TEST 7: Activation Signal For Cylinders 2 And 3

So far, you've checked and confirmed:

- TEST 1 —Cylinders 2 and 3 spark plug wires didn't spark.

- TEST 4 —Cylinders 2 and 3 coil pack towers didn't spark either.

We now need to check if Ignition Coil B is receiving its activation signal to fire spark to its paired cylinders (2 & 3).

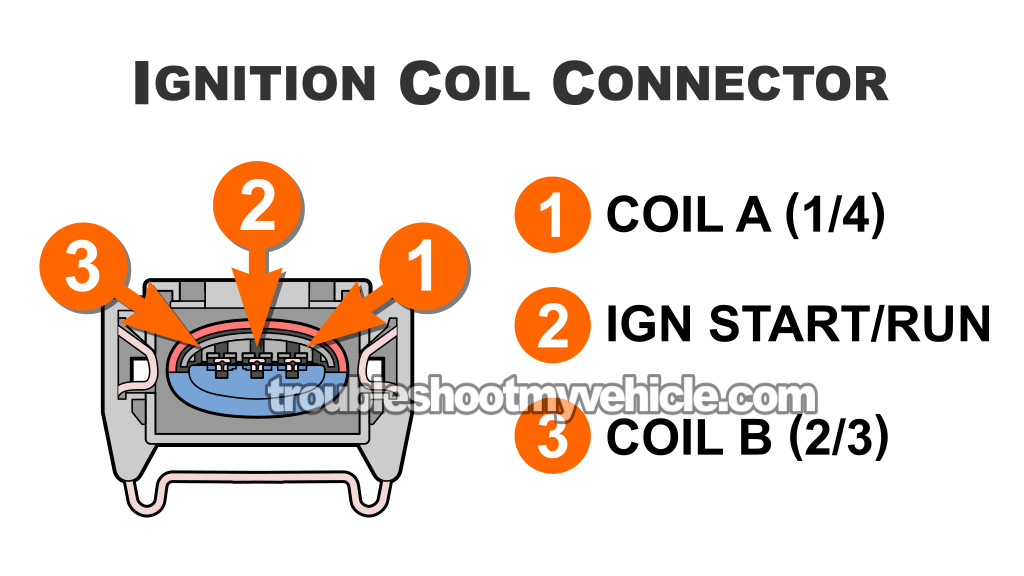

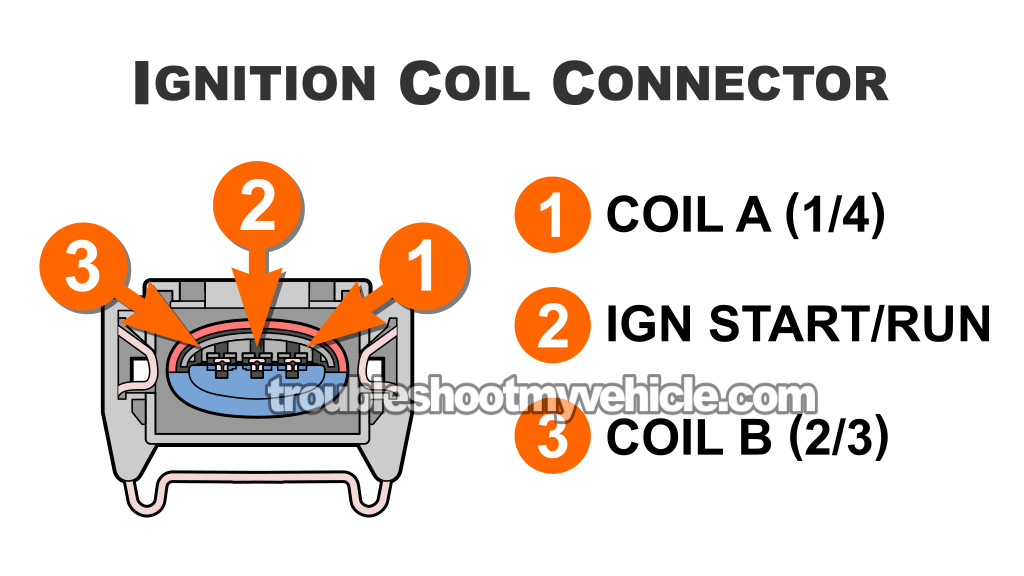

The Coil B control signal is supplied by your Focus's PCM and is delivered to terminal 3 of the coil pack's 3-wire connector.

