In this tutorial, I'll explain how to test the resistance of the fuel injectors on the 1991, 1992, 1993, 1994, And 1995 3.0L V6 (OHV) Ford Taurus (Mercury Sable).

The fuel injector resistance test is pretty easy and it's done with a multimeter. Now what complicates things a bit is fact that three of the fuel injectors are located beneath the intake manifold plenum.

NOTE: This tutorial also applies to the following vehicles: 1991-1994 3.0L Ford Tempo, 1991-1992 3.0L Ford Probe, and 1991-1995 3.0L Mercury Sable.

Contents of this tutorial:

- Symptoms Of A Defective Fuel Injector.

- Where To Buy The Fuel Injector.

- Testing The Fuel Injector Resistance.

- Checking The Injector's Resistance Directly At Its Terminals.

- How To Find The Bad Or Clogged Fuel Injector.

- Precautions To Take When Removing The Intake Manifold Plenum.

- More 3.0L V6 Ford Taurus Diagnostic Tutorials.

ES ![]() You can find this tutorial in Spanish here: Cómo Probar Los Inyectores (1991-1995 3.0L Taurus) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar Los Inyectores (1991-1995 3.0L Taurus) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Ford Taurus: 1991, 1992, 1993, 1994, 1995.

- 3.0L V6 Mercury Sable: 1991, 1992, 1993, 1994, 1995.

FUEL INJECTOR CIRCUIT DIAGRAMS:

- Fuel Injector Circuit Wiring Diagram (1991 3.0L V6 Ford Taurus, Mercury Sable).

- Fuel Injector Circuit Wiring Diagram (1992 3.0L V6 Ford Taurus, Mercury Sable).

- Fuel Injector Circuit Wiring Diagram (1993-1995 3.0L V6 Ford Taurus, Mercury Sable).

FUEL INJECTOR SPRAY TEST:

Symptoms Of A Defective Fuel Injector

A bad fuel injector can cause several different symptoms. What you'll usually see is a rough idle condition or a misfire when the engine is idling or accelerated under load.

Here's a brief list of symptoms that you'll see when one or several fuel injectors fail on your 3.0L Ford Taurus (Mercury Sable):

- Rough idle.

- Lack of power when you accelerate your Ford on the road.

When fuel injectors fail, they usually fail for one of the following reasons:

- The internal coil winding (of the fuel injector) suffers a short-circuit or an open-circuit. When this happens, the fuel injector will stop injecting fuel completely.

- The fuel injector becomes clogged and does not atomize the fuel correctly or doesn't inject enough fuel.

- The fuel injector does not activate because it's not getting either power or activation signal from the fuel injection computer.

- The fuel injector comes on and stays on due to a short in the wiring for a defective fuel injection computer.

In this tutorial, we're going to focus on testing the internal coil winding of the fuel injectors to see if they are in a short-circuit or open-circuit state. Testing for a clogged fuel injector isn't hard and I'll offer you some suggestions in the next page.

Where To Buy The Fuel Injector

The fuel injectors on your Ford Taurus or Mercury Sable are not too expensive. You can save further by shopping online for them:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Not sure if the fuel injectors above fit your particular 3.0L Ford Taurus (Mercury Sable)? Don't worry, once you get to the site, they'll ask you for the specifics of your Ford and make sure they fit.

