In this tutorial, I'm going to show you how to test the mass air flow (MAF) sensor with a simple multimeter. Yep —no need for any expensive diagnostic equipment, not even a scan tool.

We'll go through four tests that'll help you get to the bottom of your MAF sensor issue:

- Checking the MAF signal.

- Making sure the MAF sensor is getting VPWR power.

- Making sure the sensor is getting PWR GND Ground.

- And finally, making sure the sensor is getting the MAF RTN Ground.

All of these tests can be done with a basic multimeter. And with your results, you'll quickly know whether the MAF sensor is good —or toast.

Contents of this tutorial:

- Symptoms Of A Bad MAF Sensor.

- MAF Sensor Circuit Descriptions.

- What Tools Do I Need To Test The MAF Sensor?

- TEST 1: Testing The MAF Signal.

- TEST 2: Making Sure The MAF Sensor Is Getting Power (VPWR).

- TEST 3: Making Sure The MAF Sensor Is Getting Ground (PWR GND).

- TEST 4: Making Sure The MAF Sensor Is Getting Ground (MAF RTN).

- More 3.8L V6 Ford Windstar Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.8L V6 Ford Windstar: 1995.

1996-2003 MAF SENSOR TESTS:

Symptoms Of A Bad MAF Sensor

As you probably already know, your Windstar's PCM needs to know how much air is entering the engine as it runs. And yep —it's the mass air flow (MAF) sensor that measures and sends that information to the PCM.

Since the MAF sensor is such a critical part of the engine management system, when this bad boy fails, your Windstar's performance is going to go out the window. You'll notice one or more of the following problems:

- Check engine light: The CEL will be lit on the dash, and the computer will usually store one of these OBD-I diagnostic trouble codes (DTCs):

- 157: MAF Sensor Circuit Below Minimum Voltage.

- 158: MAF Sensor Circuit Above Maximum Voltage.

- 159: MAF Higher Or Lower Than Expected.

- Lack of power: Your Windstar or Sable's engine may feel weak or hesitate when you hit the gas, especially under load or at higher speeds.

- Rough idle/stalling: The engine can idle unevenly or shut off on its own.

- Bad gas mileage: A bad MAF affects the PCM's ability to control the air-fuel mixture, making the engine run rich or lean, which kills gas mileage.

- Black exhaust smoke: If the PCM is adding too much fuel because of a bad MAF sensor signal, you may see black smoke coming out of the tailpipe.

- Hard starting: Sometimes the engine will crank but struggle to start.

- Hesitation or surging: You might feel the engine stumble or surge while accelerating or cruising.

