In this tutorial, I'll guide you through testing the radiator fan motor on the 1997-1999 2.0L Dodge/Plymouth Neon, which is a crucial first-step in diagnosing an engine overheating problem.

Once you've confirmed that the radiator fan motor is good or bad, the next step is to check the performance of the PWM fan relay.

Content of this tutorial:

- Symptoms Of A Bad Radiator Fan Motor.

- Radiator Fan Motor Basics.

- PWM Fan Relay Connector Circuits.

- TEST 1: Checking The Fan Motor's Amperage Draw.

- TEST 2: Checking For 12 Volts At Terminal 4 Of The PWM Fan Relay Connector.

- TEST 3: Jumpering Terminals 3 And 4 Of The PWM Fan Relay.

- TEST 4: Making Sure The Radiator Fan Motor Is Getting Power.

- TEST 5: Making Sure The Radiator Fan Motor Is Getting Ground.

ES ![]() You can find this tutorial in Spanish here: Cómo Probar El Motor Del Ventilador Del Radiador (1997-1999 2.0L SOHC Dodge/Plymouth Neon) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Motor Del Ventilador Del Radiador (1997-1999 2.0L SOHC Dodge/Plymouth Neon) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 2.0L Dodge Neon: 1997, 1998, 1999.

- 2.0L Plymouth Neon: 1997, 1998, 1999.

PWM FAN RELAY TEST: You can find the PWM fan relay tests here:

Symptoms Of A Bad Radiator Fan Motor

As the radiator fan motor ages, its bearings/bushings wear out. Not only that but dirt, dust, and debris can accumulate inside the motor housing. This accumulation of dirt and wear on the bearings/bushings increases friction within the motor.

More friction means the motor has to work harder to overcome it, which results in higher amperage draw. Increased friction also generates heat, which can further accelerate wear and reduce the efficiency of the fan motor. Eventually, these factors will lead to a radiator fan motor that no longer functions.

Here are some of the symptoms you'll see when the radiator fan motor stops working:

- Overheating Engine: The primary job of the radiator fan is to keep the engine cool. If it's not working, the engine will overheat.

- Coolant Boiling Over: If the fan isn’t cooling the engine, the coolant can get too hot and boil over and leak from the coolant reservoir or radiator.

- Warning Lights: The temperature light on the dashboard will illuminate or the temperature gauge will max out to indicate overheating from the non-functioning radiator fan.

- Unusual Sounds: Sometimes, a failing radiator fan motor might produce unusual noises if it's trying to run but encountering resistance.

Radiator Fan Motor Basics

Generally, I don't include a section like this, but in the case of the 1997-1999 Neon, it's important to know two important details:

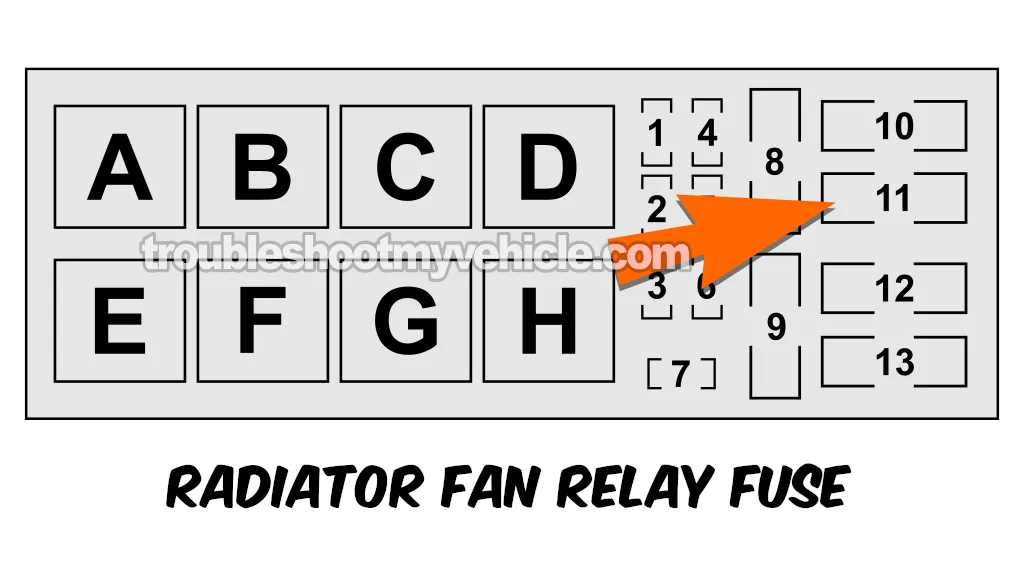

- The radiator fan motor or motors' power circuit is protected by a 30 Amp fuse (fuse #11 of the Power Distribution Center).

