There are some diagnostic tests that require that you check the continuity of a circuit between the PCM connector and the sensor connector.

These tests definitely come in handy when you're trying to see if an electrical issue in the wiring between the PCM and the component is causing the component to malfunction or simply not work.

But probing those delicate PCM terminals the wrong way can cause a pretty big headache if you used the wrong tool or method.

In this guide, I'm going to share some tips I've picked up over the decades working on cars —things you don't want to do, and more importantly, what you can do to safely probe the female terminals on your PCM connector.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Ford Taurus: 1990, 1991, 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007.

- 3.0L V6 Mercury Sable: 1990, 1991, 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005.

What I Don't Do (And Why)

The PCM on your 3.0L V6 Taurus or Sable is either an EEC-IV (1991–1995) with a 60-pin connector or an EEC-V (1996–2007) with a 104-pin connector. Both are located in the engine compartment, and both use a weather-sealed design built to withstand heat, vibration, and moisture.

When probing this connector, there are two things you need to keep in mind:

- Each wire passes through a small rubber seal where it enters the PCM connector. These seals are there to keep moisture away from the metal terminals inside.

- The round female terminals themselves are very small —and easy to deform if the wrong probe is forced in.

If a seal gets pierced or a terminal gets spread open, you've now created an opening for moisture and corrosion. Over time, this leads to poor contact, intermittent electrical problems, and drivability issues that are gonna be a nightmare to troubleshoot down the road.

Here's what I avoid doing when probing the PCM's connector:

-

I don't use standard multimeter test leads to probe the female terminals.

The metal probes on standard multimeter leads are way too thick to safely probe the female terminals of the connector. Forcing them in can permanently spread the terminal, causing intermittent false connections or even a "dead" circuit that'll lead to engine performance problems. Believe you me, that's something we definitely need to avoid.

-

I don't back-probe the connector.

Although back-probing the connector is the standard way to test these circuits, it comes with a hidden problem. Those tiny rubber seals the wires pass through —the ones that keep moisture out— usually get punctured by the back probe. That little hole becomes a permanent entry point for moisture. Over time, that moisture will cause the terminals to corrode. Add in the heat from the engine and the vibration from the road, and things only get worse.

So what's the safe way?

To safely test the PCM connector, you need to use precision automotive test probes. Their metal tips are much thinner than standard multimeter leads, so when you use them on the terminals, you don't have to worry about stretching or permanently opening up the female terminal.

Personally, I use a wire-piercing probe kit that lets me remove the needle probe from the housing and use it directly on PCM terminals:

- Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link).

Here are some other kits that'll also do the job:

- AUTOOL 68PCS Multimeter Test Leads Kit (Amazon affiliate link).

- LUTIFIX 68PCS Automotive Circuit Test Leads Kit (Amazon affiliate link).

Now, the downside to using precision probes is they're not always cheap. On top of that, you usually have to order them online and wait for them to show up. But compared to the nightmare of damaging the PCM connector and having to replace the entire wiring harness —because the connector is now causing intermittent false connections and weird engine performance issues— those probes are worth every penny.

The Safe, Low-Cost Method I Use

I definitely recommend using precision probes with thin tips to probe the PCM connector terminals. But if, for whatever reason, you can't get your hands on any, here's a simple and reliable method I've used over the years to safely probe the front of the female terminals on the PCM connector.

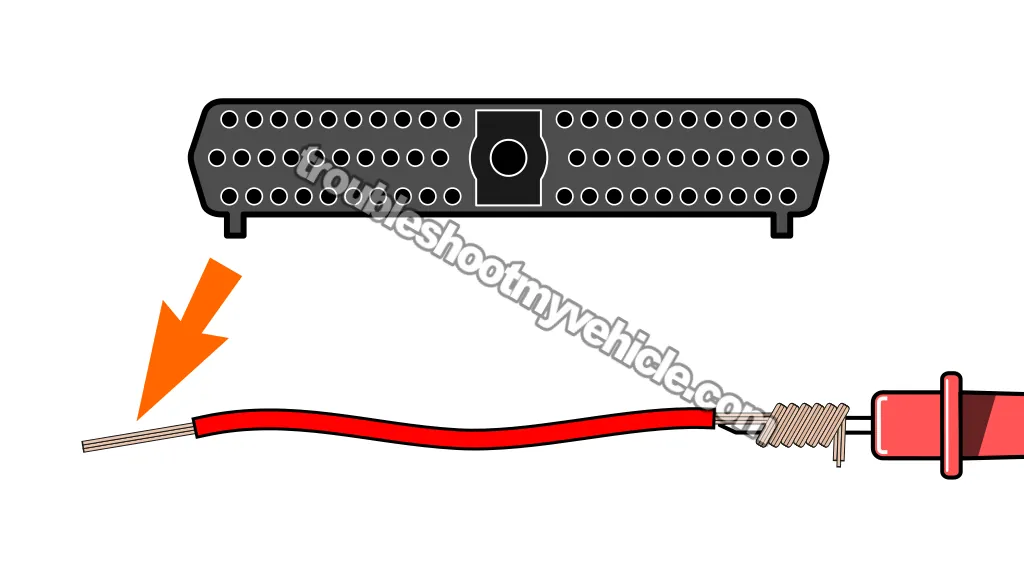

In a nutshell, this method uses a piece of wire as the probe, inserted into the round female terminal of the connector. Here's how it works:

- Grab a small piece of scrap wire, about 3 to 4 inches long. I usually pull one from an old engine wiring harness, but any automotive-grade wire you've got lying around will do just fine.

- Strip about ½ to 1 inch of insulation off both ends of the wire.

- On one end, wrap the bare copper strands tightly around the metal tip of your multimeter lead. You want a good, solid connection here.

- Wrap a small strip of electrical tape around the test lead where the copper is wrapped.

- This keeps the connection tight and also insulates it, so the exposed wire doesn't accidentally touch metal and throw off your reading.

- On the other end, insert the bare copper into the PCM connector terminal (the same side the PCM plugs in —not the back).

- If the wire has too many strands to slide in cleanly, just trim a few off with wire cutters. You want it to go in with slight resistance, enough to make a good and solid contact.

This method gives you a clean, reliable connection to the PCM terminal with no risk of spreading or damaging it. When you're done testing, just pull the wire out and plug the connector back in like normal.

Always Disconnect The Battery Before Working On The PCM Connector

Any time you're disconnecting or reconnecting your Taurus or Sable's PCM connector, you need to first disconnect the battery negative (–) cable.

This isn't just good practice, it's essential. The PCM has sensitive internal circuits that can be fried in an instant if voltage is present while you're plugging or unplugging the connector. Even a small arc or static charge can cause an expensive failure you don't want to deal with.

So before you touch the PCM connector, pull the key out of the ignition, wait a minute or two, and disconnect the battery negative (–) terminal.

When you're done with your testing or repair, go ahead and reconnect the battery as your final step.

More 3.0L V6 Ford Taurus Diagnostic Tutorials

You can find a complete list of diagnostics tutorials for the 3.0L V6 Taurus and Mercury Sable in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The MAF Sensor (1991-1995 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test For A Blown Head Gasket (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Injectors (1991-1995 3.0L Ford Taurus).

- How To Do And Interpret An Engine Compression Test (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

If this info saved the day, buy me a beer!