Seeing a trouble code P0171 or P0174 (or both) lighting up the check engine light in your van can be a bit of a 'head thumper', since quite a few things can cause them.

In this tutorial, which I've written specifically for the 2003-2013 Chevy Express/GMC Savana with a 4.8L, 5.3L, or 6.0L engine, I'll walk you through the meaning of these codes and the most common fixes for this problem.

Let's get started!

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- Chevrolet Express 1500, 2500, 3500: 2003, 2004, 2005, 2006, 2007, 2008, 2009, 2010, 2011, 2012, 2013.

- GMC Savana 1500, 2500, 3500: 2003, 2004, 2005, 2006, 2007, 2008, 2009, 2010, 2011, 2012, 2013.

What Do Trouble Codes P0171 And P0174 Mean?

P0171 and P0174 are both related to the fuel system in your vehicle, specifically indicating a lean air/fuel mixture condition. Here's what each code means:

P0171:

- P0171: Lean Air/Fuel Mixture In Bank 1. This code indicates that the engine is running too lean on bank 1.

- Bank 1 Location: The V8 engine in your van has two banks of cylinders (bank 1 and bank 2). Bank 1 refers to the side of the engine where cylinders 1, 3, 5, and 7 are located.

- Lean Air/Fuel Mixture: A lean condition means there's too much air and not enough fuel in the air-fuel mixture being delivered to the engine cylinders.

- Symptoms: A lean air/fuel mixture can lead to a variety of symptoms including rough idle, hesitation during acceleration, poor fuel economy, and even engine misfires in severe cases.

P0174:

- P0174: Lean Air/Fuel Mixture In Bank 2. This code indicates that the engine is running too lean on bank 2.

- Bank 2 Location: Bank 2 refers to the side of the engine where cylinders 2, 4, 6 and 8 are located.

- Lean Air/Fuel Mixture: A lean condition means there's too much air and not enough fuel in the air-fuel mixture being delivered to the engine cylinders.

- Symptoms: A lean air/fuel mixture can lead to a variety of symptoms including rough idle, hesitation during acceleration, poor fuel economy, and even engine misfires in severe cases.

The "air/fuel mixture" refers to the combination of air and gasoline that's sprayed into the engine cylinders for combustion.

Now, getting the right mix of air and fuel is super important. If there's too much air and not enough fuel, we call that a "lean" air/fuel mixture. On the other hand, if there's too much fuel and not enough air, that's a "rich" air/fuel mixture.

The powertrain control module (PCM) is the component that handles the air/fuel mixture. It's constantly monitoring things like how much air is coming into the engine (with sensors like the mass airflow sensor) and how much oxygen is in the exhaust (with oxygen sensors). Based on this and other info, the PCM adjusts how much fuel gets sprayed into the cylinders to keep that mixture just right.

When the PCM detects that the mixture is too lean (not enough fuel), it'll throw trouble codes like P0171 and P0174 to let you know something's up. It might try to compensate by adding more fuel, but if there's a problem like a vacuum leak or a faulty sensor, it can't always fix it on its own.

What Causes Trouble Codes P0171 And P0174?

The most common causes of codes P0171 and P0174 include:

- Vacuum Leaks: Vacuum leaks occur when there's an unintended gap or hole in the intake system of the engine, allowing extra unmetered air to enter it. This disrupts the air/fuel mixture, leading to a lean condition and triggering codes P0171 and P0174.

