TEST 2: Checking If The Fuel Injector Sprays Fuel

IMPORTANT: Take a look at the following two sections before you start your fuel injector spray test:

- Important Precautions To Take When Installing A Fuel Injector.

- Important Precautions To Take When Installing The Valve Cover.

A fuel injector might pass an electrical resistance test (no short-circuit or open-circuit issues) but still fail to inject fuel correctly —or at all. To ensure the injector is working properly, we need to make sure it can spray fuel correctly.

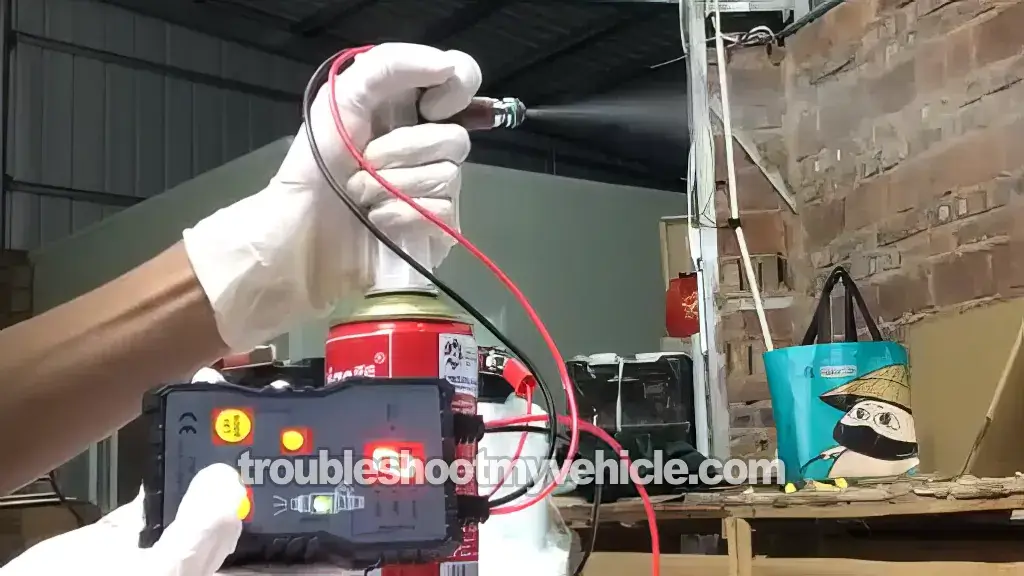

To test this, we'll use a special tool that sends electrical pulses to the injector. Here's how the test works:

- Connect the fuel injector to the special test tool's power module (this modules supplies the injector with power and an activation signal).

- Attach the injector to a spray can of brake cleaner using an adapter.

- Activate the test tool to pulse the injector, allowing brake cleaner to flow through it.

When the injector activates, you'll see one of two outcomes:

- A fine, conical spray of brake cleaner comes out: This means the injector is working correctly and atomizing fuel properly. (Good news!)

- A small squirt or no spray at all: This means the injector is clogged and isn't delivering fuel as it should.

I've used this game-changing tool several times, and honestly, I wish it had been around 30 years ago!

You can see it and buy it here:

When testing a fuel injector's spray pattern using brake cleaner, safety comes first. Brake cleaner is highly flammable, and its vapors can be hazardous. Follow these precautions to keep yourself and your workspace safe:

- Work in a well-ventilated area or outdoors: Prevent brake cleaner vapors from building up in an enclosed space.

- Stay away from open flames, sparks, and heat sources: Even a tiny spark can ignite brake cleaner vapors.

- Wear safety goggles and gloves: Protect your eyes and skin from accidental splashes.

- Keep a fire extinguisher nearby: Better to have it and not need it than the other way around.

- Spray away from yourself and others: Always direct the spray away from your face and body, and ensure nothing flammable is nearby.

These safety precautions might seem like a hassle, but trust me —they're non-negotiable when working with flammable materials under pressure.

