In this tutorial, I'm going to explain how you can easily check the profile ignition pickup (PIP) sensor with a multimeter or an LED light on the 1990-1995 3.0L V6 Ford Taurus or Mercury Sable.

As you probably already know, the PIP sensor (located in the distributor) is the de facto crankshaft position sensor the ignition control module (ICM) and powertrain control module (PCM) use to know the exact piston position to start ignition spark and fuel injection.

All of the test steps are laid out in a clear, step-by-step manner so you can quickly figure out —based on your results— whether the PIP sensor is fried and needs to be replaced, or the issue lies somewhere else.

Contents of this tutorial:

- Basic Operating Theory Of The PIP Sensor.

- What Tools Do I Need To Test The PIP Sensor?

- TEST 1: Making Sure The PIP Sensor Is Getting Power.

- TEST 2: Making Sure The PIP Sensor Is Getting Ground.

- TEST 3: Testing The PIP Signal With A Multimeter.

- TEST 4: Testing The PIP SIG And PIP OUT Circuit.

- Testing The PIP Signal With An LED Light (Optional).

- More 3.0L V6 Ford Taurus Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 (OHV) Ford Taurus: 1990, 1991, 1992, 1993, 1994, 1995.

- 3.0L V6 (OHV) Mercury Sable: 1990, 1991, 1992, 1993, 1994, 1995.

IGNITION COIL AND IGNITION MODULE TESTS:

- Ignition Coil And Basic Ignition System Tests (1990-1995 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Ignition Control Module (1990-1995 3.0L V6 Ford Taurus, Mercury Sable).

IGN SYSTEM WIRING DIAGRAMS:

- Ignition System Wiring Diagram (1990 3.0L V6 Ford Taurus, Mercury Sable).

- Ignition System Wiring Diagram (1991 3.0L V6 Ford Taurus, Mercury Sable).

- Ignition System Wiring Diagram (1992-1995 3.0L V6 Ford Taurus, Mercury Sable).

ENGINE NO-START DIAGNOSTICS:

Basic Operating Theory Of The PIP Sensor

The profile ignition pickup (PIP) sensor is a Hall-effect type sensor that needs 12 Volts and Ground to produce its ON/OFF DC voltage signal.

As mentioned at the beginning of the tutorial, the PIP signal supplies piston-position and RPM information to both the ignition control module (ICM) and the PCM.

Here's some basic info that'll help you diagnose the PIP sensor:

- The PIP sensor needs 12 Volts, and it gets them directly from the ignition control module.

- The PIP sensor gets chassis Ground directly from the distributor assembly.

- As the engine cranks or runs, the distributor shaft rotates a shutter wheel with vanes through the PIP sensor assembly. As each vane passes the sensor, the PIP signal switches between near-zero Volts and near-battery voltage.

- The PIP signal is first sent to the ICM, which then channels it to the PCM via the PIP OUT circuit.

When diagnosing an engine no-start issue —or any performance problem that may be related to the PIP sensor— it's important to know the following:

- The ignition control module will only activate the ignition coil (to spark away) if it's receiving a PIP signal.

- If spark is present —as verified with a spark tester— then we can conclude that the PIP sensor is generating a valid signal that the ICM and PCM can use, and that the cause of the engine no-start is due to some other issue.

What Tools Do I Need To Test The PIP Sensor?

To test the ignition system, you don't need any expensive diagnostic equipment, but you'll need a few basic tools, and these are:

- 12V automotive test light: A regular 12V incandescent test light will help us check the ignition coil's activation signal in TEST 2. If you don't have one, this is the one I recommend —you can see it here: Lisle 28400 Heavy Duty 12 Volt Test Light (Amazon affiliate link).