MAF Sensor Circuit Descriptions

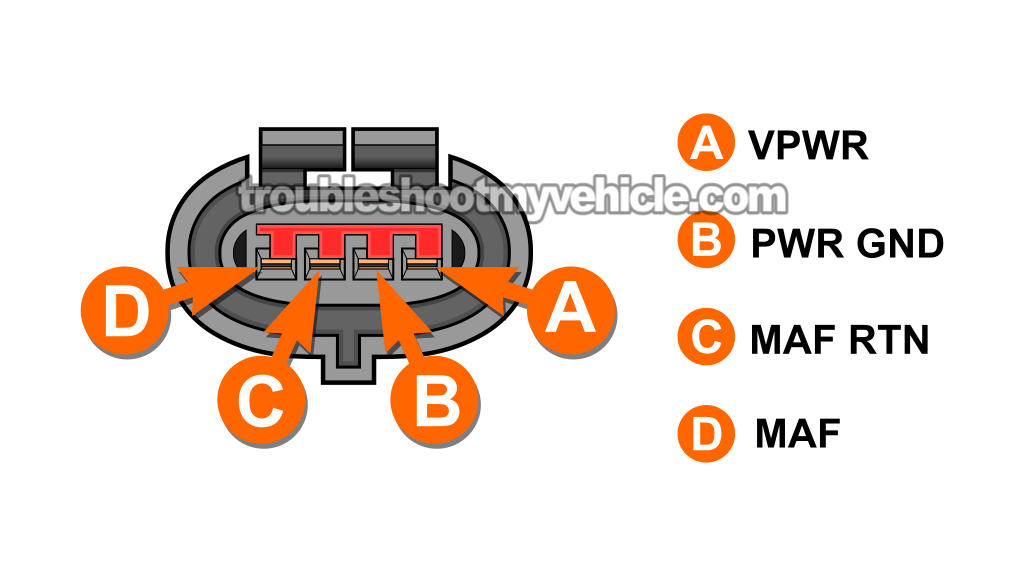

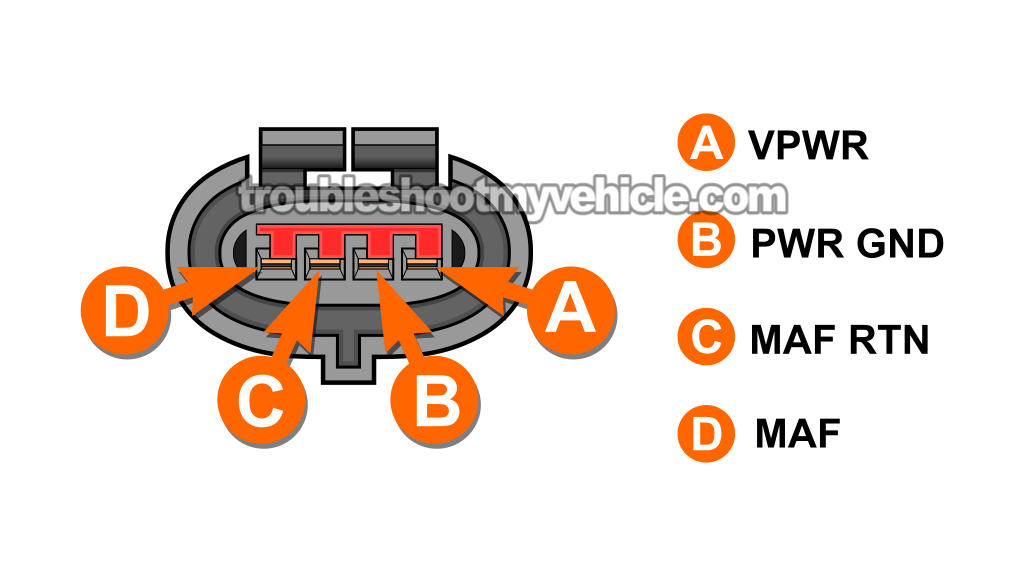

As you probably already know, the MAF sensor connector has four wires coming out of it. In the table below, you'll find a brief description of what each wire does —this info will come in handy for the tests that follow.

| Pin | Wire | Description |

|---|---|---|

| A | Red (RED) | VPWR –12 Volts Input in RUN or START |

| B | Black with white stripe (BLK/WHT) | PWR GND –Chassis Ground Input |

| C | Tan with light blue stripe (TAN/LT BLU) | MAF RTN –MAF sensor Ground (provided by PCM) |

| D | Light blue with red stripe (LT BLU/RED) | MAF –MAF signal |

What Tools Do I Need To Test The MAF Sensor?

To test the MAF sensor on your 1995 3.8L V6 Ford Windstar, you're going to need just two tools. And these are:

- A multimeter: To check the MAF signal voltage output, and verify power and Ground to the sensor.

- A wire-piercing probe or back probe: This tool lets you access the MAF signal voltage inside the MAF signal wire in TEST 1.

If you don't have a multimeter, need to upgrade yours, or don't have a wire-piercing probe kit, I recommend the same ones I personally use for my diagnostic tests. Both of these kits are inexpensive, reliable, and perfect for the kind of testing we'll be doing:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Testing The MAF Signal

The very first thing we're going to do is check the MAF sensor's signal output. To understand what we're doing, there are two key things you need to know:

- When the engine is idling, airflow into the engine is low —so the MAF sensor's signal voltage output will also be low (0.6 - 0.8 Volts).

- When engine RPM increases —like when you step on the gas pedal— the amount of air entering the engine increases, and so does the MAF sensor's signal voltage (1.4 - 2.0 Volts).