- The radiator fan motor or motors are activated by a PWM (Pulse Width Modulation) fan relay.

- The PWM fan relay is a solid-state component.

Given that the fan motor power circuit is protected by a 30 Amp fuse, it's clear that the amperage draw of the fan motor or motors can not be 30 Amps or more. And as you read in the previous section, when the fan motor or motors wear out and fail, they're gonna consume 30 or more Amps.

In the 1995-1996 Neon cooling system, which uses the old-style mechanical fan relay, if the radiator fan motor or motors drew 30 Amps or more, the 30 Amps fan relay fuse would simply get blown and nothing more expensive would happen. Not so in the PWM fan relay equipped Dodge/Plymouth Neon!

In the PWM fan relay equipped Neon, if the fan motor or motors exceed the 30 Amp limit, the PWM fan relay is the one that gets fried and not the 30 Amp fan relay fuse (fuse #11 of the Power Distribution Center).

Should you find, after completing the tests outlined in this tutorial, that the fan motor or motors are drawing 30 or more Amps, there's a 99% chance you'll also need to replace the PWM fan relay.

PWM Fan Relay Connector Circuits

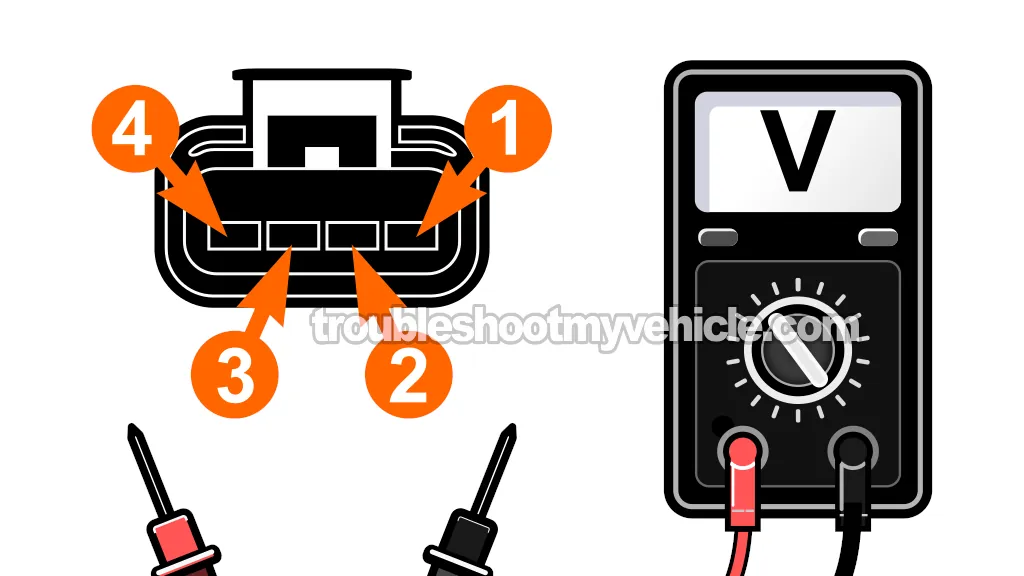

The illustration of the PWM fan relay connector is a front view of the connector (female terminal view). The connector has four wires coming out of it. Here's a description of each:

| Wire | Color | Description |

|---|---|---|

| 1 | Black (BLK) | Ground |

| 2 | Dark Green (DK GRN) | Radiator Fan Relay Control PWM Signal |

| 3 | Light green (LT GRN) | Radiator Fan Relay Output To Fan Motor Or Motors |

| 4 | Grey (GRY) | 12 Volts (from fuse #11 Power Distribution Center) |

LOCATION OF PWM FAN RELAY: The radiator fan relay is located in the engine compartment, near the driver's side front wheel well. It's mounted with two small bolts to the inner side of the left frame rail under the battery.