- Multimeter: The multimeter will help us make sure the ignition coil's receiving battery power in TEST 4. If you don't have one, or if you're looking to upgrade, this is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Making Sure The PIP Sensor Is Getting Power

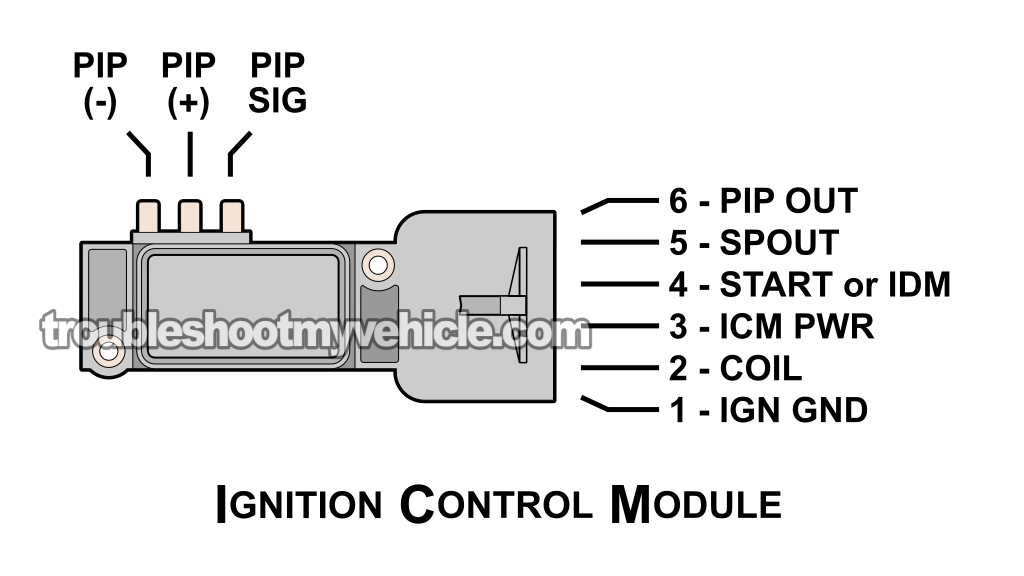

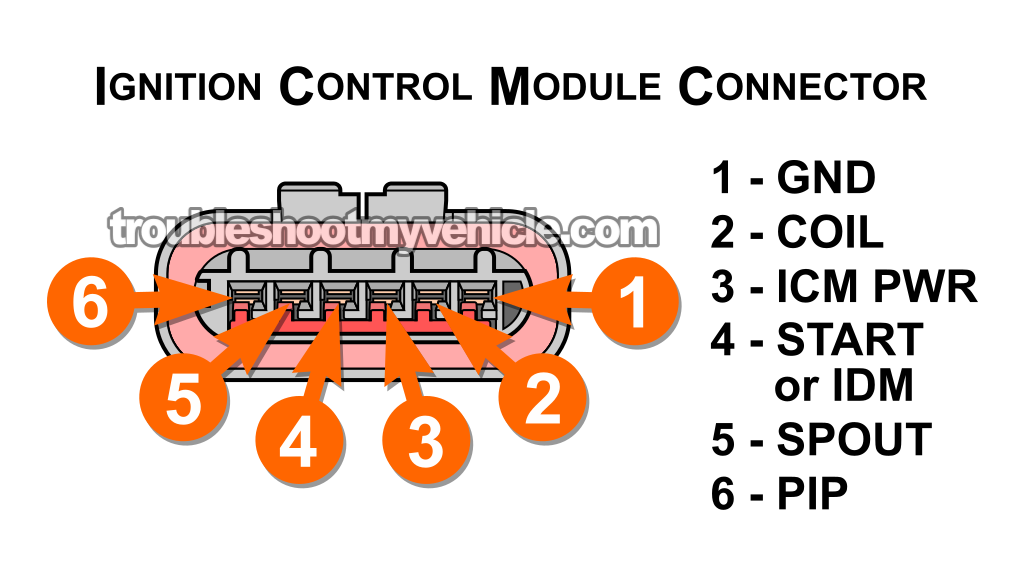