This signal voltage output is very predictable. Just remember: when RPMs go up, so does the MAF signal voltage. When RPMs go down, the signal voltage drops too —because engine speed is directly tied to how much air is entering the engine as you step on or release the accelerator pedal.

So here's what we're going to do: connect your multimeter and tap into the MAF signal wire —that's the light blue with red stripe wire. Start the engine, rev it up a couple of times, and watch what the signal voltage does.

Normally, when a MAF sensor fails, its voltage signal stays stuck at one value no matter what the engine RPM is doing.

IMPORTANT: To check the MAF signal output, the sensor has to remain connected to its 4-wire connector. This means that you'll need to use a back probe on the connector or a wire piercing probe on the wire to be able to read the MAF signal output voltage. If you don't have the appropriate tool, this is the one I use and recommend for these types of tests: Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link).

Here's what we need to do:

- 1

Set your multimeter to Volts DC mode.

- 2

Attach the black lead of the multimeter to the battery's negative (-) post.

- 3

Probe the light blue with red stripe (LT BLU/RED) wire with the red multimeter lead using either a back probe or a wire-piercing probe.

The LT BLU/RED wire connects to terminal D of the MAF sensor connector (see diagram above).

NOTE: Remember, the MAF sensor must remain connected to its 4-wire connector. - 4

Start the engine and let it idle.

Once the idle steadies out, take note of the reading on the multimeter. Some small fluctuation is normal. This value (usually around 0.6 - 0.8 Volts) is your base MAF signal voltage. - 5

Increase engine speed by opening the throttle.

You can do this directly at the throttle body by moving the linkage, or by having a helper press the accelerator pedal. - 6

The MAF signal voltage should climb as RPM rises.

- 7

Let go of the throttle so the RPM drops back down.

- 8

The signal voltage should decrease as RPM falls.

- 9

Repeat the rev-up/release cycle a few times to make sure the readings are consistent.

Here's what your test results mean:

CASE 1: The signal voltage rose as engine speed went up and dropped back down when you released the throttle. This test result tells you that your Windstar's MAF sensor is doing its job and working correctly.

So, if you've got a code 157 (MAF Signal Below Minimum Voltage) or code 158 (MAF Signal Above Maximum Voltage) stored in the PCM's memory, whatever triggered that code isn't happening right now.

Why? Because the MAF signal isn't stuck low or high —it's responding to changes in engine RPM as you rev up and down. At this point, the sensor is working properly.

CASE 2: The signal voltage stayed fixed at one value no matter how the engine speed changed. This result usually means the MAF sensor has kicked the bucket.

To make sure the sensor is bad, we need to make sure it's getting power and Ground. The next step is: TEST 2: Making Sure The MAF Sensor Is Getting Power (VPWR).

TEST 2: Making Sure The MAF Sensor Is Getting Power (VPWR)

Like any other electrical component on your Windstar's engine, the MAF sensor needs power to operate and produce its output signal. Specifically, the sensor's hot wires require 12 Volts to function.

