The compression test is one of those go-to tests when it comes to figuring out the internal health of your 1993–1998 Nissan Quest's 3.0L V6 engine.

In this tutorial, I'm going to explain how the test is done and, more importantly, how to interpret your test results to find out if you've got a cylinder causing a rough idle condition or a cylinder misfire.

The compression test will also let you know if you've got a compression problem that's keeping the engine from starting.

All of the test steps are explained in a step-by-step manner so you can quickly and easily figure out what's going on.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Nissan Quest: 1993, 1994, 1995, 1996, 1997, 1998.

- 3.0L V6 Mercury Villager: 1993, 1994, 1995, 1996, 1997, 1998.

CYLINDER MISFIRE DIAGNOSTICS:

Symptoms Of Low Or No Engine Compression

As you're probably already aware, each cylinder in your Nissan Quest 3.0L V6 engine needs three things to be able to produce power: you need fuel, you need spark, and you need compression.

So when there's a compression problem in any of the six cylinders, you're going to run into an engine performance issue. Engine compression problems usually fall into two specific categories:

- You've got one or more (but not all) cylinders with low or no compression.

- No compression in all six cylinders.

Here are some more specifics about the above two conditions.

One or more (but not all) cylinders have low or no compression: This is probably the most common issue you're going to see, especially on these high-mileage engines, where you'll usually have a cylinder or two with worn-out piston rings or worn-out cylinder head valves. And when that happens, you're going to see one or more of the following symptoms:

- Misfire codes (if the vehicle is OBD II equipped) lighting up the check engine light:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

- P0305: Cylinder #5 Misfire.

- P0306: Cylinder #6 Misfire.

- Engine misses at idle.

- Lack of power.

- Blue smoke coming out of the tailpipe at idle and/or when accelerating (this is engine oil burning in the cylinders).

No compression in all 6 cylinders: When all six cylinders show zero compression, the engine won't start —and most of the time this points to a broken timing belt. In more severe cases, it can mean the engine has thrown a rod. Any time you've got no compression in all six cylinders, you're going to see one or more of the following:

- The engine cranks very fast and this fast cranking speed is very noticeable.

- The ignition system is not creating spark (only occurs if timing belt is broken).

- Fuel pump is working and providing pressure.

Which Compression Tester Should I Buy?

If you don't have an engine compression tester —or maybe you need to upgrade the one you've got— these are the ones I recommend. They're reliable and not expensive:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Dry Engine Compression Test

Alright, we're going to begin by checking the compression on all six cylinders. You don't absolutely have to test all six, but for the most accurate results, I recommend that you do.

If you decide to test only one cylinder —for example, the one you've already identified as misfiring— you'll still need to test at least two more.

Those two additional readings —along with the "dead" cylinder's reading— give you the comparison data you need to calculate whether that cylinder's compression is actually within a normal range or not.

IMPORTANT: You'll be working around a cranking engine, so you have to be careful and stay alert at all times. Think safety all of the time!

This is what you'll need to do:

- 1

Disconnect the distributor from its electrical connector. This is just to make sure that the ignition coil does not fire off spark during the compression testing of the cylinders.

- 2

Remove all 6 spark plugs. As your taking them out, be careful and don't drop any of them on the floor, or you could cause the spark plug's ceramic insulator to break, and this will cause a misfire!

IMPORTANT: You should label each spark plug wire with its location before you remove the spark plugs so that you can connect them (the spark plug wires) back to the correct spark plug once you're done with the compression test. - 3