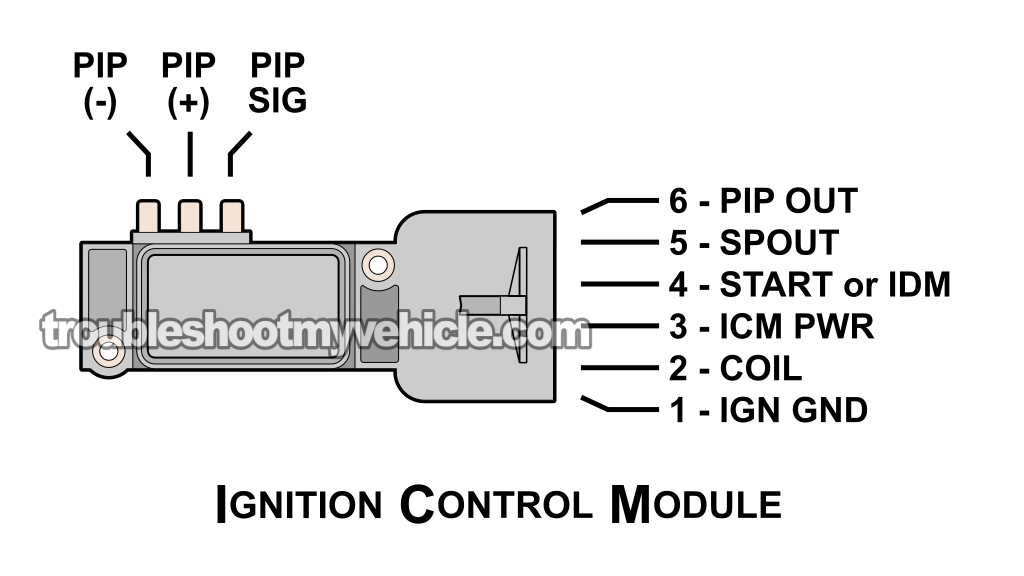

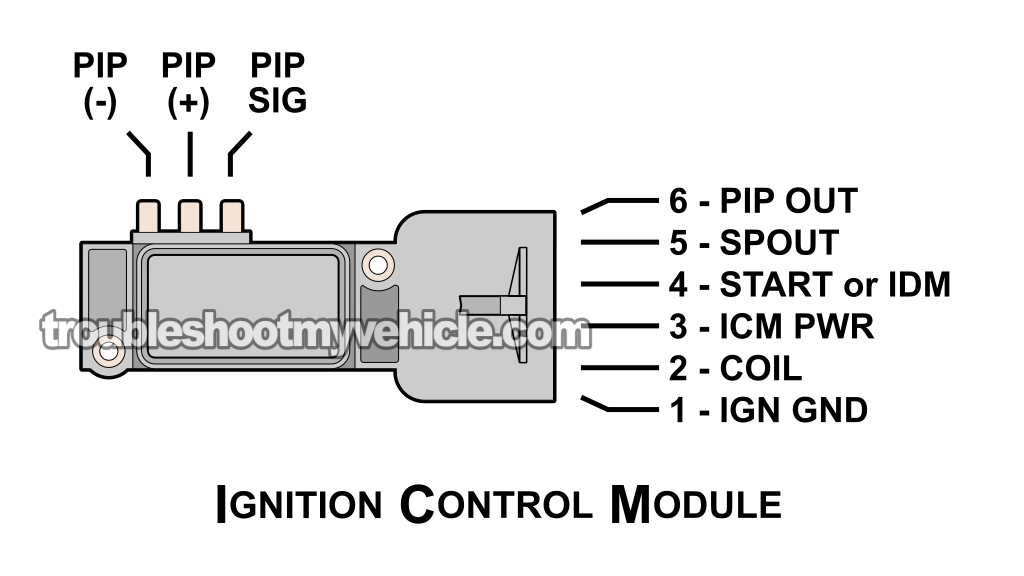

The ignition control module (ICM) is the component that supplies power to the PIP sensor. That power is first delivered to the module through the red with light green stripe (RED/LT GRN) wire of the module's 6-wire connector and then shared with the PIP sensor.