To check for this signal at terminal 3, we'll use a standard automotive 12V incandescent test light.

NOTE: Use a regular 12-Volt test light with an incandescent bulb to check for the coil's activation signal. If you don't have one, this is the one I recommend —you can buy it here: Lisle 28400 Heavy Duty 12 Volt Test Light (Amazon affiliate link).

Alright, let's get to it:

- 1

Disconnect the ignition coil pack's 3-wire connector.

- 2

Clip the alligator lead of your 12V test light to the battery negative (-) post.

- 3

Probe female terminal 3 of the coil pack connector with the tip of the test light.

Confirm that terminal 3 actually connects to the black with green stripe (BLK/GRN) wire of the connector.

NOTE: Be careful not to damage the female terminal with the probe —if you do, you'll have to replace the connector. - 4

Have your helper crank the engine.

- 5

The 12V test light should flash ON and OFF the whole time the engine cranks.

NOTE: Don't worry about what the test light does before cranking the engine —whether it comes on or not. What matters is that it flashes while the engine is cranking.

OK, let's interpret your test result:

CASE 1: The test light flashed ON and OFF. This is the correct test result and it confirms your Focus's PCM is sending the Coil B activation signal.

The coil pack is bad and needs to be replaced, if you've confirmed all of the following:

- Spark plug wires for cylinders 2 & 3 are not sparking (TEST 1).

- Coil towers for cylinders 2 & 3 are not sparking (TEST 3).

- Coil B activation signal is present at terminal 3.

Ready to swap out the coil pack? Here are two brands I've relied on since I first started wrenching on cars —Standard Motor Products and Motorcraft:

- Standard Motor Products FD497T Ignition Coil (Amazon affiliate link).

- Motorcraft - IGN Coil DG536 (Amazon affiliate link).

CASE 2: The test light DID NOT flash ON and OFF. This means Coil B isn't receiving its activation signal from the PCM, which is why the spark plug wires and coil pack towers for cylinders 1 & 4 aren't sparking.

Your next step is to troubleshoot the missing Coil B activation signal and restore it to the circuit. Most likely, the Coil B signal wire has an open-circuit problem between the PCM and the coil pack connector.

TEST 8: Checking Coil A And B Activation Signals

Your previous two tests have confirmed:

- TEST 1 —All four spark plug wires aren't sparking.

- TEST 4 —The coil pack is receiving IGN power.

Our final check is to see if the PCM is sending both ignition coil activation signals to the coil pack.

The two signals we need to verify are:

- Coil A activation signal (cylinders 1 & 4).

- Coil B activation signal (cylinders 2 & 3).

To check for these two control signals, we'll use a standard automotive 12V incandescent test light.

NOTE: To run this test, you'll need a standard 12-Volt test light with an incandescent bulb. If you don't already have one, this is the one I use and recommend: Lisle 28400 Heavy Duty 12 Volt Test Light (Amazon affiliate link).

These are the test steps:

- 1

Disconnect the coil pack's 3-wire connector.

- 2

Clip the alligator lead of your 12V test light to the battery negative (-) post.

- 3

Test terminal 1 (ignition coil A).

Probe female terminal 1 of the connector with the tip of the test light.

Verify that terminal 1 connects to the black with orange stripe (BLK/ORG) wire.

NOTE: Be careful not to damage the female terminal with the probe —if you do, you'll have to replace the connector. - 4

Have your helper crank the engine. The test light should flash ON and OFF the whole time the engine cranks.

- 5

Test terminal 3 (ignition coil B).

Move the probe to female terminal 3 of the connector.

Verify that terminal 3 connects to the black with green stripe (BLK/GRN) wire. - 6

Have your helper crank the engine again. The test light should flash ON and OFF the whole time the engine cranks.

Let's find out what your test result means:

CASE 1: The test light flashed ON and OFF at both terminals. This test result confirms both coil A and coil B activation signals are present.