Testing The Fuel Injector Resistance

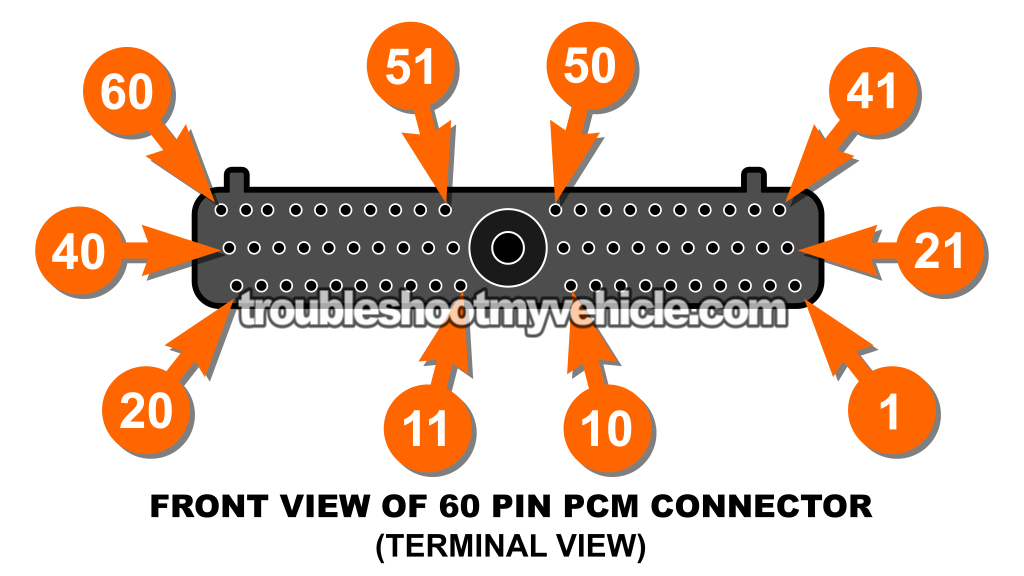

To start off our fuel injector diagnostic, we're going to check the resistance of the fuel injector circuit with a multimeter in Ohms mode from the PCM's 60-pin connector.

In other words, we're going to disconnect the 60-pin PCM connector from the PCM itself and check the resistance of the entire fuel injector circuit, which includes the injector and the wiring between the injector and the PCM —at the terminals I'm going to indicate to you in the test instructions.

What we're looking for —we're going to see one of two results:

- Good fuel injector circuit: The multimeter is going to report a resistance reading between 11 to 19 Ohms if the injector and the wiring between it and the PCM are OK.

- Bad fuel injector circuit: Your multimeter is going to read one of three things: an open-circuit problem (infinite Ohms), a short-circuit problem (0 Ohms), or a resistance value that isn't within the 11 to 19 Ohms specification.

The cool thing about this initial test, we're going to do is that it helps us bypass having to remove the intake manifold plenum to access the injectors for cylinders 1, 2, and 3.

By the way, if you don't have a multimeter or you need to upgrade the one you've got, this is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

IMPORTANT: Since you'll be testing the resistance of the fuel injector circuit at the female terminals of the 60-pin PCM connector, you've got to take a few very important precautions to avoid damaging those terminals. To safely test the PCM connector without and avoid damaging its female terminals, please take a look at this guide: How To Safely Probe The PCM Connector -Without Damaging It (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

Alright, these are the test steps:

- 1

Disconnect the battery's negative cable and leave it disconnected for the entire test.

NOTE: This step is important. Don't move on to the next step without first disconnecting the negative battery cable from the battery. - 2

Disconnect the PCM from its 60-pin connector.

- 3

Set your multimeter to Ohms mode.

- 4

With your multimeter test leads —and the appropriate tool— probe between the following female terminals of the 104-pin PCM connector:

- Injector 1: Pins 58 and 37.

- Injector 2: Pins 59 and 37.

- Injector 3: Pins 39 and 37.

- Injector 4: Pins 35 and 37.

- Injector 5: Pins 15 and 37.

- Injector 6: Pins 12 and 37.

NOTE: Use the connector pinout above to locate VPWR (pin 37) and the injector pins.

- 5

Write the resistance value down on a piece of paper, and make sure you note which injector that value belongs to.

- 6

Your multimeter should report a resistance between 11 and 19 Ohms for each injector circuit.

If the meter shows an open-circuit, a short-circuit, or a resistance outside the 11–19 Ohm range, that injector circuit has a problem.

Let's analyze your multimeter test results:

CASE 1: The fuel injector resistances are within specification. This lets you know that both the injector and the wiring between it and the 60-pin PCM connector are OK.

If you're troubleshooting a rough idle or a cylinder misfire, there's a good chance the injector —even though it passed the resistance test— might be clogged. Go ahead and head over to this section for more troubleshooting tips and suggestion: How To Find The Bad Or Clogged Fuel Injector.

CASE 2: One or more fuel injectors did not register the indicated specification of 13-19 Ohms. This result confirms that you do have an issue with the fuel injector circuit, and it'll definitely cause either a rough idle condition or a cylinder misfire problem.