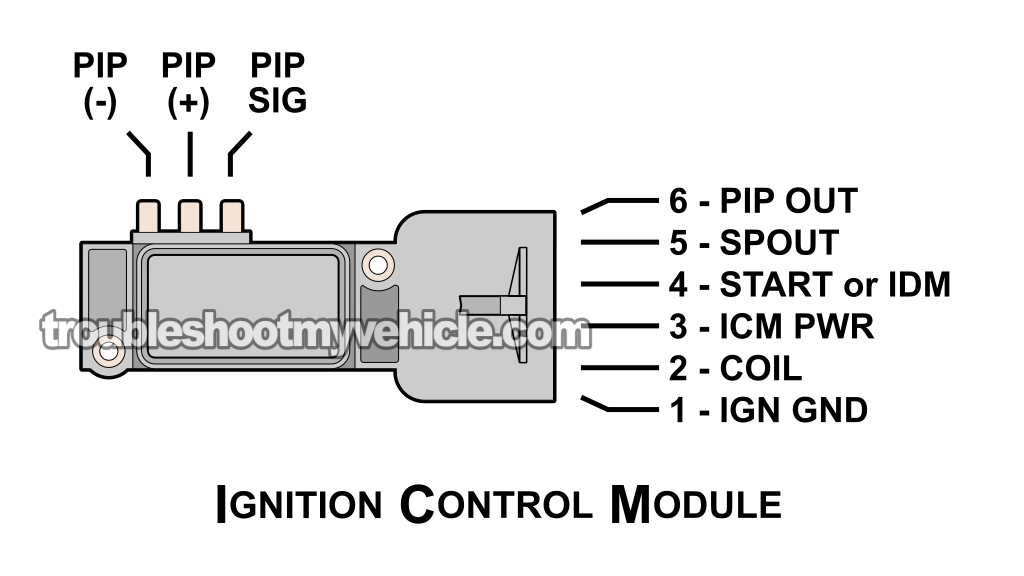

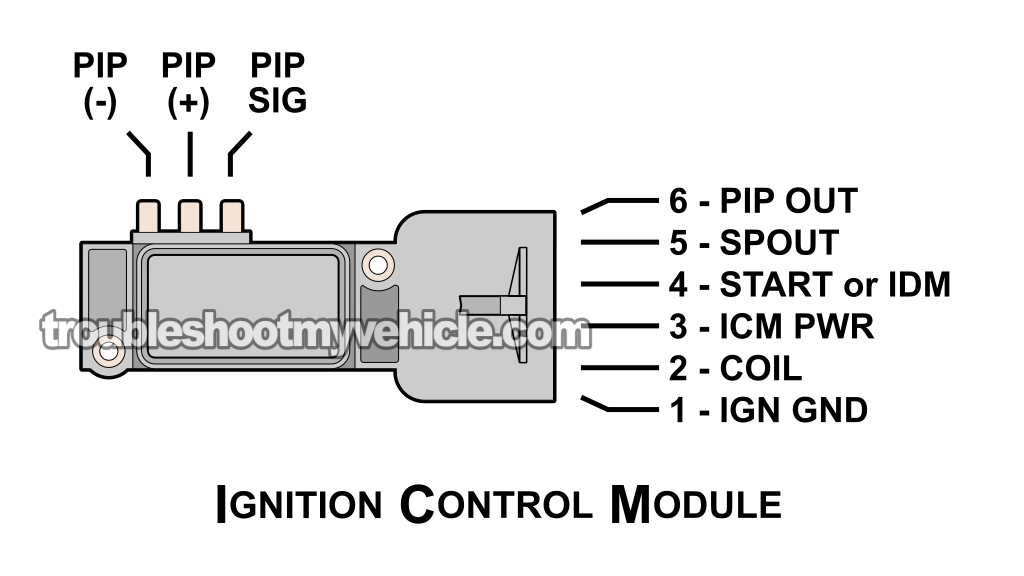

So our first order of business is to check that the ICM is actually getting battery voltage at female terminal 3 —which is the terminal that connects to the RED/LT GRN wire of its connector (see the ICM connector pinout illustration above).

This battery voltage at terminal 3 is only available when the ignition key is in either the RUN or START position. For our test, we're going to check for battery voltage with the key in the RUN position but with the engine OFF.

Alright, here's what we need to do:

- 1

Disconnect the ignition module from its 6-wire connector.

- 2

Place your multimeter Volts DC mode.

- 3

Connect the black multimeter test lead to the battery negative (-) post.

- 4

Turn the key to the ON position but don't start the engine.

- 5

With the red multimeter test lead, probe female terminal 3 of the connector.

NOTE: Double-check that terminal 3 corresponds to the RED/LT GRN wire. - 6

Your multimeter should read 10 to 12 Volts DC.

Let's interpret your test result:

CASE 1: Terminal 3 has battery voltage present. So far so good —this is the correct and expected test result.

Now, I don't want to get ahead of myself, but this only confirms that the ignition control module is getting power. In another test, we're going to make sure the ICM is actually channeling this voltage to the PIP sensor.

For now, our next step is to make sure the PIP sensor (via the distributor) has a solid connection to chassis Ground. For this test, head over to: TEST 2: Making Sure The PIP Sensor Is Getting Ground.