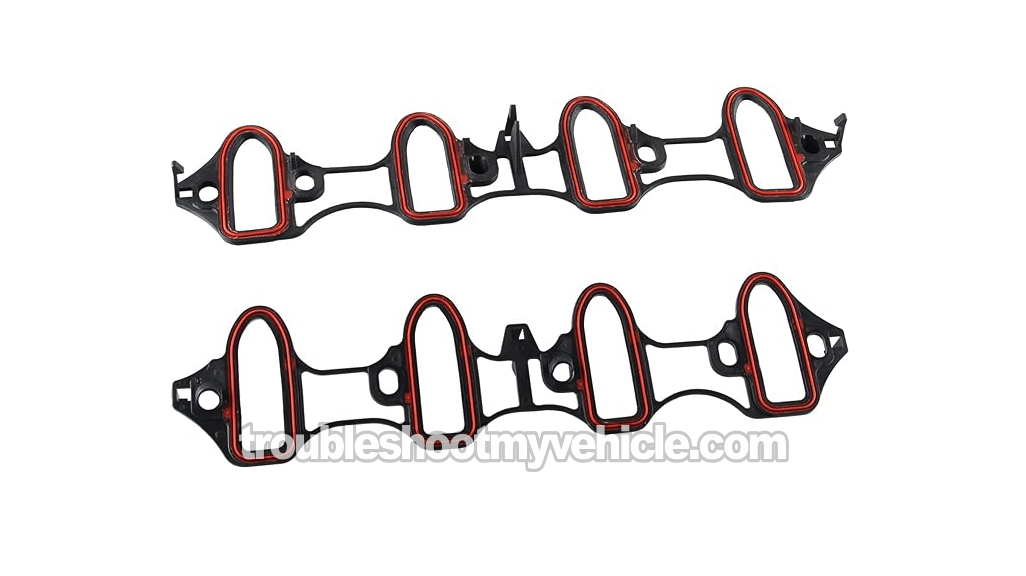

- Intake Manifold Gaskets: Over time, due to exposure to heat, engine fluids, and other environmental factors, intake manifold gaskets (which are made of a composite material -plastic- and rubber) will harden and become brittle. As a result, the gaskets no longer provide a proper seal between the intake manifold and the cylinder heads. Faulty intake manifold gaskets are a common issue, disrupting the carefully metered air/fuel mixture and leading to a lean condition.

- Dirty or Malfunctioning Mass Airflow Sensor (MAF): The mass airflow sensor measures the amount of air entering the engine and sends this data to the PCM, which then calculates the appropriate amount of fuel to inject. If the MAF sensor is dirty or malfunctioning, it may provide inaccurate readings, leading to an incorrect air/fuel mixture and triggering lean condition codes.

- Faulty Fuel Pump: A weak or failing fuel pump might not deliver enough fuel pressure, leading to a lean mixture. It's not uncommon for a faulty fuel pump to deliver enough fuel to start the engine, but not enough for it to function optimally under load.

- Faulty Oxygen Sensors: Oxygen sensors (O2 sensors) are responsible for measuring the amount of oxygen in the exhaust gases. This information is used by the PCM to adjust the air/fuel mixture. If an oxygen sensor is faulty or not functioning properly, it can provide incorrect data to the PCM, leading to a lean condition and the appearance of P0171 and P0174 codes.

- Exhaust Leaks: Exhaust leaks, particularly those located near the oxygen sensors, can introduce extra air into the exhaust system. This can affect the readings of the oxygen sensors, leading to incorrect adjustments by the PCM and triggering lean condition codes.

- Dirty Fuel Injectors: Over time, fuel injectors can become clogged with deposits, reducing fuel flow and causing a lean condition. Regular cleaning or injector replacement may be necessary.

It's a pretty big list, however, in my experience, vacuum leaks somewhere in the engine's intake system are often the most common culprit I've found behind trouble codes P0171 and P0174.

How To Resolve Trouble Code P0171 Or P0174

It'll take a bit of trial and error to pinpoint the exact issue of the engine's lean air/fuel mixture. I'm not saying you'll need to run out and start buying things to throw at the engine. No, not at all!

There's is a method to the madness and it all starts by checking for vacuum leaks around the intake manifold and the hoses that connect to it (thankfully, there aren't that many).

- Checking for Vacuum Leaks Around The Intake Manifold: This test involves visually inspecting the intake manifold and associated vacuum hoses for any signs of damage, wear, or disconnected components. You're looking for cracks, splits, or loose connections that could allow unmetered air to enter the engine, disrupting the air/fuel mixture.

- Smoke Test With A Smoke Machine: In professional repair shops, a smoke test the method of choice for detecting hidden vacuum leaks. A smoke machine is used to introduce a controlled amount of smoke into the intake manifold and associated vacuum lines. The technician then observes for any smoke escaping from cracks, leaks, or faulty seals, indicating the presence of a vacuum leak.

- Using Propane or Starting Fluid: Another common method for detecting vacuum leaks is to use propane or starting fluid around the intake manifold gasket areas. If there's a vacuum leak, the engine will draw in the propane or starting fluid, causing a temporary change in the air/fuel mixture. You can observe changes in engine speed or listen for changes in engine idle to identify potential vacuum leaks.