Our next step is to figure out if the issue is with the fuel injector itself or with the wiring between it and the PCM connector. Head over to: Checking The Injector's Resistance Directly At Its Terminals.

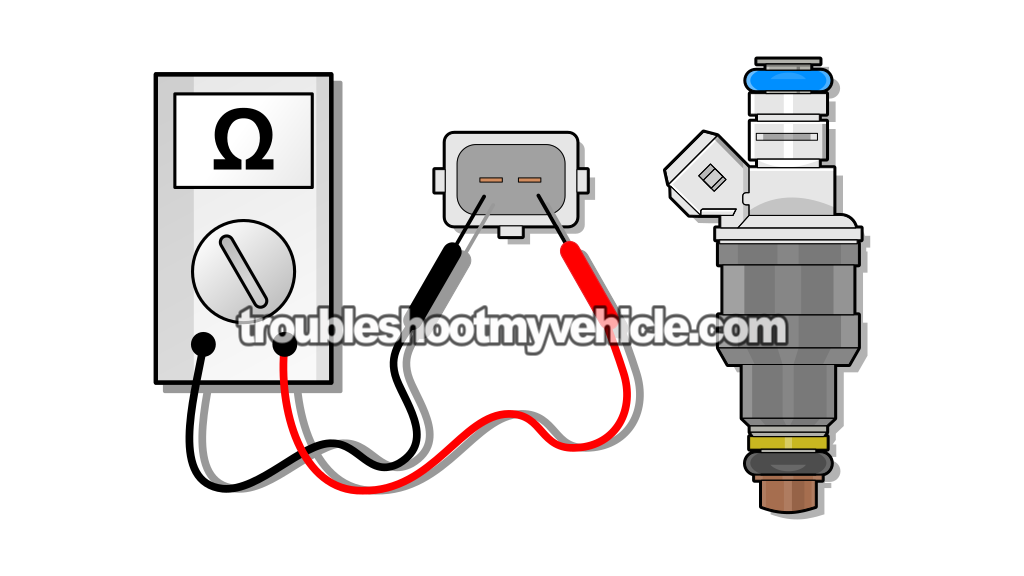

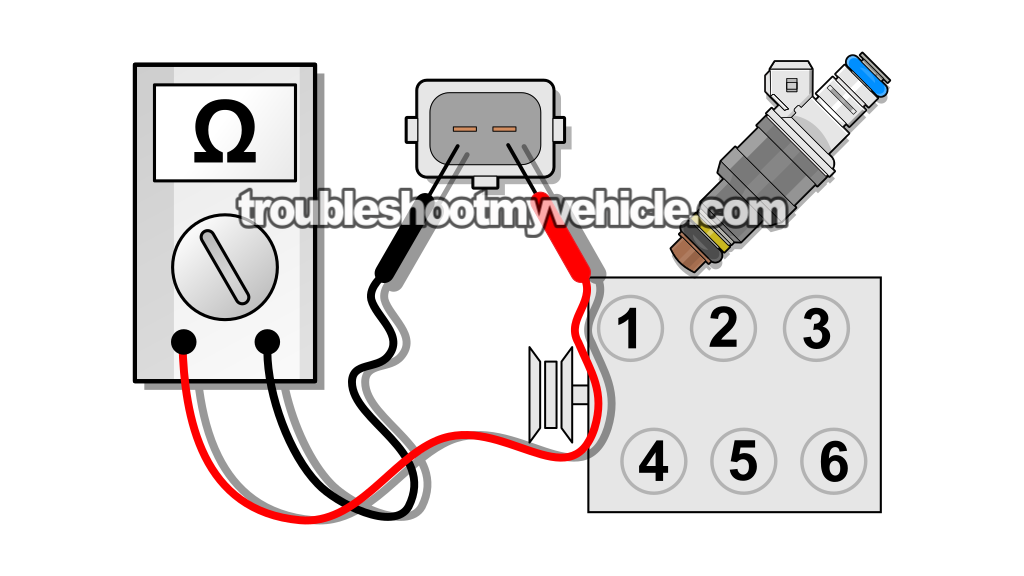

Checking The Injector's Resistance Directly At Its Terminals

When a fuel injector circuit fails TEST 1, your multimeter will usually report one of three results:

- The resistance is infinite Ohms —which tells us there's an open-circuit problem.

