Testing the fuel injectors on a 1997-2001 2.2L Toyota Camry for internal short-circuit or open-circuit issues is a pretty straightforward process with a multimeter.

The test isn't complicated, and I'll walk you through it step by step. Plus, I'll share a sure-fire diagnostic strategy to help you pinpoint a bad or clogged fuel injector with confidence.

Contents of this tutorial:

- Symptoms Of A Bad Fuel Injector.

- START HERE: How To Find The Bad Or Clogged Fuel Injector.

- TEST 1: Checking The Resistance Of The Fuel Injectors.

- TEST 2: Checking If The Fuel Injector Sprays Fuel.

- Important Precautions To Take When Installing A Fuel Injector.

- Important Precautions To Take When Installing The Valve Cover.

- More 2.2L Toyota Camry Test Tutorials.

APPLIES TO: This tutorial applies to the following gasoline powered vehicles:

- 2.2L Toyota Camry: 1997, 1998, 1999, 2000, 2001.

Wiring Diagrams:

- Fuel Injectors Circuit Wiring Diagram (1997 2.2L Toyota Camry).

- Fuel Injectors Circuit Wiring Diagram (1998-1999 2.2L Toyota Camry).

- Fuel Injectors Circuit Wiring Diagram (2000-2001 2.2L Toyota Camry).

1992-1996 Fuel Injector Tests:

Symptoms Of A Bad Fuel Injector

Fuel injectors, unfortunately, can fail in two main ways, and each type of failure affects engine performance:

- Internal electrical issues: A short-circuit or open-circuit prevents the injector from spraying fuel into its cylinder.

- Clogged injector: Debris, carbon buildup, or fuel contaminants block the nozzle, restricting fuel flow.

When a fuel injector fails, you'll notice one or more engine performance issues, such as:

- Rough idle: Uneven combustion caused by a clogged or non-spraying injector leads to the engine shaking or vibrating while idling.

- Lack of power: Insufficient fuel delivery from a clogged or non-spraying injector causes the engine to feel sluggish and underpowered, especially during acceleration.

- Engine hesitation under load: Inconsistent fuel flow from a clogged injector makes the engine stutter or jerk during acceleration.

- Cylinder misfire trouble codes:

- P0300: Random Cylinder Misfire.

- P0301: Misfire In Cylinder #1.

- P0302: Misfire In Cylinder #2.

- P0303: Misfire In Cylinder #3.

- P0304: Misfire In Cylinder #4.

Whether a fuel injector has an internal electrical issue or is clogged, this tutorial will help you find out.

START HERE: How To Find The Bad Or Clogged Fuel Injector

I've been using a methodical diagnostic testing strategy for years to pinpoint the exact cause of a cylinder misfire—whether it's due to a bad fuel injector, a clogged injector, or something entirely different.

When troubleshooting a misfire, it's easy to waste time and money replacing parts that aren't the root cause. To avoid that, I follow a step-by-step elimination process to rule out each possible culprit. Here's what you'll need to do:

- Identify the "dead" cylinder first:

- The success of the entire diagnostic strategy depends on identifying the "dead" cylinder. This can be done one of two ways:

- Perform a manual cylinder balance test to isolate the misfiring cylinder.

- Use an automotive scan tool or code reader to identify misfire codes (e.g., P0301 for Cylinder #1).

- The success of the entire diagnostic strategy depends on identifying the "dead" cylinder. This can be done one of two ways:

- Verify that the "dead" cylinder's spark plug wire fires spark:

- Ensure the "dead" cylinder's spark plug wire is delivering spark to it.

- Inspect spark plugs and spark plug wire boots for cracks or carbon tracks:

- Look for cracks, wear, or carbon tracks on the spark plugs, which can cause misfires.

- Look for engine oil contamination on the spark plug wire boots and spark plugs, which can cause misfires.

- For more info: Carbon Tracks Are A Common Cause Of Ignition Misfires (at: easyautodiagnostics.com).

- Check the "dead" cylinder's compression:

- Perform an engine compression test on the dead cylinder to rule out mechanical issues like damaged piston rings or valves.

- How To Test Engine Compression (1990-2001 2.2L Toyota Camry, Celica).

- Test the "dead" cylinder's fuel injector activation signal:

- Use a Noid light to confirm the injector is receiving the proper activation signal from the ECU.

- How To Use A Noid Light And Where To Buy It (at: easyautodiagnostics.com).

- Check the internal resistance of the "dead" cylinder's fuel injector:

- Use a multimeter to measure the injector's internal resistance and compare it to the manufacturer's specs (I'll explain how in this tutorial).