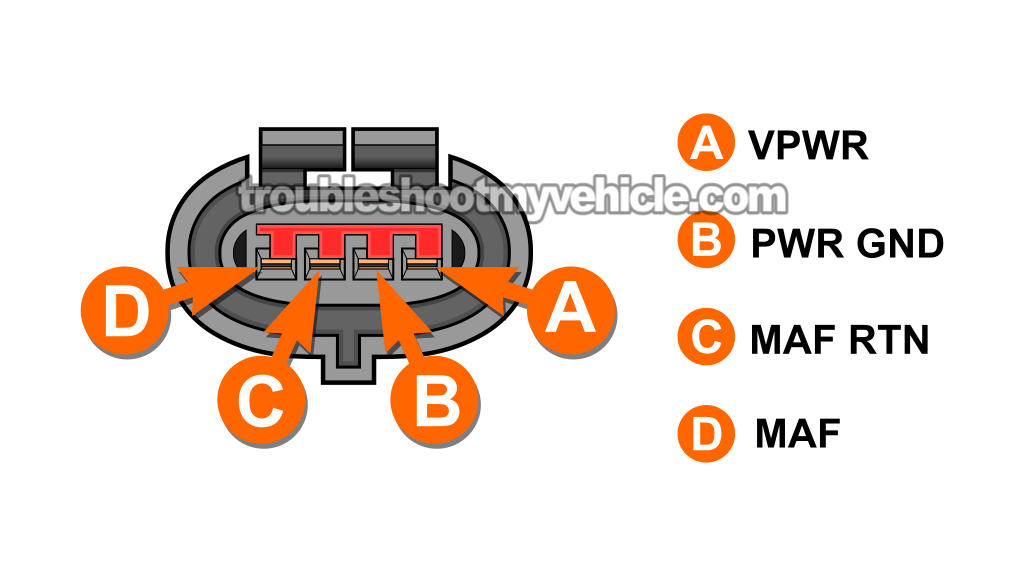

The wire that delivers this VPWR power to the MAF sensor is the red (RED) wire, which connects to female terminal A of the MAF sensor's 4-wire connector.

This VPWR power is only available at the RED wire —and at terminal A— when the key is in the RUN or START position.

For our VPWR test, we'll check for it with the key in the RUN position but with the engine OFF.

Once we've confirmed that 10 to 12 Volts are present at terminal A, we'll move on to check that terminal B is providing the PWR GND Ground.

IMPORTANT: Be careful when probing the front of the terminal with your multimeter test leads. If the test lead is too thick, it could permanently open up the terminal. If that happens, you'll need to replace the connector.

Let's begin:

- 1

Unplug the MAF sensor from its electrical connector.

- 2

Set your multimeter to Volts DC.

- 3

Attach the black multimeter lead to the battery's negative (-) post.

- 4

Carefully probe female terminal number A with the red multimeter lead.

Terminal A should correspond to the RED wire on the MAF sensor's 4-wire connector. - 5

Turn the ignition key to RUN, but don't crank or start the engine.

- 6

The multimeter should read between 10 and 12 Volts.

Here's how to read your results:

CASE 1: The multimeter showed 10 to 12 Volts. Good —this is the correct result, and it tells us the MAF sensor is getting power.

Now that we've confirmed VPWR power at terminal A, our next step is to make sure the hot wires are getting PWR GND Ground at terminal B. For this test, head over to: TEST 3: Making Sure The MAF Sensor Is Getting Ground (PWR GND).

CASE 2: The multimeter did not show 10 to 12 Volts. If you don't see 10 to 12 Volts at terminal A, double-check that you're testing the correct terminal and repeat the test.

If you still don't get voltage, you can rule out the MAF sensor itself as bad —because without this VPWR power, it simply can't function.

Although it's beyond the scope of this tutorial, your next step would be to find out why the RED wire isn't delivering those 10 to 12 Volts and repair the issue. Once the sensor gets power again, it'll function normally and the MAF diagnostic trouble code will clear.

TEST 3: Making Sure The MAF Sensor Is Getting Ground (PWR GND)

Alright, besides the 10 to 12 Volts of VPWR power, your Windstar's MAF sensor hot wires also need a solid chassis Ground (PWR GND) to function.