- The resistance is 0 Ohms —which tells us there's a short-circuit problem.

- The resistance isn't within specification (but not indicating a short or open-circuit) —this generally confirms the injector itself is worn out.

Regardless of what your multimeter is showing on its screen (when it's not reporting the specified resistance), the issue could be caused by the fuel injector itself (which is the most common scenario), or there's a problem with the wires between the injector connector and the 60-pin PCM connector. Now, the cool thing is that we can easily figure this out by doing two more checks:

- Inspect the fuel injector connector and the wires coming out of it: The injector's connector is a very common failure point on these 3.0L V6 Ford engines. What usually happens is that the insulation of the wires —right where they exit the connector— starts to peel off. Once the copper strands are exposed, they'll short together— which will give you a 0-Ohm test result in TEST 1.

- Measure the resistance directly across the injector's two terminals: By checking the resistance of the injector directly at its two terminals, we can eliminate the wiring between the injector and the PCM connector. So if you get a resistance that's not within the indicated specification, that fuel injector is toast and needs to be replaced.

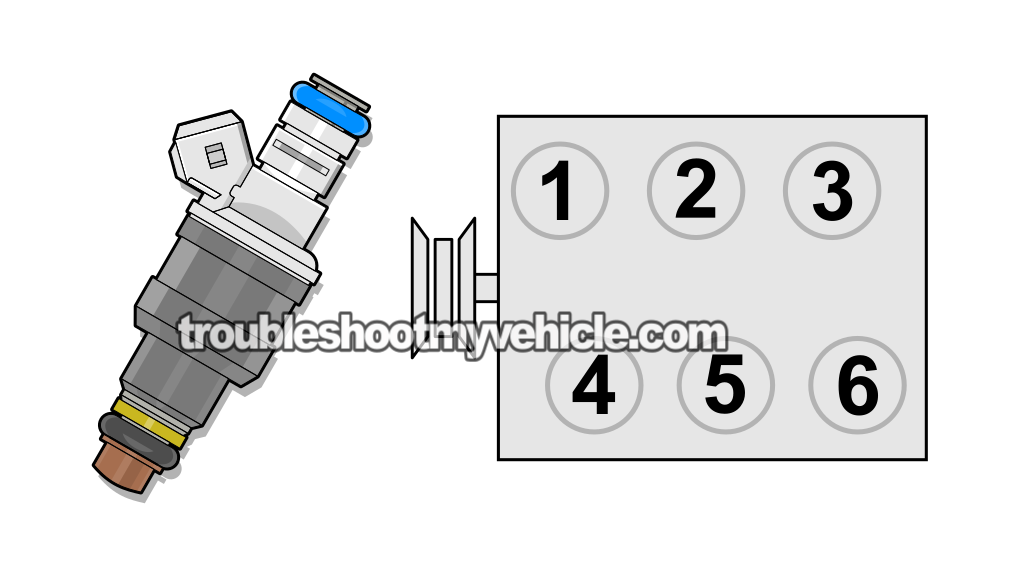

The only complication you're going to run into is if the injector you need to check is located underneath the intake manifold plenum —these are the injectors for cylinders 1, 2, and 3.

If, in your particular case, you do have to remove the plenum to check both the connector and its wiring and the resistance of the injector itself, please take a look at the following section for some important precautions you'll need to take when removing the intake manifold plenum: Precautions To Take When Removing The Intake Manifold Plenum.

How To Find The Bad Or Clogged Fuel Injector

There was a time when having to diagnose a defective fuel injector on the 3.0L Ford Taurus (Mercury Sable) made me very nervous. Especially because 3 of the 6 fuel injectors are located underneath the intake manifold plenum (and you've got to remove this bad boy to be able to access them).

Thankfully I was able to develop a strategy of tests that helped me speed up the process of finding the defective or clogged fuel injector (although in a lot of cases, the cause of the engine misfire had nothing to do with a defective or clogged fuel injector).

