TEST 2: Checking The Condition Of The ECT Sensor's 2 Wires

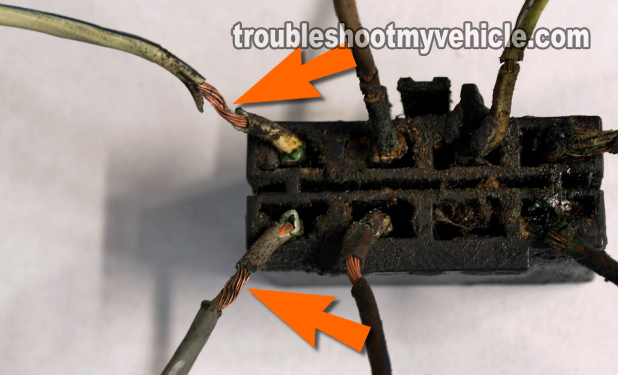

In some cases, the PCM registers a P0118 ECT Sensor Circuit High Voltage Input because 1 of the 2 ECT sensor's circuits (wires) has an open-circuit problem.

In plain English this means that one or both wires are cut and not letting the power voltage signal or the Ground signal thru'. Usually, it's the sensor's connector that has broken and is making a false contact.

NOTE: You don't have to check the entire length of the wiring between the PCM and ECT sensor connector, just the length nearest to the ECT sensor's connector (about 6 inches away from ECT sensor's connector).

OK, this is what you need to do:

- 1

Remove the hard plastic protector that's over the wires.

You need to expose the ECT sensor's wires starting from the connector to about 6 inches away (from the connector). - 2

Check for dry-rot and/or insulation peeling off the 2 ECT sensor wires.

The most likely place you'll find this condition (dry-rot and/or insulation peeling off) is right near the ECT sensor's connector. - 3

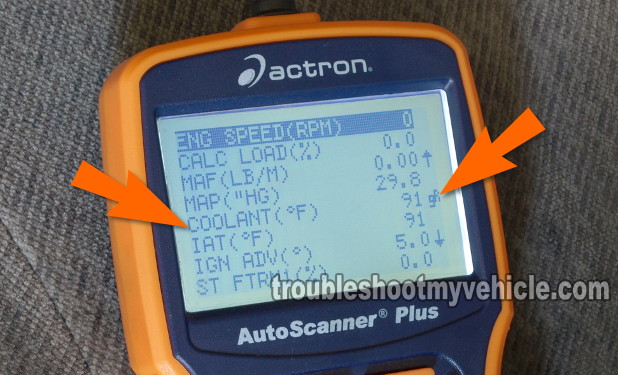

Have a helper wiggle the 2 ECT sensor wires while you observe the ECT sensor's PID labeled COOLANT (on your scan tool).

What you're looking for is to see if wiggling the wires has any effect on the temperature reported on your scan tool.

Let's interpret your test results:

CASE 1: The wires have dry-rot and/or insulation peeling off and/or are cut. This condition is the most likely cause of code P0118. You need to replace the engine coolant sensor's connector or repair/replace the affected wires.

CASE 2: Wiggling the 2 ECT sensor wires caused a change in the temperature reading. This test result tells you that the wires do have a problem.

You need to carefully inspect the connector and the 2 wires and replace and/or repairing what's damaged or shorted.

To give you some more specifics: Gently wiggling the ECT sensor connector's 2 wires should have no effect on the ECT sensor reading displayed on the scan tool, unless the connector is bad or one of the wires has an open-circuit problem. Since wiggling the connector did have an effect, you now know that replacing the ECT sensor connector or repairing the problem in the wires will solve the ECT sensor and P0118 Code problem.

CASE 3: The wires DO NOT HAVE dry-rot and ARE NOT shorted together and wiggling the ECT sensor connector's wires DID NOT cause the temperature to change. This tells you that the ECT sensor connector and its wires are OK.

In most cases, this test result also tells you that the ECT sensor is the one that's malfunctioned and needs to be replaced. Before you do, I suggest one more test.

And this is to test to make sure that the PCM is not fried. This is a very simple test and it requires that you disconnect the ECT sensor from its connector and then checking, with your scan tool in Live Data mode, that the engine coolant temperature (ECT) sensor's PID is now reading -4 °F (-20°C).

For this test, go to: TEST 3: Jumpering Together the ECT Sensor Circuits.

TEST 3: Jumpering Together The ECT Sensor Circuits

In this test step, we're gonna' eliminate two specific possibilities that can cause a P0118 ECT Sensor Circuit High Voltage Input trouble code.

One is a bad PCM that's falsely accusing the ECT sensor as having failed. Although having a PCM go bad is very rare, it does happen and we need to eliminate this possibility.

Second, a hidden electrical short in the wires between the PCM and ECT sensor, that could fool the PCM into thinking the ECT sensor is bad.

We can eliminate these two possibilities by jumpering the ECT sensor's 2 wires together and then, via the scan tool in Live Date mode, see if the COOLANT PID now shows an extreme hot temperature of 300°F (150°C).

If your scan tool now registers this extreme hot temperature, you now know that the PCM is OK and there are no hidden electrical shorts in the wiring between it and the ECT sensor.

OK, here's what you'll need to do:

- 1

Check the current COOLANT value on your scan tool's display.

- 2

Disconnect the ECT sensor from its connector and using a jumper wire jumper the two metal terminals.

IMPORTANT: Be careful and don't insert a jumper wire that will damage the connector's terminals or you'll cause a false contact that'll require a new connector. - 3

PID COOLANT should now read 300°F (150°C) for the engine coolant temperature (ECT) sensor reading after you've jumpered the 2 circuits.

- You'll also see DTC P0117.

Let's take a look at what your test results mean:

CASE 1: The PID labeled COOLANT registered 300°F (150°C). This test result tells you that the wiring between the PCM and ECT sensor connector is OK and that the PCM is not fried.

You have now confirmed 3 very important things:

- That the PCM is seeing an extreme hot temperature around 300 °F (TEST 1).

- That there are no shorts in the sensor's wiring or in its connector (TEST 2).

- That the PCM is OK (TEST 3).

Therefore, you can confidently conclude that the ECT sensor is bad and needs to be replaced.

CASE 2: The PID labeled COOLANT DID NOT register 300°F (150°C). Make sure that you're testing the correct wires, that your connections are OK, and repeat the test.

Then this tells you that you have a problem in the wiring between the ECT sensor and the PCM or that the PCM is fried (although a bad PCM is rare).

Although testing the wiring between the PCM and the ECT sensor is beyond the scope of this tutorial, you now have eliminated the ECT sensor as the source of the P0118.