensor High Input.

- Bad gas mileage.

- Lack of power when you accelerate the vehicle down the road.

- The engine hesitates when you accelerate the engine under load.

Where To Buy The TPS And Save

The following links will help to comparison shop for the 1996-1999 3.8L V6 Ford Windstar TPS:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Not sure if the above TPS is the correct one for your Ford Windstar? No worries, once you get to the site, they'll ask you for your vehicle's specific information and check that that fits. If it doesn't, they'll find you the right one.

TEST 1: Testing The TP Signal With A Multimeter

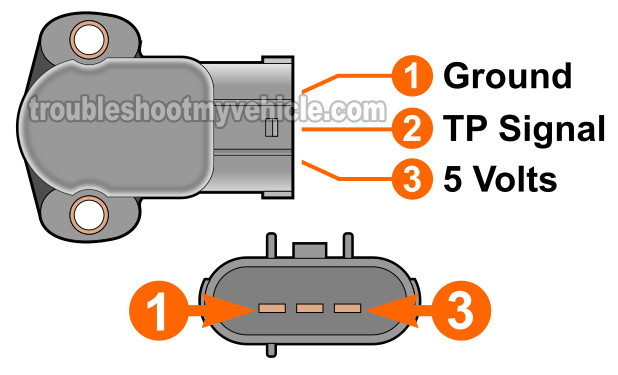

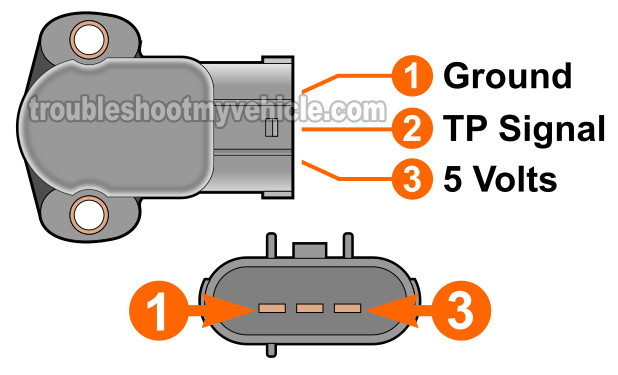

In this section we're gonna' connect a multimeter to the grey with white stripe (GRY/WHT) wire of the TP sensor electrical connector.

This will allow us to read the voltage signal that the TPS produces while we manually open and close the throttle plate.

If the TP sensor is defective (or if there's a problem in its wiring), you'll generally see that the TP signal voltage will stay stuck at a certain value irregardless of the throttle plate angle.

Now to be a bit more specific, what you should see when the throttle plate is closed is around 0.4 - 0.7 Volts DC.

When the throttle plate is at its wide open position, you should see a voltage reading of about 4.4 to 4.7 Volts DC.

NOTE: To be able to perform the TP signal voltage test, the TPS has to remain connected to its electrical connector. For this reason you'll need to use a back probe or a wire piercing probe to access the signal inside the wire. You can see an example of a wire piercing probe here: Wire Piercing Probe (at: easyautodiagnostics.com).

These are the test steps:

- 1

Place your multimeter in Volts DC mode and connect the red test lead to the GRY/WHT wire of the TP sensor harness connector.

The GRY/WHT wire connects to the TPS terminal identified with the #2 in the illustration above. - 2

Ground the black multimeter test lead directly on the battery negative (-) post.

- 3

Turn the key on but don't crank or start the engine. This will power up the TPS.

- 4

Manually rotate the throttle.

You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 5

The multimeter should show an increasing voltage as you (or your helper) open up the throttle.

You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 6

The multimeter should show a decreasing voltage as you begin to close the throttle.

- 7

Using a screwdriver's handle, gently tap the TP sensor as you open and close the throttle and observer the multimeter.

The purpose (of tapping the TP sensor with the screwdriver's handle) is to see if the TP sensor shows gap's in the voltage signal. Why? Because a good TP sensor will show a continuous increasing or decreasing voltage signal even while getting tapped by the screw-driver's handle.

Let's take a look at your test results:

CASE 1: The TP signal voltage increased/decreased as you opened/closed the throttle plate. This is the correct test result and lets you know that the TPS is working correctly. The TPS itself is not the cause behind the problem on your 3.8L Ford Windstar.

CASE 2: The TP signal voltage had blanks or skips as you opened/closed the throttle plate. This test result lets you know that the throttle position sensor is defective.

CASE 3: The TPS voltage signal stayed stuck at one value when you opened/closed the throttle plate. This test result generally tells you that the TP sensor is defective.

To make sure that it is defective, the next step is to make sure the TPS has power and Ground. For this test go to: TEST 2: Making Sure The TPS Is Getting 5 Volts And Ground.