Diagnosing a faulty fuel injector on the 1989–1991 Dodge Ram pickup with the 3.9L V6 TBI system isn't complicated nor difficult.

In this tutorial, I'll walk you through a step-by-step approach I've personally used to diagnose a bad fuel injector. It's simple, effective, and you don't need any expensive diagnostic tools.

Contents of this tutorial:

- Symptoms Of A Bad Fuel Injector.

- Where To Buy The Fuel Injector And Save.

- TEST 1: Checking The Fuel Injectors' Spray Pattern.

- TEST 2: Making Sure The Fuel Injectors Are Getting Power.

- TEST 3: Fuel Injector Resistance Test.

- TEST 4: Fuel Injector Activation Signal Test.

- TEST 5: Making Sure The Fuel Injector Is Getting Power.

- TEST 6: Making Sure The Fuel Injector Is Getting An Activation Signal.

- Tech Tip: Always Replace Injector O-Rings.

- More 3.9L V6 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 150 Pickup 3.9L V6: 1989, 1990, 1991.

- Dodge Ram 250 Pickup 3.9L V6: 1989, 1990, 1991.

FUEL INJECTOR WIRING DIAGRAMS:

- Fuel Injector Circuit Wiring Diagram (1989 3.9L V6 Dodge Ram Pickup).

- Fuel Injector Circuit Wiring Diagram (1990-1991 3.9L V6 Dodge Ram Pickup).

Symptoms Of A Bad Fuel Injector

The 1989–1991 3.9L V6 engines comes equipped with a Throttle Body Injection (TBI) system. This setup uses a twin-injector throttle body —each injector feeds fuel into its own throttle bore.

Here are the most common ways these injectors fail:

- Dead injector: One or both injectors stop working due to an internal problem and completely quit spraying fuel.

- Clogged injector: The injector still sprays, but not enough fuel gets through —or the spray pattern is uneven instead of the proper cone shape.

- Injector leaking fuel: After shutting off the engine, fuel should not drip out of the injector —but it does.

- Injector stuck open: The injector remains continuously energized from as soon as you turn the key and crank the engine, with no pulsing —just a constant ON state. This is often caused by a faulty fuel injection control module or a short-circuit in the injector wiring.

If one of these issues is going on, here's what you're gonna notice:

- Rough idle: The engine shakes while it's idling.

- Misfiring: You'll feel the engine stumble or hesitate, especially when you hit the gas.

- Lack of power: You may notice sluggish acceleration or reduced engine response when stepping on the gas.

- Bad gas mileage: Your pickup's fuel consumption was never great, but now it's thirstier than ever.

- No-start condition: If both injectors fail to spray, the engine won't fire up at all.

Where To Buy The Fuel Injector And Save

This is the TBI fuel injector that fits the 3.9L V6 Dodge Ram pickups:

Not sure if this fuel injector is the right one for your V6 Dodge Ram pickup? No problem —once you're on the site, they'll ask you to enter your vehicle's details to make sure it fits. If it's not a match, they'll help you find the correct part.

TEST 1: Checking The Fuel Injectors' Spray Pattern

First thing you'll want to do is take a look at the fuel injector spray pattern —either while you're cranking the engine (if it won't start) or with it running (if it fires up).

When everything's working right, both injectors should spray fuel in a nice cone shape —whether the engine's cranking or running.

While you're doing this check, keep an eye out for these common problems:

- No spray at all: One or both injectors aren't spraying any fuel whatsoever.

- Leaking fuel: You see fuel dripping from one or both injectors either when you turn the key to ON (before cranking), or after the engine shuts down.

- Fuel stream instead of a spray: Fuel is coming out, but instead of a fine mist, it's shooting out in a straight stream.

CAUTION: You're gonna have to crank the engine for this test, so be sure to be careful and take all necessary safety precautions.

Here's how to run the test:

- 1

Take off the air cleaner assembly from the throttle body.

- 2

Have someone crank the engine.

- 3

From a safe distance, watch both injectors to see how they spray.

NOTE: A small flashlight really helps here so you can clearly see how the fuel is being sprayed. - 4

You're looking for a cone-shaped spray from both injectors —and they should match.

Let's see what your test results are telling you:

CASE 1: Both fuel injectors are spraying in a conical pattern and stop when the engine is shut off. This is exactly what we want to see.

If the spray from both injectors looks the same and forms a proper cone, then you can be sure they're doing their job, and that:

- They're getting power from the ASD relay.

- The fuel injection computer is sending them their activation signals.

No need to dig any deeper here. If your engine's acting up or not starting, you can rule out the fuel injectors.

CASE 2: One fuel injector isn't spraying fuel. This will definitely mess with engine performance.

Next step is to check that injector's resistance. Go to: TEST 3: Fuel Injector Resistance Test.

CASE 3: Both fuel injectors aren't spraying fuel. That usually means they're not getting power or their activation signals.

For our next test, we need to make sure their receiving power. Head over to: TEST 2: Making Sure the Fuel Injectors Are Getting Power.

CASE 4: An injector is leaking from its nozzle or just squirting fuel instead of spraying it in a fine, conical pattern. This usually indicates an internal mechanical problem with that injector. Replace the fuel injector.

