In this tutorial, I'm gonna show you two tests you can perform on the CMP sensor to find out if it's good or if it has failed (and needs to be replaced).

The best part? You don't need any fancy diagnostic tools for these tests —just a basic multimeter that can measure Ohms and AC voltage. No scan tool required!

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Toyota Camry: 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

Ignition System Tests:

- How To Test The Ignition Coils (1994-1995 3.0L V6 Toyota Camry).

- How To Test The Ignition Coils (1996-2001 3.0L V6 Toyota Camry).

- How To Test The Crankshaft Position (CKP) Sensor (1994-2006 3.0L V6 Toyota Camry.

Wiring Diagrams:

- Ignition System Wiring Diagram (1994 3.0L V6 Toyota Camry).

- Ignition System Wiring Diagram (1995 3.0L V6 Toyota Camry).

- Ignition System Wiring Diagram (1996 3.0L V6 Toyota Camry).

- Ignition System Wiring Diagram (1997-1998 3.0L V6 Toyota Camry).

- Ignition System Wiring Diagram (1999-2001 3.0L V6 Toyota Camry).

Engine No-Start Diagnostics:

Camshaft Position (CMP) Sensor Basics

The camshaft position (CMP) sensor in the 1994-2003 3.0L V6 Toyota Camry is a variable reluctance sensor, thus its 2-wire connector. These 2-wire sensors are also known as magnetic reluctance sensors.

You'll find the CMP sensor mounted on the front cylinder head, on the side facing the radiator (see the photo at the start of this tutorial).

Here's a breakdown of how the CMP sensor works as crank and start the engine:

- The camshaft begins rotating.

- The CMP sensor detects the reluctor teeth passing by and produces an alternating current (AC) voltage signal.

- This AC signal, along with the CKP sensor's output, is sent to the fuel injection computer.

- The computer uses both signals to determine which cylinder is nearing top dead center (TDC) on its compression stroke.

- With this information, the computer enables ignition timing and fuel injection, allowing the engine to start and run.

Unlike 3-wire Hall-effect sensors, which need an external power supply and output a digital square wave signal, variable reluctance sensors like the CMP sensor generate their own AC voltage signal in a sine wave pattern. No external power source is required.

As a variable reluctance sensor, the CMP sensor's signal frequency and amplitude change with engine speed. This makes it super important to test the sensor's output with a completely charged battery so that you can obtain the fastest possible cranking speed.

Symptoms Of A Bad CMP Sensor

When the camshaft position (CMP) sensor on your 1994-2003 3.0L V6 Toyota Camry goes bad, the most common issue you're gonna see is:

- Engine no-start: If the CMP sensor completely fails and stops generating a signal, the engine will crank but won't start.

Other signs of a failing CMP sensor include:

- Check engine light: A faulty CMP sensor usually triggers the check engine light and sets a diagnostic trouble code (DTC).

- Engine stalling: If the CMP sensor cuts out intermittently, it can cause the engine to stall unexpectedly, whether you're driving or the engine is just idling.

- Engine misfires or rough idle: Inaccurate signals from the CMP sensor can throw off ignition timing, leading to misfires or a rough-running engine.

I do want to point out that these symptoms can also be caused by other problems. That's why testing the CMP sensor's resistance and output before replacing it is the way to go to avoid wasting time and and money on parts that aren't gonna solve the issue.

Where To Buy The CMP Sensor And Save

The following links will help you comparison shop for the CMP sensor of two well known automotive brands (Dorman and Delphi):

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

NOTE: Not sure if the CMP sensor fits your particular 3.0L V6 Toyota Camry? Don't worry. Once you get to the site, they'll ask you for the specifics of your vehicle. If it doesn't fit, they'll find you the right one.

TEST 1: Measuring The Resistance Of The CMP Sensor

The most common failure in a CMP sensor is an internal open-circuit or short-circuit problem.

The first test we'll perform on the CMP sensor is to measure its internal resistance using a multimeter set to Ohms mode.

This super simple resistance test will quickly reveal if the sensor has an internal short-circuit or open-circuit issue.

These are the resistance values we can expect if the CMP sensor is OK:

- Cold: 835 to 1400 Ohms.

- Hot: 1,060 to 1645 Ohms.

NOTE: If you don't have a multimeter, check this one out (it's the one I use): Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter with NCV Feature (at: amazon.com).

Let's get testing:

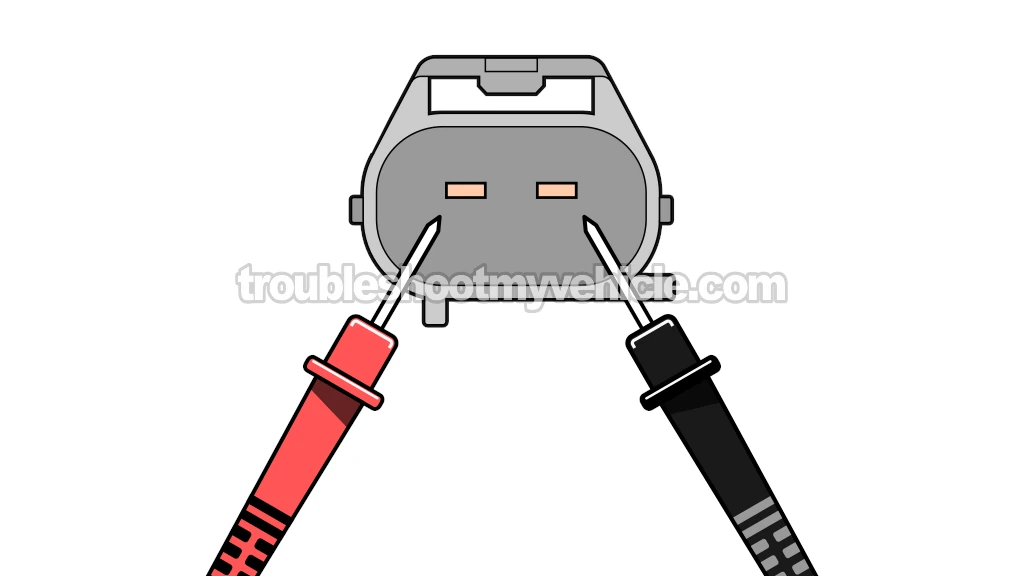

- 1

Disconnect the CMP sensor from its engine wiring harness connector.