The coil pack is bad and needs to be replaced if you have checked and confirmed:

- None of the spark plug wires are sparking (TEST 1).

- The coil pack is getting IGN power (TEST 4).

- It's getting both Coil A and Coil B activation signals.

Ready to buy a new coil pack? I want to recommend one from either Standard Motor Products and Motorcraft, both are reliable brands with a solid track record:

- Standard Motor Products FD497T Ignition Coil (Amazon affiliate link).

- Motorcraft - IGN Coil DG536 (Amazon affiliate link).

CASE 2: The test light DID NOT flash ON and OFF at both terminals. This is telling you the coil pack isn't receiving either activation signal, and this is the reason we didn't see spark in all four spark plug wires in TEST 1.

With this result, we can rule out the coil pack as bad since without these signals, it's not gonna generate spark.

Your next step is to troubleshoot why both signals are missing. The most likely reason for these missing activation signals is a bad crankshaft position (CKP) sensor.

Other Things That Can Cause A Misfire

If all four cylinders have spark and the ignition components (wires, coil pack, spark plugs) are OK and doing their job, then the cause of the cylinder misfire lies elsewhere.

In this section, I'll cover some other issues you'll need to check to help you pinpoint the true cause of your Ford Focus's rough idle or misfire.

-

Engine oil in the spark plug wells (DOHC engine) —A very common issue with the 2.0L DOHC engine is oil leaking into the spark plug tube wells. The end result is spark plugs and spark plug wire boots swimming in oil. Over time, that oil cooks (carbonizes) and forms carbon tracks on the spark plug's porcelain insulator and on the inside the spark plug wire boot (see the photo above).

Those carbon tracks eventually cause the spark to arc to Ground instead of going through the spark plug, leading to a cylinder misfire. Carbon tracks can't be cleaned off completely, so if you see the plugs and wire boots covered in engine oil, you'll need to replace them. Here's a case study on this type of problem:

-

Low or uneven engine compression —Engine compression issues in one or more cylinders will cause a cylinder misfire. This is especially true in high-mileage engines. So if you haven't checked compression yet, it should definitely be on your list. The following tutorial explains in detail how to do and interpret a compression test:

-

Clogged or failed fuel injectors —A clogged fuel injector will cause a cylinder misfire since it can't inject the right amount of fuel or atomize it into a proper mist.

Another common issue is an injector that's suffered an internal short-circuit or open-circuit failure. In that case, it won't inject any fuel at all.

The good news is the injectors on both the DOHC and SOHC engines are pretty accessible, so testing them isn't too difficult. If you've confirmed that the misfiring cylinder is getting spark and has good compression, your next step is to check the injector's internal resistance with a multimeter —and possibly remove and clean it with a DIY toolkit.

-

Intake manifold gasket leaks —The intake manifold gasket is another very common failure point that can cause a rough idle or a cylinder misfire, especially when the engine is cold.

- On the DOHC engine, the intake manifold gaskets are rubber. Over time, they harden, shrink, and stop sealing.

- On the SOHC engine, the intake manifold-to-cylinder head gasket is a composite plastic gasket with rubber seals. Eventually, it disintegrates and creates vacuum leaks that cause a rough idle or cylinder misfire.

There are several ways to check for intake manifold gasket leaks. My favorite DIY approach is spraying brake clean or carb clean around the gasket area and watching for a change in engine idle RPM.

If you haven't checked for vacuum leaks around the intake manifold-to-cylinder head gasket area, make sure you do —especially if compression and ignition system tests look good.

More 2.0L Ford Focus Diagnostic Tutorials

You can find a complete list of tutorials and wiring diagrams for the 2.0L Ford Focus in this index:

Here's a small sample of the tutorials you'll find:

- How To Test The MAF Sensor (2000-2004 2.0L Ford Focus).

- How To Test The Throttle Position Sensor (2000-2004 2.0L SOHC Ford Focus).

- How To Test For A Blown Head Gasket (2000-2010 2.0L Ford Focus).

- How To Test Engine Compression (2000-2010 2.0L Ford Focus).

If this info saved the day, buy me a beer!