CASE 5: Fuel is leaking from around the injector —not from its nozzle. This generally tells you the injector's O-rings are no longer sealing the injector in its pod properly, allowing fuel to escape around the injector body.

Pull the injector, replace the O-rings with new ones, and repeat the test.

TEST 2: Making Sure The Fuel Injectors Are Getting Power

NOTE: Only run this test if both injectors aren't spraying and the engine won't start.

When you first turn the key to the ON position (without cranking the engine), the injectors get 12 Volts for about 3 seconds.

Once you start cranking the engine and the fuel injection computer sees the signal from the distributor pickup coil, the injectors (not to mention the ignition coil and fuel pump) get a steady 12 Volt supply.

This voltage comes from the Auto Shutdown (ASD) relay and reaches the fuel injectors through the dark green with black stripe (DK GRN/BLK) wire.

In the test we're about to do, we'll check for power in both situations: when the key is ON but the engine's off, and while the engine's actually cranking.

Alright, let's check for power:

- 1

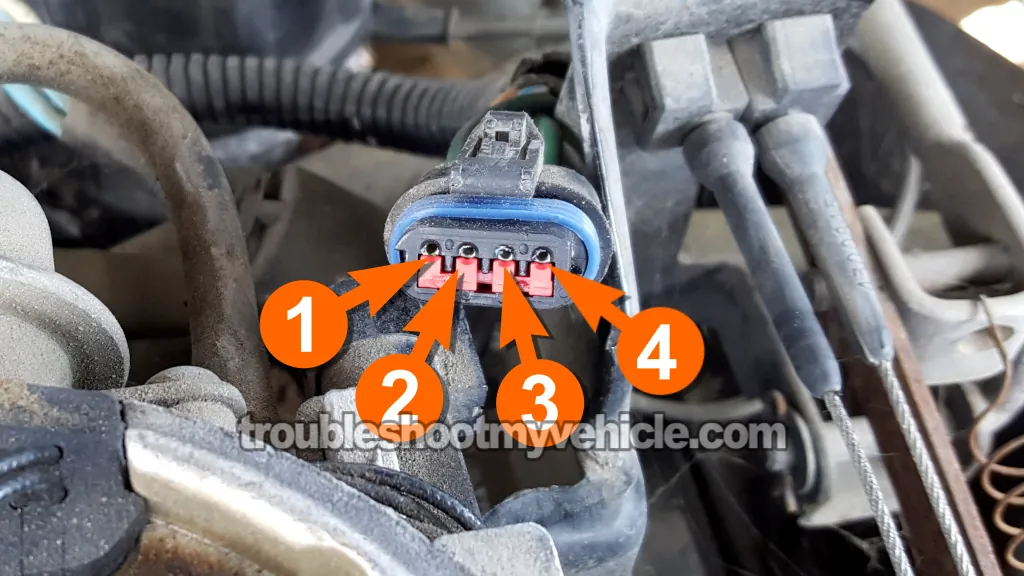

Unplug the 4-wire fuel injector connector. See photo 2 of 2 above to ID this connector.

- 2

Hook up the black multimeter lead to the negative (-) battery post.

- 3

Switch your multimeter to DC Volts mode.

- 4

Carefully probe terminal 1 on the 4-wire connector using the red multimeter lead.

Double-check that that terminal 1 connects to a dark green with black stripe (DK GRN/BLK) wire. - 5

Have your helper turn the key to ON, but don't crank the engine.

- 6

Your multimeter should read between 10 and 12 Volts for about 3 seconds.

We'll call this part of the test the key on engine off (KOEO) check.

The fuel injection computer will cut power after a few seconds if the engine doesn't crank —which is the normal behavior. - 7

Now have your helper crank the engine.

CAUTION: Stay alert and keep your hands, tools, and wires clear of anything that moves. - 8

During cranking, the multimeter should show a steady 10 to 12 Volts.

This is the key on engine running (KOER) portion of the test. - 9

Repeat both voltage checks on terminal 4.

NOTE: Make sure terminal 4 connects to the other DK GRN/BLK wire.

Let's break down what your results mean:

CASE 1: You're getting 10 to 12 Volts in both KOEO and KOER tests. That's exactly what you want to see.

This confirms the injectors are receiving power. This also confirms:

- That the fuel injection computer is getting a distributor pickup coil signal.

- The ASD is also sending power to the fuel pump and ignition coil.

Your next move is to check if they're also getting the activation signal. Head to: TEST 4: Fuel Injector Activation Signal Test.

CASE 2: You're NOT getting 10 to 12 Volts in either part of the test. No power means the injectors won't spray fuel. The most common reasons behind this is a bad Auto Shutdown (ASD) relay.

It's outside the scope of this tutorial, but the next thing you'll need to do is find out why this voltage is missing. Start with checking the ASD relay.

CASE 3: You see 10 to 12 Volts during KOEO but nothing during KOER. That's almost always a failed distributor pickup coil.

Here's why: when you first turn the key to ON, the computer activates the ASD relay. But if it doesn't see an engine-cranking signal from the pickup coil, it shuts that relay back off —cutting power to the injectors, ignition coil, and fuel pump.

If you're getting voltage with just the key ON, but not while cranking, it's a clear sign the fuel injection computer isn't seeing that pickup coil signal.

Your next step is to test the pickup coil. Use this guide: