In this tutorial, I'll show you how to test the distributor pickup coil on the 1992–1993 3.0L V6 Toyota Camry.

I'll cover what the pickup coil does, common symptoms of a faulty one, and step-by-step instructions for testing it with a multimeter.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Toyota Camry: 1992, 1993.

- 3.0L V6 Lexus ES300: 1992, 1993.

Ignition System Tests:

- Engine No-Start Ignition System Tests (1992-1993 3.0L V6 Toyota Camry).

- How To Test The Igniter (1992-1993 3.0L V6 Toyota Camry).

Wiring Diagram:

Engine No-Start Diagnostics:

What Does The Distributor Pickup Coil Do?

The distributor pickup coil plays a crucial role in the engine's operation by providing important engine speed and piston position data to the fuel injection computer.

It generates three primary signals —NE, G1, and G2— as analog AC voltage signals, which the computer uses to accurately determine RPM and piston position. Additionally, there's a G- signal that serves as a Ground reference for these signals.

Here's what each signal does:

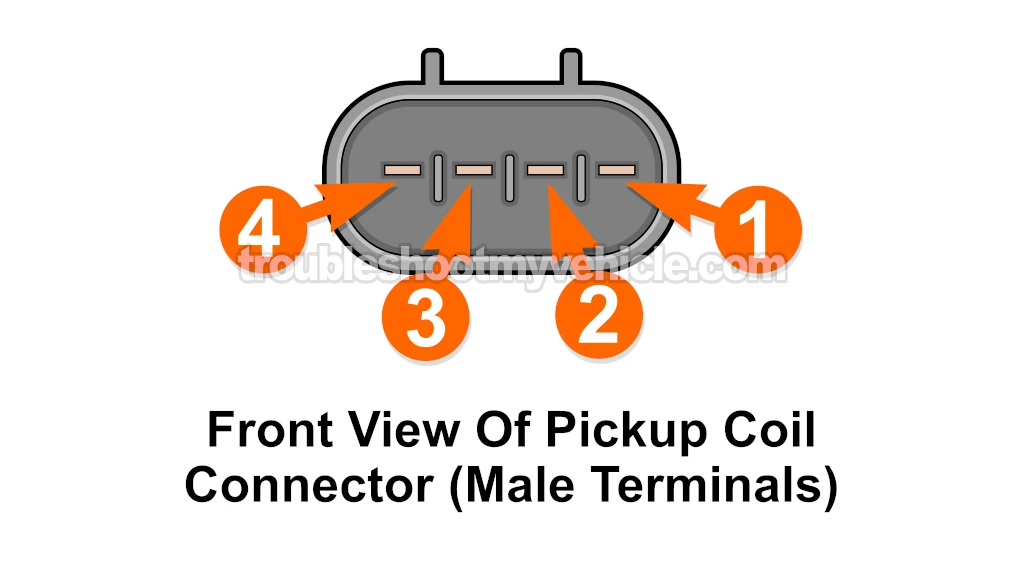

- Terminal 1 - NE: This is the engine speed (or crankshaft position) signal. The NE signal is what the computer uses to figure out engine RPM.

- Terminal 2 - G1: This is one of the cam angle reference (camshaft position) signals. It helps the computer figure out which cylinder is nearing its TDC position.

- Terminal 3 - G2: This is the second cam angle reference (camshaft position) signal. It does basically the same job as G1 but for another reference point on the cam.

- Terminal 4 - G-: This is the Ground reference for the NE and G signals (G1 and G2). It completes the circuit for the crankshaft and camshaft angle signals. This Ground is provided internally by the fuel injection computer.

Symptoms Of A Bad Distributor Pickup Coil

A bad distributor pickup coil can cause a range of issues, including:

- Engine no-start: If the pickup coil is not functioning properly, it's not gonna send the necessary signals the fuel injection computer needs to start activating the ignition coil and the fuel injectors.

- Engine misfires or stumbling: When the distributor pickup coil is faulty, it may cause misfires or stumbling. Engine stumble refers to a phenomenon where the engine's combustion process becomes irregular or unstable, often resulting in a sudden loss of power or hesitation while driving or while the engine idles.

- Engine stalls (turns off) unexpectedly: If the pickup coil is not generating the correct signals, it can disrupt the fuel injection computer's ability to maintain a steady idle or running condition. As a result, the engine may suddenly shut off, often without warning.

- Rough idle or hesitation: When the distributor pickup coil is malfunctioning, it can cause the engine to run rough or hesitate under load. This might manifest as a stumbling or stuttering sensation when accelerating or decelerating.

- Difficulty starting the engine: If the pickup coil is not functioning properly, it may take multiple attempts to get the engine started, and even then, it might not run well.

Important Safety Precautions

The following precautions will help to significantly reduce the risks involved in testing the distributor pickup coil while cranking the engine:

- Disconnect the ignition system: Disconnect the ignition coil from its electrical connector to disable the ignition system to prevent the engine from starting while cranking.

- Perform the tests on a cold engine: If the engine has been running, allow it to cool down before beginning your tests to avoid burns from hot engine components. In most cases, the distributor pickup coil is being tested because the engine won't start. However, if the engine starts and runs fine, the pickup coil is functioning correctly, and further testing isn't necessary.

- Ensure the battery is fully charged: A fully charged battery is essential for maintaining the highest possible engine cranking speed. Since the ignition coil is disconnected, the engine is not gonna start and it relies entirely on battery power to crank, and low cranking speed can affect test accuracy.

- Be cautious around moving parts: Keep hands, tools, and body parts away from belts and pulleys while the engine is cranking. Remove any loose clothing or dangling items from your person that could get caught in moving engine parts.