- Fuel Pressure Test: This test evaluates the fuel pressure within the fuel system to ensure it's within the manufacturer's specified range. A fuel pressure gauge is connected to the fuel rail, and the engine is run to observe the pressure readings. If the fuel pressure is too low, it can indicate issues such as a faulty fuel pump, clogged fuel filter, or fuel pressure regulator problems, which can contribute to a lean condition. The following tutorials explain how to test the fuel pump:

- Testing the Oxygen Sensors: Oxygen sensors (O2 sensors) play a crucial role in monitoring the oxygen content in the exhaust gases. A scan tool is used to monitor the oxygen sensor readings while the engine is running. Additionally, a common test involves inducing a temporary rich condition by spraying starting fluid or propane into the intake manifold while monitoring the oxygen sensor readings. If the oxygen sensors respond appropriately to the rich mixture by showing a temporary increase in voltage, it indicates that the sensors are functioning correctly. However, if the sensors fail to respond, it suggests a faulty oxygen sensor is the cause behind the lean condition.

- MAF Sensor Inspection: The mass airflow sensor (MAF) measures the amount of air entering the engine and plays a crucial role in determining the air/fuel mixture. Inspecting the MAF sensor for dirt, debris, or damage and cleaning it if necessary can help ensure accurate airflow measurements and prevent lean conditions caused by MAF sensor malfunction.

- Exhaust Leaks: Exhaust leaks occur when there are gaps or holes in the exhaust system that allow exhaust gases to escape before reaching the oxygen sensors. These leaks can introduce extra oxygen into the exhaust stream, leading to false readings from the oxygen sensors. This can cause the PCM to incorrectly adjust the air/fuel mixture, potentially resulting in a lean condition.

Solving diagnostic trouble codes like P0171 and P0174 often involves a systematic process of elimination. You'll want to start with the most obvious and basic checks, and then move up to testing the more 'complicated components'.

What Tools Do I Need?

Here's a list of the basic tools you'll need:

- OBD-II Scanner: An OBD-II scanner is a must-have tool for reading diagnostic trouble codes (DTCs) stored in your vehicle's onboard computer (PCM). You can use the scanner to retrieve codes like P0171 and P0174, as well as view live data, which can provide valuable information about engine parameters such as fuel trims, oxygen sensor readings, and more.

- Multimeter: A multimeter is a versatile tool that can be used to test sensors for proper operation and continuity of electrical circuits.

- Smoke Machine or Propane/Starting Fluid: While not essential, a smoke machine or propane/starting fluid can be helpful for diagnosing vacuum leaks. A smoke machine is used to introduce smoke into the intake system to detect leaks. It's a much safer process than using propane or starting fluid to check for vacuum leaks.

- Fuel Pressure Test Gauge: Testing the fuel pressure allows you to determine whether the fuel pump is operating within the manufacturer's specified range. If the fuel pressure is low, the air/fuel mixture will be lean and cause engine performance issues.

- Basic Hand Tools: You'll also need standard hand tools like screwdrivers, pliers, socket set, and wrenches may also be necessary for performing various tests and repairs.

The prevalence of plastic intake manifold systems using rubber gaskets to seal them against the cylinder heads in the Express or Savana engines (4.8L, 5.3L, and 6.0L) has made vacuum leaks a very common issue. Thankfully, the affordability of smoke machines has become a game-changer in diagnosing these problems for the DIYer and small auto repair shop.

More Chevy Express/GMC Savana Articles And Tutorials

You can find a complete list of articles and diagnostic tutorials for the V8 Chevy Express and GMC Savana here:

Here's a sample of the tutorials you'll find in the index:

- How To Test For The Fuel Pump (2008-2013 V8 Chevy Express, GMC Savana).

- How To Test For A Blown Head Gasket (2003-2013 V8 Chevy Express, GMC Savana).

- How To Diagnose An Engine Cranks But Does Not Start Problem (2003-2007 V8 Chevy Express, GMC Savana).

- How Can I Tell If The Automatic Transmission Is Bad? (2003-2013 Chevrolet Express, GMC Savana).

If this info saved the day, buy me a beer!