Fuse #11 is a 30 Amps fuse and located in the Power Distribution Center. You can find a complete listing of the locations and descriptions of the fuses and relays of the Power Distribution Center here:

TEST 1: Checking The Fan Motor's Amperage Draw

The first thing we'll do is determine the amount of amperage the radiator fan motor is drawing. If your Neon is equipped with a dual fan motor setup, you'll need to test them both.

To interpret your amperage draw test result, you need to know that the circuit that feeds current to the fan motor or fan motors is protected by a 30 Amp fuse (fuse #11 of the Power Distribution Center).

Since the circuit is protected by a 30 Amp fuse, the total amount of current used by a single or dual fan motor setup has to be under 30 Amps. Any current draw at 30 or more Amps, and we've got a problem.

On the dual radiator fan motor setup, we'll need to add the amperage draw of each fan motor together to get the total amperage draw of the circuit.

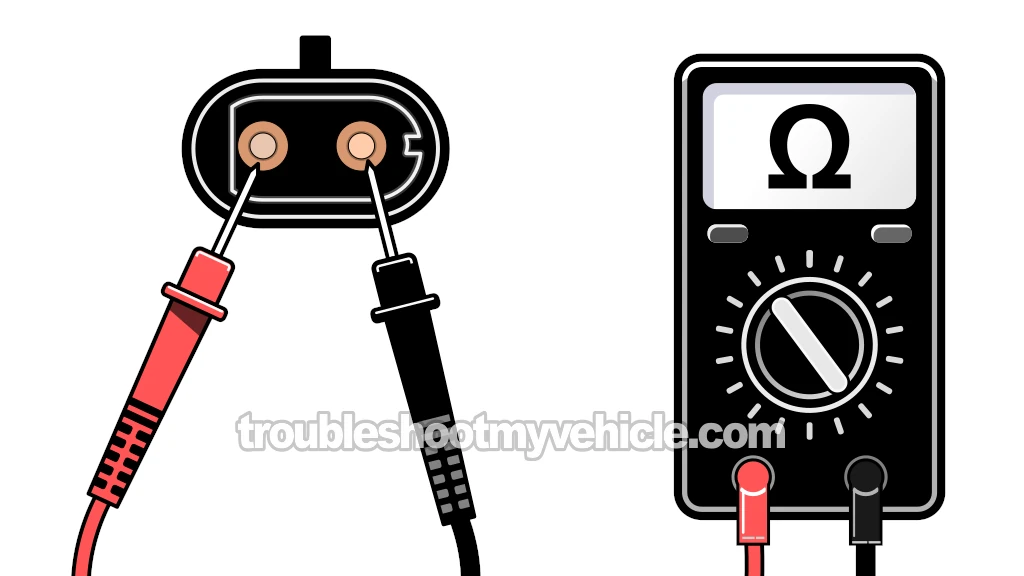

Determining the amperage draw of the radiator fan motor is an easy and straightforward thing. To determine the amperage draw, we'll measure the internal resistance of the fan motor with a multimeter.

With that multimeter resistance reading, we'll then apply Ohm's Law to determine the fan motor's amperage draw. In the test instructions below, I'll explain the whole process in detail.

These are the test steps:

- 1

Disconnect the fan motor from its electrical connector.

- 2

Set your multimeter to Ohms mode.

- 3

Measure the fan motor's resistance by probing its two male terminals with the multimeter test leads.

NOTE: It's important that the fan blades do not turn while taking a reading of the fan motor's resistance.

IMPORTANT: This test is done on the male terminals of the fan motor itself and not on its electrical connector. - 4

Write the Ohms value down on a piece of paper once the Ohms reading on your multimeter stabilizes.

- 5

Divide 12.5 by your resistance value.

The result of this calculation is the amount of amperage the fan motor is using.