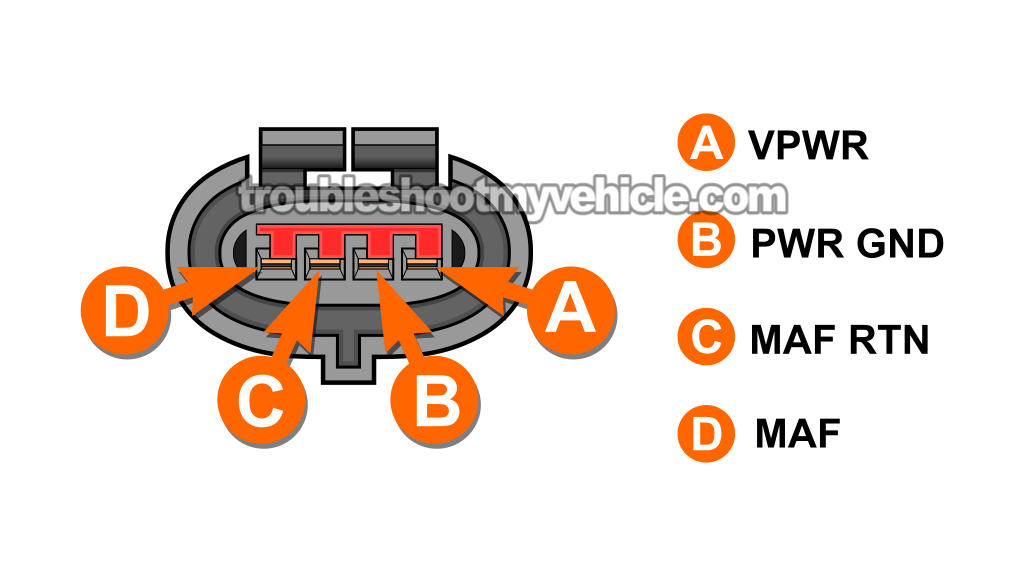

The wire that provides this direct path to chassis Ground is the black with white stripe (BLK/WHT) wire on the MAF sensor's 4-wire connector. This BLK/WHT wire connects to female terminal B of the connector.

Since this is a chassis Ground supplied through terminal B, it's available at all times —regardless of the ignition key position.

To check for this PWR GND chassis Ground, we're going to do a simple multimeter voltage test at terminal B.

IMPORTANT: Be careful when probing the front of the connector or female terminal with the multimeter test lead.

Alright, let's begin:

- 1

Disconnect the MAF sensor from its electrical connector.

- 2

Switch your multimeter to Volts DC.

- 3

Connect the red lead of the multimeter to the battery positive (+) terminal.

- 4

Lightly probe female terminal B with the black lead of the multimeter.

Terminal 3 should match up with the BLK/WHT wire at the MAF sensor connector. - 5

The multimeter should read between 10 and 12 Volts.

NOTE: Since this is a chassis Ground, it'll be present at all times —whether the key is OFF, RUN, or START.

Here's how to interpret your readings:

CASE 1: The multimeter shows 10 to 12 Volts. Awesome —this multimeter test result confirms the MAF sensor has a solid connection to chassis Ground.

Now we can move on to our final test, which is making sure the Powertrain Control Module (PCM) is providing a MAF RTN Ground at terminal C. For this test, head over to: TEST 4: Making Sure The MAF Sensor Is Getting Ground (MAF RTN).

CASE 2: The multimeter does not show 10 to 12 Volts. If terminal B isn't supplying a path to chassis Ground, then the MAF sensor itself won't function.

Although it's beyond the scope of this tutorial, your next step would be to figure out why this chassis Ground is missing and restore it to the circuit. Once the sensor gets its chassis Ground back, it'll function normally, and the MAF diagnostic trouble code should clear.

TEST 4: Making Sure The MAF Sensor Is Getting Ground (MAF RTN)

If you've reached this point, you've confirmed the following:

- The MAF signal is stuck, regardless of engine RPM (TEST 1).

- Terminal A is delivering VPWR voltage (TEST 2).

- Terminal B is providing PWR GND Ground (TEST 3).

Our final diagnostic check of your Windstar's MAF sensor is to make sure the PCM is delivering MAF RTN Ground to terminal C.