CASE 2: Terminal 3 DOES NOT have battery voltage present. If the ignition module isn't getting power, neither is the PIP sensor, since the ICM is the one that channels this voltage from terminal 3 to the PIP sensor.

Your next step is to find out why battery voltage is missing on the RED/LT GRN wire and solve the issue. Once power is restored to this circuit, the ignition system should function again and the engine should start.

TEST 2: Making Sure The PIP Sensor Is Getting Ground

The PIP sensor, along with the ignition control module, get Ground from the same circuit —and this Ground is a chassis Ground that is supplied by the distributor itself.

To check that the PIP sensor has a solid path to chassis Ground, we're gonna make sure that there isn't any voltage drop between the IGN GND circuit wire of the ICM's 6-wire connector and the battery negative (-) terminal.

Depending on the year of your specific Taurus or Sable this IGN GND wire will be:

- 1990: Black with orange stripe (BLK/ORG).

- 1991-1995: Orange wit red stripe (ORG/RED).

We can expect one of two things from this battery voltage test:

- The multimeter reports battery voltage: This lets us know the IGN GND circuit is OK.

- The multimeter reports a voltage way under battery voltage: This confirms the IGN GND circuit has a problem.

NOTE: This test is done with the ignition module connected to its 6-wire connector. You'll need to pierce the IGN GND wire with a wire-piercing probe to perform this test. If you don't have a wire-piercing probe, this is the one that I use and recommend: Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link).

OK, let's get to it:

- 1

Disconnect the PCM from its 60-pin connector.

This is an important step as it'll isolate the circuit to just the ICM and PIP sensor.

NOTE: Before you disconnect the PCM from its connector, disconnect the battery from its negative (-) cable. Once the PCM is disconnected, reconnect the battery back to its negative (-) cable. - 2

Set your multimeter to Volts DC mode.

- 3

Measure the battery voltage directly across the battery posts with your multimeter.

This will be your baseline voltage reading, which we'll use for comparison in the following test steps. - 4

Connect the red multimeter test lead to the center of the battery positive (+) post.

- 5

With the black multimeter test lead, probe IGN GND wire of the ICM connector. Make your connection as far away from the plastic connector as possible.

The wire will a BLK/ORG (1990) or an ORG/RED (1991-1995) wire.

NOTE: The ignition module must remain connected to its 6-wire connector to perform this test. - 6

You should see a voltage reading no less than 0.5 Volts of battery voltage.

NOTE: From my experience, when there's an issue with the IGN GND circuit not having a good path to chassis Ground —causing a PIP sensor performance problem— you'll typically see a multimeter reading of 10 Volts or less instead of full battery voltage.

Now, let's interpret your test result:

CASE 1: The multimeter reported battery voltage. This lets us know the PIP sensor has a good connection to chassis Ground.

Next up, we're going to check the PIP signal. Now, there are two ways to check the PIP signal: one is with an LED light, and the other is with a multimeter. We're going to move on to the multimeter voltage test because it's the most accurate way to check the PIP signal's ON/OFF voltage. Go to: TEST 3: Testing The PIP Signal With A Multimeter.

NOTE: At the end of the tutorial, I'll still include the LED light test, but the best way to go is to check the signal's actual voltage output.

CASE 2: The multimeter reported a value much lower than battery voltage. This test result lets us know there's a problem with the IGN GND circuit and that a voltage drop is preventing a clean, solid path to chassis Ground.

This is usually caused by one of two things:

- The battery cable that connects the battery negative (-) post to the engine block is loose, or the terminals on either end of the cable are heavily corroded.

- The round metal terminals of the PIP sensor wiring (the ones that provide the chassis Ground connection inside the distributor) are loose or corroded.

You can further troubleshoot this issue by first checking the battery negative cable terminals —both the end that connects to the battery negative (-) post and the terminal that connects to the engine block and chassis of your Ford Taurus or Mercury Sable. Both connection points must be clean and corrosion-free— no rust, no oxidation. Once you've inspected and cleaned these terminals, repeat the test.

If the voltage drop is still present and you're still not seeing full battery voltage in the IGN GND circuit, then your next step is to remove the distributor cap and inspect the PIP sensor's Grounding point inside the distributor. Make sure the two Grounding screws are tight and that the round metal terminals are clean and free of corrosion.