To be a little more specific: Let's say that the resistance reading was 0.4 Ohms. This is what the math would look like: 12.5 ÷ 0.4 = 31.25 and this would translate to 31.25 Amps. - 6

Repeat the test steps on the other radiator fan motor (if equipped).

Let's interpret your test result:

CASE 1: (Single Fan Motor Setup) The radiator fan motor's amperage draw is under 30 Amps. This is the correct and expected test result.

The next step is to check that the radiator fan motor relay is getting 10 to 12 Volts. For this test go to: TEST 2: Checking For 12 Volts At Terminal 4 Of The PWM Fan Relay Connector.

CASE 2: (Single Fan Motor Setup) The fan motor's amperage draw is at or above 30 Amps. This tells you that the radiator fan motor has a lot of wear and tear (internally) and you can conclude it's bad and needs replacement.

Getting an amperage draw result of 30 Amps or more is a tell-tale sign of heavy internal wear and tear within the radiator fan motor. Even if the fan motor runs, it’s gonna fry the PWM fan relay (if it hasn't already).

Your next step is to test the PWM fan relay. You can find the test here:

CASE 3: (Dual Fan Motor Setup) The amperage draw of both fan motors added together is under 30 Amps. This is the correct and expected test result.

The next step is to check that the radiator fan motor relay is getting 10 to 12 Volts. For this test go to: TEST 2: Checking For 12 Volts At Terminal 4 Of The PWM Fan Relay Connector.

CASE 4: (Dual Fan Motor Setup) The amperage draw of both fan motors added together is at or above 30 Amps. This tells you that the radiator fan motors are overloading the circuit and this is not good.

More than likely, it's just one of the fans that is bad (the one with the higher amperage draw). My suggestion is to replace them both.

The number one cause of a PWM fan relay failure is the excessive amperage draw from both fan motors. With this test result, you'll need to test the PWM fan relay and see if it's fried or not:

TEST 2: Checking For 12 Volts At Terminal 4 Of The PWM Fan Relay Connector

So far, you've checked the amperage draw of the radiator fan motor (or fan motors). The next step is to make sure that the PWM fan relay is getting 12 Volts from fuse #11 of the Power Distribution Center (see illustration 2 of 2 above).

The wire that supplies these 10 to 12 Volts to the PWM fan relay is the grey (GRY) wire of the relay's connector.

In the illustration of the PWM fan relay connector above, I've labeled the female terminal that gets this voltage from fuse #11 with the number 4.

We need to make sure that 10 to 12 Volts are present at terminal 4 during this test because, in TEST 3, we'll jumper terminals 4 and 3 to channel 12 Volts directly to the fan motor and check if the fan motor runs.

NOTE: You can find the descriptions/locations of all the fuses and relays of the Power Distribution Center here: Power Distribution Center (1997-1999 Dodge/Plymouth Neon).

LOCATION OF PWM FAN RELAY: The radiator fan relay is located in the engine compartment, near the driver's side front wheel well. It's mounted with two small bolts to the inner side of the left frame rail under the battery.

Let's get started:

- 1

Locate the PWM fan relay.

- 2

Disconnect the relay from its electrical connector.

- 3

Place the multimeter in Volts DC mode.

- 4

Connect the black multimeter test lead to the battery negative (-) terminal.

- 5

Gently probe the terminal labeled with the number 4 of the PWM fan relay's connector with the red multimeter test lead.

IMPORTANT: Be careful not to damage the female terminal with the multimeter's test lead, or you'll need to replace the connector. - 6

Your multimeter should report 10 to 12 Volts DC.

NOTE: This voltage is available at all times, no need to turn the key to the RUN position.

Let's interpret your test result:

CASE 1: 10 to 12 Volts are present. This is the correct and expected test result. Your next step is to go to: TEST 3: Jumpering Terminals 3 And 4 Of The PWM Fan Relay.

CASE 2: 10 to 12 Volts ARE NOT present. This usually means that the radiator fan motor fuse (FUSE 11) is blown.

Check and replace the fuse (if necessary) and repeat the test. Once power is restored, go to: TEST 3: Jumpering Terminals 3 And 4 Of The PWM Fan Relay.