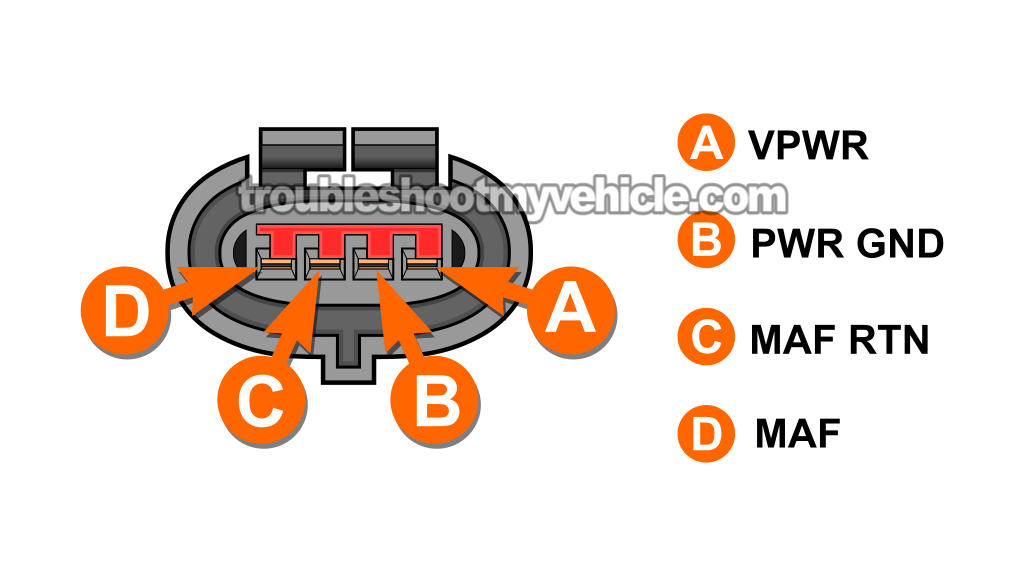

This MAF RTN Ground is provided internally by the PCM and sent to terminal C through the tan with light blue stripe (TAN/LT BLU) wire.

To check for the presence of this PCM-supplied MAF RTN Ground, we're going to do a simple multimeter voltage test at terminal C.

CAUTION: Since the MAF RTN Ground is provided by the PCM itself, you need to be careful when testing this circuit. Do not apply 12 Volts directly from the battery to it, or you'll fry the PCM. The test I'm describing below is a safe and easy way to check for Ground at terminal C.

OK, these are the test steps:

- 1

Unplug the MAF sensor from its connector.

- 2

Set your multimeter to Volts DC.

- 3

Attach the red multimeter lead to the battery positive (+) post.

- 4

Carefully probe female terminal C with the black multimeter lead.

Terminal C should match up with the TAN/LT BLU wire of the MAF sensor connector. - 5

Turn the key to the RUN position, but don't crank or start the engine.

- 6

The multimeter should register between 10 and 12 Volts.

Here's how to interpret your readings:

CASE 1: The multimeter showed 10 to 12 Volts. This is the correct and expected test result, and it tells you the PCM is supplying the MAF RTN signal the sensor needs to function.

We can conclude that the MAF sensor is bad and needs to be replaced only if all of the following conditions are true:

- The MAF signal voltage output stays stuck at one value, regardless of engine RPM (TEST 1).

- The sensor is getting VPWR voltage from terminal A (TEST 2).

- The sensor is getting PWR GND Ground from terminal B (TEST).

- And, as confirmed in this test, terminal C is supplying the MAF RTN Ground.

CASE 2: The multimeter did not show 10 to 12 Volts. Double-check that you're probing the correct terminal on the connector and repeat the test.

If you still don't see the presence of the MAF RTN Ground at terminal C, then you can rule out the MAF sensor itself as being bad and the cause of the MAF trouble code that's turning on the check engine light.

Although it's beyond the scope of this tutorial, your next step is to figure out why the PCM isn't supplying this Ground (and restore it to the circuit). The most likely cause of the missing MAF RTN Ground is an open-circuit in the TAN/LT BLU wire between the MAF sensor connector and the PCM.

More 3.8L V6 Ford Windstar Diagnostic Tutorials

You can find a complete list of 3.8L V6 Ford Windstar and Mercury Sable diagnostic tutorials in this index:

Here's a sample of the diagnostic tutorials you'll find in the index:

- How To Test The Fuel Pump (1995-1998 3.8L V6 Ford Windstar).

- How To Test For A Blown Head Gasket (1995-2003 3.8L V6 Ford Windstar).

- How To Test The TPS (1996-1999 3.8L V6 Ford Windstar).

- How To Do And Interpret An Engine Compression Test (1995-2003 3.8L V6 Ford Windstar).

If this info saved the day, buy me a beer!