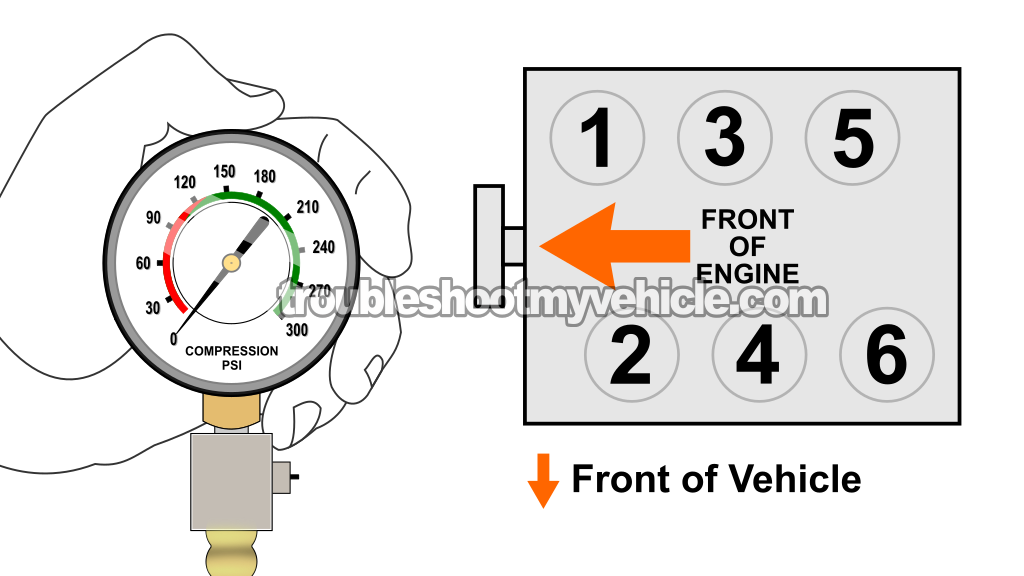

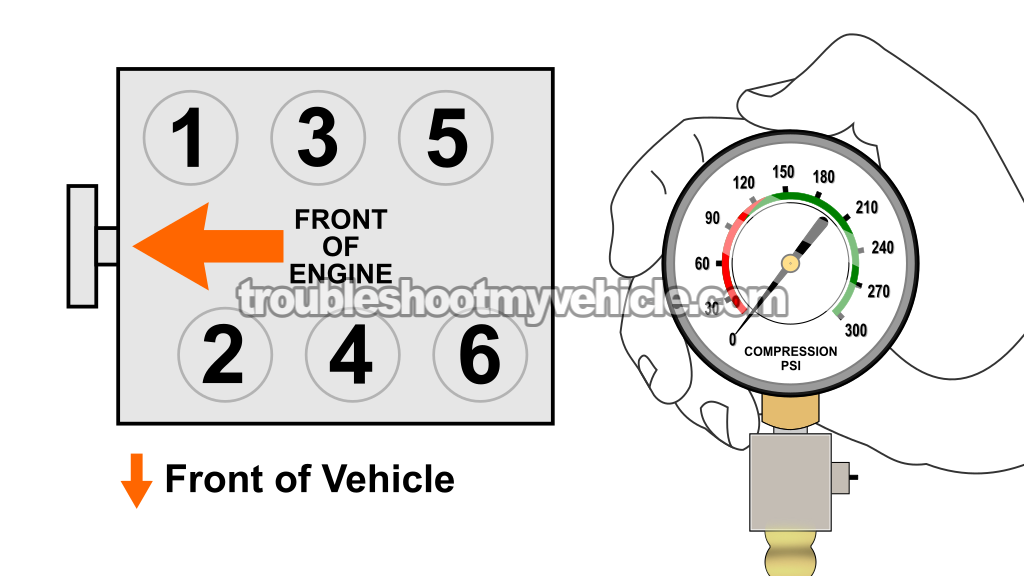

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder.

Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 4

Have a helper crank the engine, when the test is set up, as you observe the needle on the compression tester's gauge.

- 5

Once the needle on the gauge stops climbing, have him or her stop cranking the engine.

- 6

Write down the compression test result and the cylinder the test result belongs to.

- 7

Repeat the test in the other 5 cylinders.

OK, let's see what it all means:

CASE 1: You got low or no compression in two side-by-side cylinders. This test result lets you know that you probably have a blown head gasket, and that the gasket has failed right between those two adjacent cylinders —causing the zero PSI compression in both.

CASE 2: No compression in all six cylinders. This zero-PSI result across all six cylinders will definitely cause the engine not to start.

The most common cause of this issue is a broken timing belt on your 3.0L V6 Nissan Quest. Your next step is to check the condition of the timing belt.

The other (less common) possibility is that the engine threw a rod.

CASE 3: You've got one or two cylinders (not side-by-side) with low or no compression. On a high-mileage engine, having a cylinder with low compression is kinda common.

The next step is to find out whether that low compression value is still within an acceptable range —and we can do a little math to figure that out. Head over to: Interpreting Your Compression Test Results.

Interpreting Your Compression Test Results

The 3.0L V6 in your 1993-1998 Nissan Quest has quite a few years on it, so it's completely normal to find a cylinder or two showing lower compression than the others. The key is knowing how low it can go before it starts creating engine performance problems.