Important Precautions To Take When Installing A Fuel Injector

When you need to remove and reinstall the same or a new fuel injector, there's a super important rule to follow:

- Never reuse the old fuel injector O-rings.

O-rings are rubber seals that create a tight, fuel-proof seal between the injector and the fuel rail. When you remove a fuel injector, its O-ring gets stretched, compressed, or even slightly damaged —even if it looks fine.

Reusing old O-rings is asking (begging) for trouble. It can result in:

- Fuel leaking onto the engine.

- Increased risk of an engine fire.

Before reinstalling the new O-ring:

- Always use new O-rings specifically designed for your Camry's fuel injector(s).

- Lightly lubricate the new O-rings with clean engine oil before installation. This helps them seat properly and prevents pinching or tearing during reassembly.

It's a small but crucial step since replacing O-rings takes just a few minutes, but it can save you from a lot of trouble (and potentially expensive repairs) in the long run!

I like to remind myself that new O-rings are cheap compared to the potential damage an engine fire could cause. So, always take the extra minute to use new O-rings when reinstalling a fuel injector.

Important Precautions To Take When Installing The Valve Cover

In this section, I'll walk you through the important steps and precautions you need to follow when removing and reinstalling the valve cover (to access the fuel injectors to remove them), inspecting spark plug wires, and replacing spark plugs.

These suggestions aren't just about getting the job done —they're about avoiding new headaches to deal with down the road.

Valve cover:

- When removing the valve cover (to access the fuel injectors):

- Be extra careful not to let dirt, debris, or tools fall into the exposed cylinder head once the valve cover is off.

- When installing the valve cover:

- Install the valve cover with a new gasket and spark plug tube seals.

- The valve cover gasket and spark plug tube seals must be installed clean and dry —no sealer or RTV silicone should be used on them.

- The only spot where you'll need a small dab of RTV silicone is where the camshaft caps meet the cylinder head (see the photo above).

Spark plugs and spark plug wires:

- Check spark plug wire boots for oil contamination:

- If the spark plug wire boots are covered in engine oil, it's a sign that the spark plug tube seals on the valve cover are leaking oil into the spark plug tubes.

- My recommendation: Replace the spark plug wires with new ones.

- Cleaning the boots usually doesn't cut it.

- Carbon tracks can't be cleaned off. Once oil gets between the boot and spark plug, it carbonizes and creates a pathway for electricity to short out, leading to cylinder misfire issues.

- Oil-contaminated spark plug boots will cause misfires —no question about it.

- Check the spark plugs:

- If the boots are covered in engine oil, the spark plugs are likely also coated or swimming in oil.

- The spark plugs must be removed and replaced (if soaked in engine oil).

- Oil on the spark plug porcelain insulator often cooks and forms carbon tracks. These carbon tracks will lead to a cylinder misfire problem. For more info on this, see this article:

- Carbon Tracks Are A Common Cause Of Ignition Misfires (at: easyautodiagnostics.com).

- If replacing spark plugs:

- Check the electrode gap: Even if the packaging says they're pre-gapped, double-check the gap to ensure it matches the manufacturer's specifications. The only exception is multiple-electrode spark plugs—they don't need gapping.

- Use a torque wrench: Tighten the spark plugs to the correct torque specification.

Following these steps will help you prevent future issues and ensure your repair is done right the first time. I've learned the hard way that cutting corners here almost always leads to headaches later on, so take your time and do it by the book.

More 2.2L Toyota Camry Test Tutorials

If this tutorial was helpful, be sure and take a look at all of the 2.2L Toyota Camry diagnostic tutorials in this index:

Here's a sample of the tutorials you'll find there:

- How To Test The Alternator (1992-2001 2.2L Toyota Camry).

- How To Test The Thermostat (1992-2001 2.2L Toyota Camry).

- How To Test The Igniter (1992-1995 2.2L Toyota Camry).

- How To Test The Fuel Pump (1992-1995 2.2L Toyota Camry).

- How To Test For A Blown Head Gasket (1990-2001 2.2L Toyota Camry, Celica).

If this info saved the day, buy me a beer!