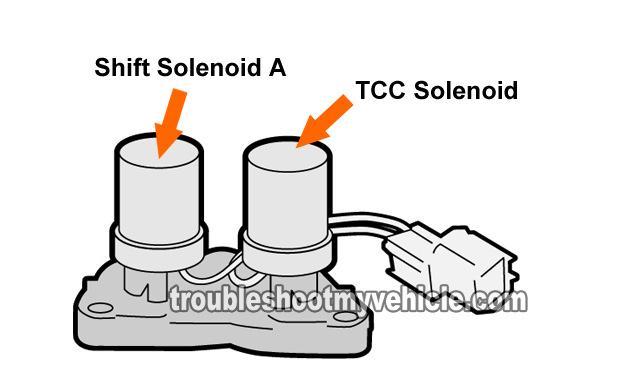

TEST 1: Shift Solenoid A Resistance Test

In this first test, we're gonna' measure the shift solenoid's internal resistance and see if it's within specification.

If it isn't within specification, then you've confirmed that shift solenoid is bad and also the cause of the P0735 DTC.

NOTE: Perform this test with a completely cold engine/transmission to avoid getting your hands burned.

OK, this is what you need to do:

- 1

Place your multimeter in Ohms mode.

- 2

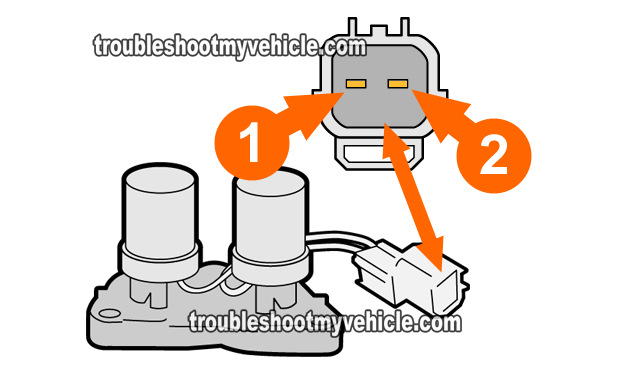

Unplug the lock up solenoid assembly from its electrical connector.

NOTE: This test is done on the lock-up solenoid's connector AND NOT on the engine wiring harness' pigtail connector. - 3

Measure the resistance between terminal labeled with the #2, in the image viewer above, and the solenoid assembly's body.

NOTE: Shift solenoid A is Grounded by the solenoid assembly's case. If the solenoid assembly is still bolted to the transmission housing, you can Ground your multimeter's lead directly on the battery's negative (-) terminal. - 4

Your multimeter should read 12-25 Ohms for the resistance value of shift solenoid A.

Let's take a look at what your test results mean:

CASE 1: Resistance was between 12-25 Ohms. This is the correct and expected test result and generally means that shift solenoid A is OK.

Although the shift solenoid A passed this test, there's still one more we need to do, which is to manually apply power to the solenoid and see if it clicks. Go to: TEST 2: Applying 12 V To Shift Solenoid A.

CASE 2: Resistance WAS NOT between 12-25 Ohms. Recheck your multimeter test connections and retest. If you still don't get the correct resistance, then shift solenoid A is bad and needs to be replaced.

TEST 2: Applying 12 V To Shift Solenoid A

There's a good chance that shift solenoid A passed TEST 1 with flying colors yet a trouble code P0735 continues to light the D4 light and/or check engine light on the instrument cluster.

So the next step, after measuring shift solenoid A's internal resistance, is to manually apply 12 Volts to terminal #2 and see if the solenoid clicks.

IMPORTANT: If you've removed the solenoid assembly to test it, you'll need to do one of two things: Bolt it back in place (on the transmission's case). Or Ground the solenoid assembly to the engine (or battery negative post) with a battery jump cable (or this test won't work).

These are the test steps:

- 1

Unplug the lock up solenoid assembly from its electrical connector.

NOTE: This test is done on the lock-up solenoid's connector AND NOT on the engine wiring harness' pigtail connector. - 2

Apply 12 Volts to terminal #2, of the lock-up solenoid assembly's connector, using a jumper wire or a power probe.

- 3

You should hear an audible click when the 12 Volts are applied.

Repeat this test as many times as you need to be certain of your test results.

Let's examine your test results:

CASE 1: An audible click was heard when applying 12 Volts. This test result tells you that the solenoid is opening and closing but (there's always a but) this doesn't mean the solenoid is good.

There's a chance that the solenoid is bad, even though it passed TEST 1 and this one (TEST 2). I have some suggestions that may help. For more details, go to: The Lock-up Solenoid Assembly Tested Good But Still Not Shifting.

CASE 2: An audible click WAS NOT heard when applying 12 Volts. This test result tells you that shift solenoid A is bad and needs to be replaced.

Since shift solenoid A is part of the lock-up solenoid assembly, you'll need to replace the entire assembly to solve the issue.