The general rule of thumb is this: the lowest compression reading should not be more than 15% lower than the highest reading. If the difference is greater than 15%, you're going to run into engine performance issues —usually a rough idle or a cylinder misfire.

There are two easy ways to check this: you can calculate that 15% difference by hand, or you can use my low-compression calculator. You'll find the calculator here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that I got the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

| #5 | 160 PSI |

| #6 | 165 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: 'Wet' Engine Compression Test.

TEST 2: Wet Engine Compression Test

If you find that you have a cylinder with a low compression value that isn't within the acceptable range —or you've got a cylinder with zero PSI compression— the next step is to figure out whether that issue is being caused by worn-out piston rings or a problem with the cylinder's intake or exhaust valves.

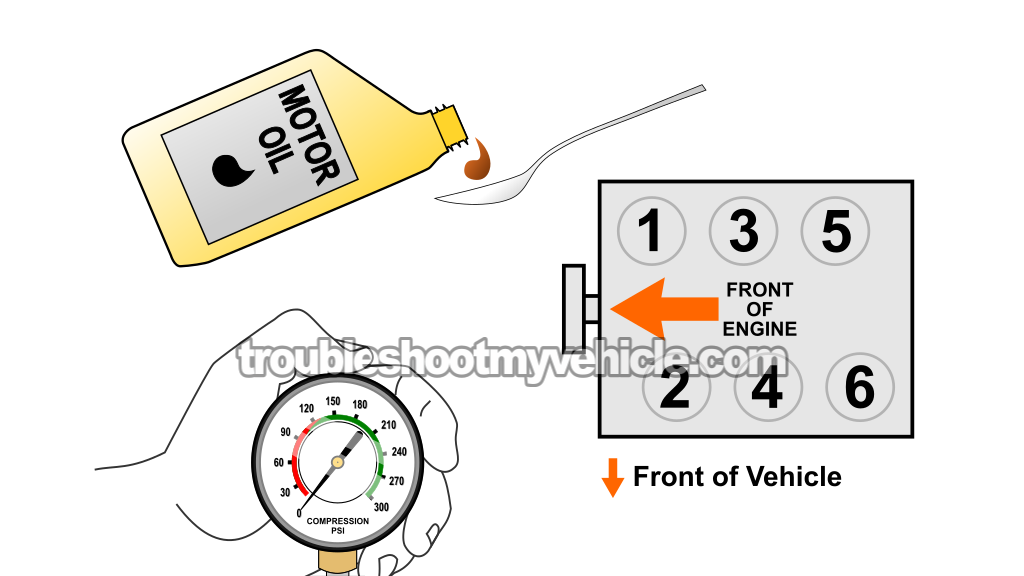

We can easily do this by adding a small amount of engine oil (usually about two tablespoons) to that cylinder and checking its compression again. You're going to see one of two things:

- Compression value shoots up: This test result lets you know that the low or zero PSI compression issue is being caused by worn-out piston rings.

- Compression value does not change: With this result, you can conclude that the issue is being caused by the cylinder's intake or exhaust valves —they're either excessively worn or damaged.

Alright, here are the test steps to perform the wet compression test.

- 1

Add a small amount of engine oil to the cylinder that reported low compression or no compression in the 'dry' compression test.

The amount should be about 1 to 2 tablespoons of oil. - 2

Install the compression tester onto the cylinder. Do not use any type of tool to tightened the compression tester. Hand tight is fine.

- 3

Crank the engine after you've set up the test.

- 4

You'll get one of two results:

1.) The compression value will go up (from the one you recorded before).

2.) The compression value will stay the same.

Let's analyze your wet compression test results:

CASE 1: The cylinder's compression value shot up. This confirms that the low compression value you saw in TEST 1 is being caused by worn-out piston rings.

CASE 2: The cylinder's compression value did not change. This test result lets you know that the compression issue is being caused by worn or damaged intake or exhaust valves in that cylinder.

More 3.0L V6 Nissan Quest Diagnostic Tutorials

You can find a complete list of tutorials and wiring diagrams for the 3.0L Nissan Quest in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Camshaft Position Sensor (1993-1998 3.0L V6 Nissan Quest).

- How To Test The Ignition Coil And Power Transistor (1993-1998 3.0L V6 Nissan Quest).

- Common Causes Of Spark Plug Failure (1993-1998 3.0L V6 Nissan Quest).

- How To Test For A Blown Head Gasket (1993-1998 3.0L V6 Nissan Quest).

If this info saved the day, buy me a beer!