TEST 3: Testing The PIP Signal With A Multimeter

Up to this point, you've checked the ICM PWR circuit and the IGN GND circuit, and so far you haven't run into any issues with either one.

For our next test, we're going to check the PIP signal with a multimeter and make sure that the ON/OFF voltage signal the PIP sensor is generating —if it's generating one— is within the correct parameters.

Specifically, this is what we're looking for:

- ON: PIP signal voltage is above 8 Volts DC.

- OFF: PIP signal voltage is below 2 Volts DC.

Here's some important info you need to keep in mind about this test:

Checking the PIP signal with a multimeter requires that you turn the crankshaft pulley by hand using a ½-inch ratchet and the appropriate socket on the crankshaft pulley bolt. And to access the crank pulley, you'll need to raise the front passenger side of the vehicle, remove the tire, and remove the splash shield. I know it's a bit time-consuming, but this is the most accurate way to test the PIP signal with a multimeter since you cannot use the starter motor for this method.

The PIP signal test involves tapping into the PIP OUT wire that connects to terminal 6 of the ICM's 6-wire connector. Depending on the specific year of your Ford Taurus or Mercury Sable, this wire will be one of the following colors:

- 1990-1991: Dark Blue (DK BLU).

- 1992-1995: Gray with orange stripe (GRY/ORG).

NOTE: To perform this test, the ICM must remain connected to its 6-wire connector. You can either back-probe the terminal or use a wire-piercing probe on the PIP OUT signal wire. I personally avoid back-probing weather-sealed connectors, so my go-to method is using a wire-piercing probe. If you don't have one, this is the tool I use and recommend: Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link).

IMPORTANT: You'll need to raise the front right side of your Ford Taurus or Mercury Sable, remove the tire and the splash shield, and access the crankshaft pulley. Be sure to place your vehicle securely on a jack stand —never trust the jack alone to keep the vehicle raised.

This is what you need to do:

- 1

Raise the front right side of your vehicle and place it on a jack stand.

IMPORTANT: NEVER trust the jack alone to keep the vehicle raised. ALWAYS use jack stands. - 2

Remove the front right tire and the water splash shield that is covering the crankshaft pulley.

- 3

Disconnect the ignition coil from its electrical connector.

NOTE: This is an important safety precaution —do not continue to the next step without doing this first. - 4

Set your multimeter to Volts DC mode.

- 5

Connect the black multimeter test lead to the battery negative (-) terminal.

- 6

Connect the red multimeter test lead to the PIP OUT signal wire, using the appropriate tool.

The PIP signal wire connects to terminal 6 and will be either a DK BLU wire (1990-1991) or a GRY/ORG wire (1992-1995).

NOTE: The ignition module must remain connected to its 6-wire connector. - 7

Turn the ignition key to the ON position, but don't start or crank the engine.

- 8

Slowly rotate the crankshaft pulley by hand using a 1/2-inch ratchet and the appropriate socket.

NOTE: Rotate the pulley at least two full revolutions to ensure all of the tone wheel slots pass by the Hall effect sensor. - 9

Watch your multimeter for voltage changes. Voltage should toggle between ON and OFF voltage states as you turn the crankshaft pulley.

ON: Voltage above 8 Volts DC.

OFF: Voltage below 2 Volts DC.

OK, let's interpret your test results.

CASE 1: The PIP sensor is generating its ON/OFF voltage, and the ON voltage is above 8 Volts. This is exactly what we wanted to see, and it confirms that the PIP sensor is functioning correctly.

If you're troubleshooting a no-start due to no spark, we can now rule out the PIP sensor as the cause. If you haven't already done so, your next diagnostic steps should be checking the ignition coil and the ignition control module. I've written step-by-step tutorials that'll walk you through both tests:

- Ignition Coil And Basic Ignition System Tests (1990-1995 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Ignition Control Module (1990-1995 3.0L V6 Ford Taurus, Mercury Sable).

CASE 2: The PIP sensor is generating its ON/OFF voltage, but the ON voltage is below 8 Volts. This test result tells you that even though the PIP sensor is producing a signal, it's failing, because its ON-voltage peak must be above 8 Volts. On a healthy PIP sensor, the ON voltage is usually right around battery voltage (close to 12 Volts).