- Double-check connections: Make sure your multimeter probes are connected to the correct pins or wires.

- Have an assistant (if possible): Having someone else crank the engine while you monitor the multimeter can help reduce risk and make the process smoother.

TEST 1: Making Sure The Pickup Coil Is Getting Ground

For our first test, we're gonna make sure that distributor pickup coil is getting Ground from the fuel injection computer.

This Ground is shared by all three sensors (NE, G1, and G2) that make up the pickup coil. Without it, each sensor will not generate a signal.

The wire that delivers this Ground from the fuel injection computer, is the yellow (YEL) wire of the distributor's 4-wire connector.

These are the test steps:

- 1

Set your multimeter to Volts DC.

- 2

Disconnect the distributor from its 4-wire connector.

- 3

Connect the black multimeter lead to the battery negative (-) post.

- 4

Turn the key to the ON position.

- 5

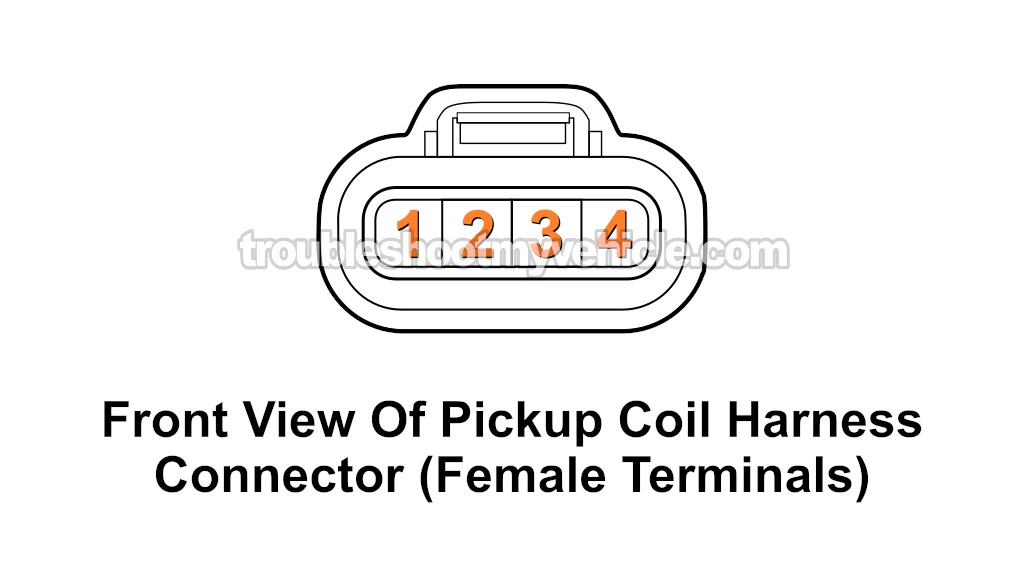

With the red multimeter, probe female terminal number 4 of the distributor's 4-wire connector.

Verify that female terminal number 4 corresponds to the YEL wire.

NOTE: This test is done on the distributor's engine wiring harness connector. This connector has female terminals. - 6

Your multimeter should read 10 to 12 Volts DC, if Ground is present.

Let's interpret your test result:

CASE 1: Ground is present. This is the correct and expected test result.

You're next step is to verify the NE signal (as the engine is cranked). Go to: TEST 2: Testing The NE Signal.

CASE 2: Ground IS NOT present. Without Ground, the distributor pickup coil will not function.

The most likely cause of this missing Ground is an open-circuit problem between the distributor's 4-wire connector and the fuel injection computer's connector.

Although it's beyond the scope of this tutorial, your next step is to troubleshoot and resolve the issue causing the lack of this Ground in the YEL wire.

TEST 2: Testing The NE Signal

For our second test, we're gonna check that distributor pickup coil is generating the NE signal.

It's important that you perform this test and the other two with a completely charged battery, since you want to be able to have the engine cranking at its fastest possible speed.

NOTE: The distributor must remain connected to its 4-wire connector to read the pickup coil signals. You'll need to access the NE, G1, and G2 signals using a back-probe (on the connector) or a wire-piercing probe (on the wire itself). You can check out an example (and where to buy it) here: Wire Piercing Probe.

Let's begin:

- 1

Disconnect the ignition coil from its 2-wire connector.

NOTE: This is a safety precaution that will prevent the engine from starting. - 2

Set your multimeter to Volts AC mode.

- 3

Connect the black multimeter test lead to the battery negative (-) terminal.

- 4

Connect the red multimeter test lead to the black (BLK) wire of the distributor's 4-wire connector.

The BLK wire should correspond to female terminal 1 of the illustration above.

NOTE: The distributor must remain connected to its 4-wire connector to read the NE signal. - 5

Crank the engine while you observe the multimeter from a safe distance.

- 6

The NE signal should be around 1.0-2.0 Volts AC as the engine cranks.

NOTE: If the NE coil is OK, its output voltage is going to fluctuate. You mainly want to see that you're getting a readable AC voltage (as the engine cranks) rather than an exact "2 Volts AC" number. If the AC voltage is 0, the NE coil is not generating a signal.

Let's interpret your test result:

CASE 1: The multimeter registered the indicated AC Voltage. This is the correct and expected test result and confirms that the NE signal generating portion of the pickup coil is OK.

Your next step is to check the presence of the G1 signal. Go to: TEST 3: Testing The G2 Signal.

CASE 2: The multimeter registered 0 AC Voltage. This lets you know that the NE signal generating portion of the pickup coil is defective. Replace the distributor pickup coil.

NOTE: The pickup coil isn't sold separately -you'll need to purchase a new distributor).