OK, this is the basic diagnostic strategy that I used and I think will prove helpful to you too:

- Identify the dead cylinder first.

- Finding the cylinder that's actually misfiring (dead) is the most critical first step to successfully diagnose a bad/clogged injector, or whatever is causing a cylinder misfire.

- Since the 1991-1995 Ford Taurus is OBD I equipped —in other words, no onboard misfire diagnostics— you'll have to do a manual cylinder balance test to ID the dead cylinder.

- Verify that the dead cylinder is getting spark.

- To get the most accurate test result, it's important that you use a dedicated spark tester for this test.

- You also need to remove the spark plug and check that it is not damaged in any way shape or form.

- Make sure that the spark plug boot is not damaged or covered in a carbon track. You can find out more about carbon tracks here: Carbon Tracks Are A Common Cause Of Ignition Misfires (at: easyautodiagnostics.com).

- The idea here is to make sure that the ignition system is not behind misfire problem. This tutorial will help you with those checks: Ignition Coil And Basic Ignition System Tests (1990-1995 3.0L V6 Ford Taurus, Mercury Sable).

- Once you've confirmed that the dead cylinder is getting spark then the next step is to make sure that it has good compression.

- One of the most common issues causing a cylinder misfire or a rough idle —especially in high-mileage engines— is a cylinder with low or zero compression output.

- This tutorial will help you with the compression test and more importantly, how to interpret its test results: How To Do And Interpret An Engine Compression Test (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- Check the dead cylinder's fuel injector resistance.

- This step usually comes after you've confirmed that the dead cylinder has spark and good compression. If the dead cylinder's fuel injector resistance isn't within the indicated 11 to 19 Ohms, then it's toast and is the cause of the cylinder misfire you're trying to solve.

- Check the fuel injector spray pattern.

- If after confirming that the dead cylinder is getting spark, it's got good compression, and its fuel injector's internal resistance is OK, the next step is to remove the injector and connect it to a DIY fuel injector cleaner tool (you can easily find these online) to check its spray pattern.

- This tool will help confirm if the injector is clogged —since you can see the injector's actual spray pattern. This test is a game changer! You can see an example of this tool here: Universal Fuel Injector Tester and Cleaner Tool Kit (Amazon affiliate link).

- This tutorial explains how it's done: Fuel Injector Spray Test (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

The key thing to take away from the list of tests I've outlined above is that it all boils down to a simple process of elimination. All you're doing is making sure the dead cylinder is getting spark, that it has good compression, that its fuel injector isn't fried internally, and possibly removing the injector to visually check its spray pattern. That's all there is to it.

This diagnostic strategy has been a time saver —not to mention a money saver— since it's helped me avoid the frustration of replacing parts that won't solve the issue. I'm confident it's going to help you too.

Precautions To Take When Removing The Intake Manifold Plenum

If your fuel injector circuit tests confirm that one of the injectors located underneath the intake manifold plenum isn't within the 11 to 19 Ohms specification, then you'll have to remove the plenum to inspect the injector's connector and check the resistance directly at its two terminals.

Removing the plenum isn't that difficult —it's very doable. I've done it quite a few times myself over the years. As long as you keep the following precautions in mind, you're not going to have any problems.

- Once you've removed intake manifold plenum, place clean shop towels over the lower intake manifold ports.

- As you're removing bolts (or nuts), place them in a container that's located away from the engine compartment.

- Once you're done with your tests and you're reinstalling the plenum, use new gaskets and install them without any type of sealant —such as RTV silicone.

If anything falls into any one of the 6 ports of the lower intake manifold, and you start the engine -you're gonna' be in a world of hurt. The only way to remove whatever fell into the engine is to remove the cylinder head (or heads). Also, the engine can suffer piston or cylinder head valve damage as the metal object bounces around the cylinder.

More 3.0L V6 Ford Taurus Diagnostic Tutorials

You can find a complete list of 3.0L V6 Ford Taurus and Mercury Sable tutorials in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The MAF Sensor (1991-1995 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test For A Blown Head Gasket (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- How To Do And Interpret An Engine Compression Test (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (1990-2000 3.0L V6 Ford Taurus, Mercury Sable).

If this info saved the day, buy me a beer!