In this situation, there's a good chance the PIP signal is enough to get the ICM to get the ignition coil to spark and get the engine started —but you may notice intermittent or strange engine performance issues caused by the weak PIP signal reaching the PCM.

CASE 3: The PIP sensor isn't generating its ON/OFF voltage signal. Double-check that you're testing the correct wire of the ICM's connector and repeat the test.

If the ON/OFF voltage pulses are still not present in the PIP OUT wire, then there's a good chance the PIP sensor itself is fried. But to be absolutely sure, we've got to do one more test. Go to: TEST 4: Testing The PIP SIG And PIP OUT Circuit.

TEST 4: Testing The PIP SIG And PIP OUT Circuit

When the profile ignition pickup (PIP) sensor produces its signal, that signal is first sent directly to the ignition control module. The ignition module uses this signal to activate the ignition coil, but it also channels the signal to the PCM through terminal 6 —which is the PIP OUT circuit.

Since in TEST 3 you did not see an ON/OFF voltage signal (of the ON voltage was under 8 Volts DC), our next step is to make sure that the PIP SIG → PIP OUT circuit inside the ignition module has continuity.

Specifically, this circuit must have a resistance of less than 200 Ohms. Any resistance value that is excessively high —like readings in the thousands of Ohms or an open-circuit— confirms that the module is not allowing the PIP signal to exit on the PIP OUT wire.

IMPORTANT: To test the resistance of the PIP SIG → PIP OUT circuit, the ignition module must be removed from the distributor. When reinstalling the ignition module afterward (whether it's the same one or a new one), it is absolutely critical that you apply thermal paste to the mating surface between the module and the distributor. I want to point out that thermal paste is NOT the same as dielectric grease. These are two completely different substances. If you use dielectric grease instead of thermal paste, the ignition module will overheat and fry within a short period of engine operation.

OK, these are the test steps:

- 1

Disconnect the ignition module from its 6-wire connector.

- 2

Remove the ignition control module from the distributor.

You'll need a 5.5mm or 7/16" socket to remove the two small bolts securing the module to the distributor.

NOTE: You may need to slightly loosen the distributor and rotate it to access the bolts securing the module. If you do, make sure to create alignment marks on both the distributor and the engine before moving it. This will ensure that once you're done, you can reinstall and tighten the distributor back into its exact original position. - 3

Set your multimeter to Ohms mode.

- 4

Check the resistance between the PIP SIG pin and the PIP OUT pin.

NOTE: These "pins" are the male spade terminals on the ICM itself —see the pinout ID illustration of the ignition module above. - 5

Your multimeter should register a resistance under 200 Ohms.

Let's see what your result means:

CASE 1: The resistance of the circuit is under 200 Ohms. This confirms that the circuit inside the ignition module is OK.

We can confidently say that the PIP sensor is toast and behind the engine no-start problem only if you have checked and confirmed all of the following:

- None of the six spark plug wires are sparking.

- The ignition coil is not sparking when tested directly at its tower.

- The ignition control module (ICM) is getting battery voltage (TEST 1).

- The ICM is not activating the ignition coil to spark (TEST 2).

- You have confirmed that the PIP sensor is generating its ON/OFF voltage pulse and that the ON voltage is above 8 Volts DC (TEST 3).

- In this test section, you've verified that the PIP SIG → PIP OUT circuit inside the ignition module has less than 200 Ohms of resistance.

CASE 2: The resistance is not within specification. This test result confirms that there is a problem with the PIP SIG → PIP OUT circuit inside the ignition control module. The ignition module is bad and needs to be replaced.

NOTE: In some very rare cases, although the PIP SIG → PIP OUT circuit isn't within specification —indicating that the ignition module is fried— the PIP sensor in the distributor can also be malfunctioning. You'll need to replace the ignition control module and crank the engine to get it started. If the engine still doesn't start due to a lack of spark, then the PIP sensor is now the prime suspect.

If this happens in your particular situation —where you've installed a brand-new ignition module and you still don't get spark— then repeat the PIP signal multimeter voltage test described in TEST 3. Since the new ignition module will have the PIP SIG → PIP OUT circuit reading under 200 Ohms, you should now be able to confirm if the PIP sensor isn't creating a viable PIP signal, since it can be properly measured as it's sent out through the PIP OUT wire.

