TEST 6: Making Sure The Fuel Injector Is Getting An Activation Signal

NOTE: This part only applies if one of the injectors didn't spray fuel back in TEST 1.

If you've made it to this step, here's what you've already know:

- TEST 1: One injector is working; the other one isn't spraying.

- TEST 3: Both injectors show resistance within the correct range.

- TEST 5: The injector that isn't spraying is getting voltage.

In this step, we're gonna find out if that non-spraying injector is getting its activation signal —and we'll do it using a basic 12 Volt automotive LED light.

In my experience, an LED light is the safest way to do this. It protects the fuel injection computer's injector driver circuit from overload, and it makes it easy to spot those activation pulses.

If you don't have an LED light, you can see what one looks like and you can also buy it here: Oznium Flush Mount 12V LED Light (at: amazon.com).

NOTE: Don't use a regular 12V test light here. It can overload and possibly burn out the injector driver circuit inside the fuel injection computer.

Alright, let's get to it:

- 1

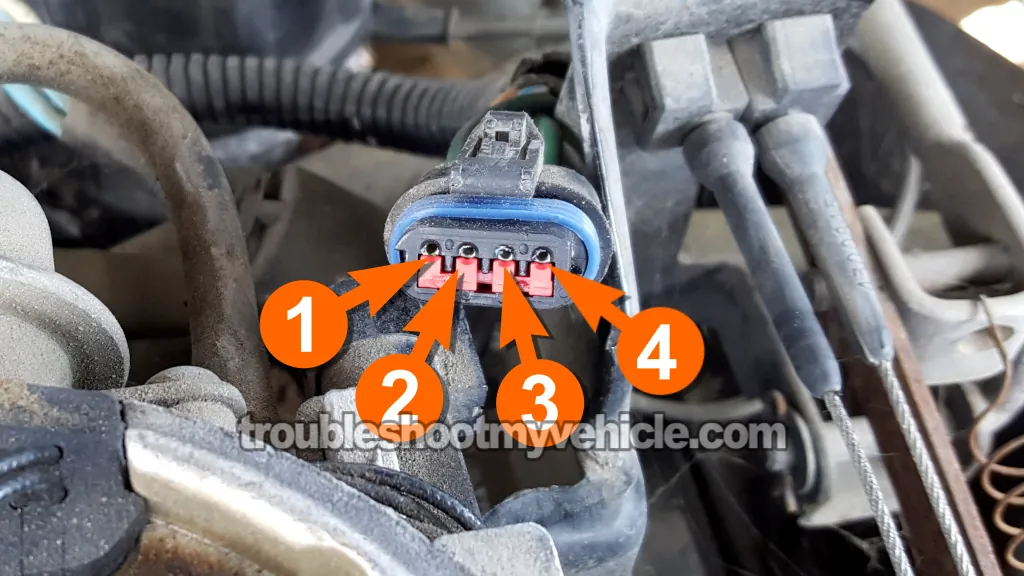

Unplug the 4-wire connector from the fuel injectors.

- 2

Connect the red lead from your LED test light to terminal 1 on the connector.

NOTE: Double-check that this terminal connects to a dark green with black stripe (DK GRN/BLK) wire. - 3

Connect the black lead of the LED to terminal 2.

Terminal 2 should be wired to the tan (TAN) wire —this one supplies the activation signal to injector #2. - 4

Have your helper crank the engine.

CAUTION: Stay alert and keep your hands and tools away from any moving parts. - 5

The LED should blink ON and OFF steadily as the engine cranks.

- 6

Now move the red lead of the LED to terminal 3.

- 7

Terminal 3 connects to the white with dark blue stripe (WHT/DK BLU) wire. This wire supplies the activation signal for injector #1.

- 8

Again, have your helper crank the engine.

CAUTION: Just like before, be careful around moving parts. - 9

The LED should blink ON and OFF while the engine is cranking.

Here's how to break down the results:

CASE 1: The LED blinked ON and OFF for both terminals. That's the expected result —it shows that the computer is sending the signals to fire both injectors.

If you've already confirmed all of the following:

- The injector isn't spraying fuel (TEST 1).

- Both injectors have correct resistance (TEST 3).

- The non-working injector is getting power (TEST 5).

- And now, both injectors are getting activation signals (this test).

Then that non-spraying injector is the problem —go ahead and replace it.

CASE 2: The LED didn't flash on one of the signal wires. That means that injector isn't getting the pulse it needs to fire.

If you know it's getting power (from TEST 5), then there's probably a break in the activation wire between the injector and the fuel injection computer.

Next, you'll want to check continuity between the injector connector and the computer's connector. If that wire's open, fixing it should get the injector firing again.

Tech Tip: Always Replace Injector O-Rings

If you're planning to pull out one or both fuel injectors —whether you're swapping them for testing or replacing them outright— it's really important that you don't reuse the old O-rings.

Here's why that matters: O-rings are what create the tight, leak-proof seal between the injector and the throttle body pod. But once you remove an injector, those rings can get nicked, stretched, or slightly deformed —even if they still look fine.

Reusing them might seem like no big deal, but it seriously raises your chances of a fuel leak after the engine's shut off.

To stay on the safe side, here's what you need to do:

- Use brand-new O-rings made specifically for your engine and fuel injectors.

- Apply a light coat of petroleum jelly to the new O-rings so they slide in easier and don't get torn during install.

It's just a couple of extra minutes, but doing this can save you a major hassle later on.

More 3.9L V6 Dodge Ram Pickup Tutorials

You can find a complete list of diagnostic tutorials for the full-size Dodge Ram pickups in this index:

Here's a sample of the tutorials you'll find in the old index:

- How To Test The Ignition Coil (1989-1991 3.9L V6 Dodge Ram Pickup).

- How To Test The Distributor Pickup Coil (1989-1991 3.9L V6 Dodge Ram Pickup).

- Throttle Body Temp Sensor Tests (1989-1991 3.9L V6 Dodge Ram Pickup).

- How To Test For A Blown Head Gasket (1989-2001 3.9L V6 Dodge Ram Pickup).

If this info saved the day, buy me a beer!