- 2

Set your multimeter to Ohms mode.

- 3

Probe the resistance across the male spade terminals with the multimeter test leads.

- 4

The multimeter should register an Ohms value in the indicated range.

Cold: 835 to 1400 Ohms.

Hot: 1,060 to 1645 Ohms.

Let's interpret your test result:

CASE 1: The multimeter registered the indicated Ohms value. This is the correct and expected test result.

Your next step is to test the CMP sensor in action. Go to TEST 2: Testing The CMP Sensor With The Engine Cranking.

CASE 2: The multimeter registered no continuity (infinite resistance). This tells you that the CMP sensor is bad (it has an internal open-circuit problem).

Replace the camshaft position sensor.

CASE 3: The multimeter registered 0 resistance. This indicates the CMP sensor has suffered a short-circuit problem. It needs to be replaced.

TEST 2: Testing The CMP Sensor With The Engine Cranking

As I mentioned earlier, the CMP produces an AC voltage signal when you crank the engine (and when it's running).

We can easily check that the CMP sensor is actually generating this AC voltage signal with a multimeter (set to Volts AC mode) while we crank the engine.

This is what our multimeter should report:

- Good CMP sensor: The multimeter will register an AC voltage reading of around 0.4–1.2 Volts AC while cranking.

- Bad CMP sensor: The multimeter will show zero AC Volts during cranking.

NOTE: The easiest way to connect the multimeter to the CMP sensor terminals is with jumper wires that have insulated alligator clips. You can see an example of this type of jumper wire (and you can buy them too) here: 10 Pc. And 5 Color Insulated Alligator Clips (at: amazon.com).

NOTE: For the most accurate results, make sure your Toyota Camry's battery is fully charged before running this test.

These are the test steps:

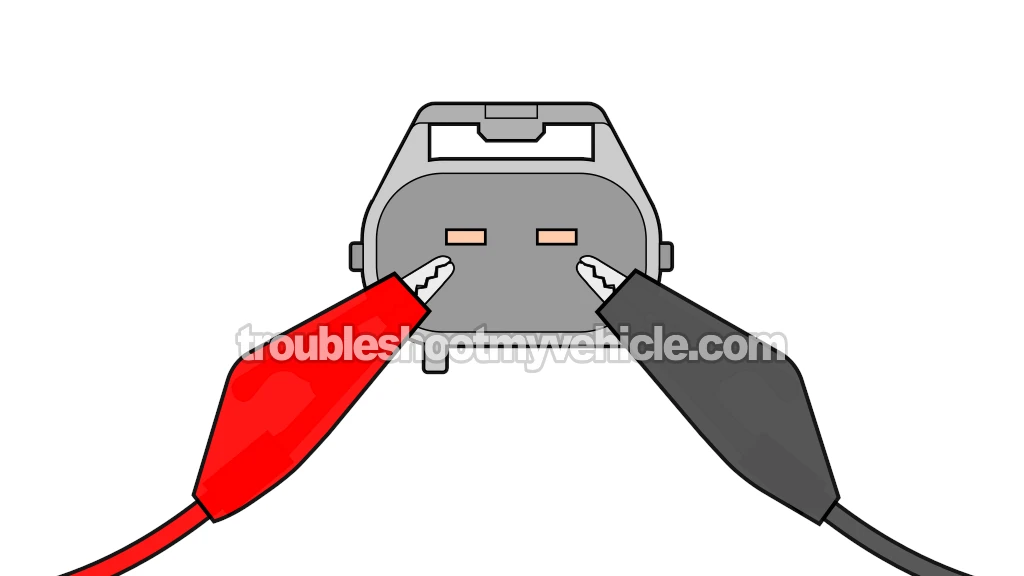

- 1

Disconnect the ignition coils from their electrical connectors.

NOTE: This is a safety precaution to keep the engine from starting during the CMP sensor test. - 2

Disconnect the CMP sensor from its electrical connector.

- 3

Place your multimeter in Volts AC mode.

- 4

Connect the multimeter test leads to the male spade terminals of the CMP sensor's connector with jumper wires with insulated alligator clips.

IMPORTANT: You're probing the male spade terminals of the CMP sensor itself and not the female terminals of the engine wiring harness connector. - 5

Have a helper crank the engine as you observe the multimeter.

CAUTION: Be careful and stay alert as the engine is cranking. - 6

The multimeter should report an AC voltage that will oscillate somewhere around 0.4 to 1.2 Volts AC.

CASE 1: The multimeter reported the indicated AC voltage. This test result confirms that the CMP sensor is functioning correctly.

CASE 2: The multimeter reported 0 AC voltage. This test result confirms that the CMP sensor is bad and needs replacement.

More 3.0L Toyota Camry Tutorials

You can find a complete list of 3.0L Toyota Camry tutorials in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test Engine Compression (1992-2006 3.0L V6 Toyota Camry).

- How To Test For A Blown Head Gasket (1992-2006 3.0L V6 Toyota Camry).

- How To Test The TPS (1997-2001 3.0L V6 Toyota Camry).

- How To Test The MAF Sensor (1997-2001 3.0L V6 Toyota Camry).

If this info saved the day, buy me a beer!