Testing The PIP Signal With An LED Light (Optional)

I've been using an LED light to check crankshaft position (CKP) signals for most of my automotive repair career. The benefit of using an LED light is that it lets me crank the engine with the starter motor.

Although it's not the most accurate way to check the signal from the profiled ignition pickup (PIP) sensor —which is the de facto CKP sensor on your Ford Taurus or Mercury Sable— it's still a test worth knowing and doing.

So I've included it in this test section in case you want to try it out. As you know, the PIP sensor produces an ON/OFF voltage pulse. We can use the LED light to visually see those ON/OFF voltage pulses causing the LED to flash ON and OFF, if the PIP sensor is actually generating its signal.

So, in a nutshell:

- LED light flashes ON and OFF. This confirms the PIP signal is present.

- LED light does not flash ON and OFF. Now we know the PIP signal is not being generated.

Before we get started, keep in mind that depending on the specific year of your Ford Taurus or Mercury Sable, the PIP signal wire at the ICM's 6-wire connector will be one of the following colors:

- 1990–1991: Dark blue (DK BLU).

- 1992–1995: Gray with orange stripe (GRY/ORG).

If you don't have an automotive 12V LED light, you can buy it here: Oznium Flush Mount 12V LED Light (Amazon affiliate link).

No matter the wire color, the PIP signal wire connects to terminal 6 of the ICM's 6-wire connector (see the illustration of the ICM above to identify the correct terminal).

CAUTION: You'll be working around a cranking engine. Keep your hands, tools, loose clothing, and test leads clear of moving engine parts such as belts and pulleys. Secure any long hair and avoid leaning over the engine while performing the test. Always stay alert and aware of your surroundings when working near moving components.

This is what you need to do:

- 1

Disconnect the ignition coil from its electrical connector.

NOTE: This is an important safety precaution —do not continue to the next step without doing this first. - 2

Disconnect the ICM from its 6-wire connector.

- 3

Connect the red wire of the LED light to the battery positive (+) terminal.

NOTE: You'll need to use a jumper wire to have the red lead of the LED reach the battery terminal. - 4

Connect the black wire of the LED to the PIP signal wire, using the appropriate tool.

The PIP signal wire connects to terminal 6 and will be either a DK BLU wire (1990-1991) or a GRY/ORG wire (1992-1995). - 5

When all is set up, crank the engine.

- 6

The LED light should flash ON and OFF as the engine cranks if the PIP signal is being generated and sent to the ICM.

OK, let's interpret your test results:

CASE 1: The LED light flashed ON and OFF as the engine was cranking. Since the LED light is flashing ON and OFF, you can conclude that the PIP sensor is generating a signal.

If you're troubleshooting an engine no-start problem due to a lack of spark at all six spark plug wires, then this test result rules out the PIP sensor itself as the cause. If you haven't already checked the ignition coil and the ignition control module, those are your next diagnostic steps. I've written step-by-step tutorials on how to check these two components, and you can find them here:

- Ignition Coil And Basic Ignition System Tests (1990-1995 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Ignition Control Module (1990-1995 3.0L V6 Ford Taurus, Mercury Sable).

CASE 2: The LED light did not flash ON and OFF as you cranked the engine. First, check that the LED light itself is working by connecting it to the battery on your Ford Taurus or Mercury Sable. If the light does come on, then repeat the test one more time.

NOTE: The LED light is polarity-specific, so you'll need to connect the red lead to the battery (+) post and the black lead to the battery (–) post.

If the LED light still doesn't flash ON and OFF as you're cranking the engine, then this result lets you know the PIP sensor in the distributor isn't producing its signal and has kicked the bucket. It needs to be replaced —but only after you've checked and confirmed the following.

- In TEST 1, you confirmed the PIP sensor is getting battery voltage.

- In TEST 2, you confirmed it has a solid path to chassis Ground.

- And in this test section, you've confirmed it's not generating its ON/OFF voltage signal.

More 3.0L V6 Ford Taurus Diagnostic Tutorials

You can find a complete list of diagnostics tutorials for the 3.0L V6 Taurus and Mercury Sable in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The MAF Sensor (1991-1995 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (1990-1999 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The TPS With A Multimeter (1991-1995 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test For A Blown Head Gasket (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

If this info saved the day, buy me a beer!