- Visually inspect the fuel injector's fuel spray pattern:

- Remove the injector and observe whether it's spraying fuel correctly and atomizing properly during operation (I'll explain how in this tutorial).

- Swap the "dead" cylinder's injector with an adjacent one:

- Swap the suspect injector with one from a nearby cylinder. If the misfire follows the injector, you've confirmed it's either clogged or faulty.

This step-by-step elimination process ensures you don't overlook any potential cause of the misfire. By systematically testing each component, you'll pinpoint the exact issue without wasting time or money on unnecessary replacements.

TEST 1: Checking The Resistance Of The Fuel Injectors

IMPORTANT: This test and TEST 2 only apply to gasoline powered 2.2L Toyota Camrys.

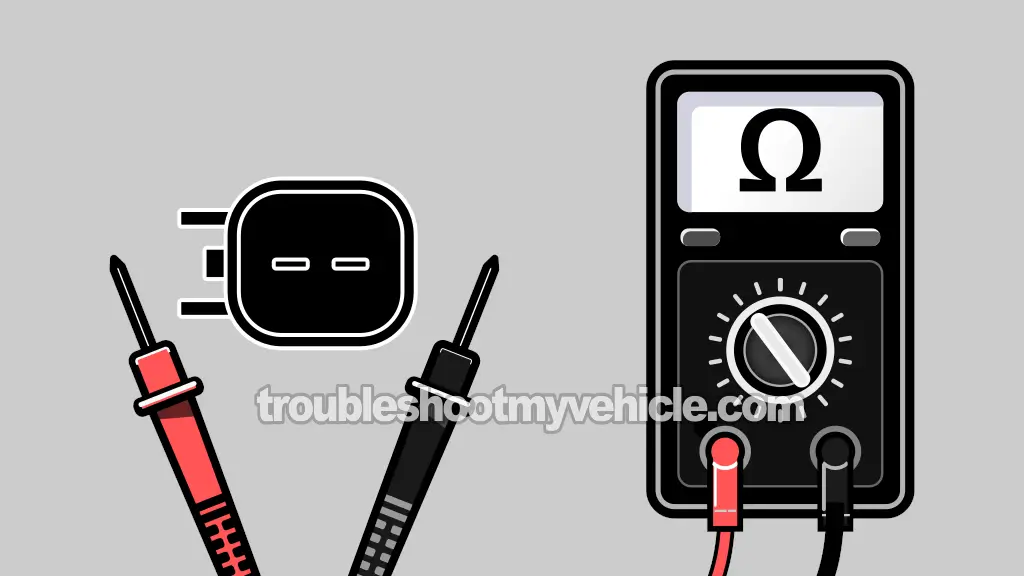

To diagnose a fuel injector issue on your Toyota Camry, we'll measure the internal resistance of each injector using a multimeter. With this test, we'll quickly identify if an injector has an internal electrical fault preventing it from spraying fuel.

Each fuel injector in your 1997-2001 Toyota Camry should have a standard resistance of around 13.4 to 14.20 Ohms (as per the factory specs). The goal here is simple: look for an injector whose reading stands out from the others.

If a problem is detected, it'll typically fall into one of these three scenarios:

- Short-circuit: The resistance reads below 1 Ohm, indicating an internal short-circuit in the injector's coil windings.

- Open-circuit: The resistance shows a high value in the thousands (K) of Ohms, suggesting a break in the internal circuit.

- Deviation from standard: The resistance differs by 10 Ohms or more from the expected 13.4 to 14.20 Ohms, signaling excessive wear or internal damage to the injector.

By systematically comparing the resistance values of all four fuel injectors, you'll quickly spot the bad one —no guessing, no wasting money on parts that won't fix the problem.

Let's get started:

- 1

Disconnect the fuel injectors from their electrical connectors.

NOTE: This test is done with the engine OFF. - 2

Set the multimeter to Ohms (Ω) mode.

- 3

Measure the fuel injector's resistance across its two male terminals with the multimeter probes (see the illustration above).

- 4

Record the resistance value that your multimeter shows for the specific fuel injector you're testing.

NOTE: Cylinder #1 is the one closest to the drive belt. Cylinder #4 is the one closest to the transmission. - 5

Repeat steps 1 to 3 for the remaining fuel injectors.

Let's interpret your test results:

CASE 1: All four injectors show similar resistance values. There are no short-circuit or open-circuit issues with any of them.

Keep in mind, a resistance test won't detect a clogged injector. The next step is to remove the "dead" cylinder's fuel injector and check that it's spraying fuel. Go to: TEST 2: Checking If The Fuel Injector Sprays Fuel.

CASE 2: One injector's resistance significantly deviates (by 10 Ohms or more) from the others. This tells you that the fuel injector is bad and should be replaced.