In this tutorial, I'll explain how to test the igniter (ignition control module) on the 1992-1993 3.0L V6 Toyota Camry.

This is an on-car test of the igniter -no need to remove it to test it. All of the test steps are explained in a step-by-step manner so that you can easily and quickly diagnose the igniter as good or bad.

Contents of this tutorial:

- Symptoms Of A Bad Igniter.

- Igniter Circuit Descriptions.

- Basic Operation Theory Of The Igniter.

- TEST 1: Making Sure The Igniter Is Getting Power.

- TEST 2: Making Sure The Igniter Is Getting Ground.

- TEST 3: Testing The Igniter Control Signal.

- TEST 4: Testing The Ignition Coil Activation Signal.

- More 3.0L Toyota Camry Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Toyota Camry: 1992, 1993

IMPORTANT: Before testing the igniter, check the ignition coil for spark first.

If spark is present, it confirms the igniter is working properly and there's no need to proceed with this tutorial. If you haven't already tested the ignition coil, do so first:

Wiring Diagram:

Engine No-Start Diagnostics:

Symptoms Of A Bad Igniter

The igniter is the brain behind the ignition system. Its primary function is to receive commands from the fuel injection computer and activate the ignition coil to fire spark.

When the igniter fails, it will stop activating the ignition coil. The end result is an engine no-start problem due to a lack of spark.

Igniter Circuit Descriptions

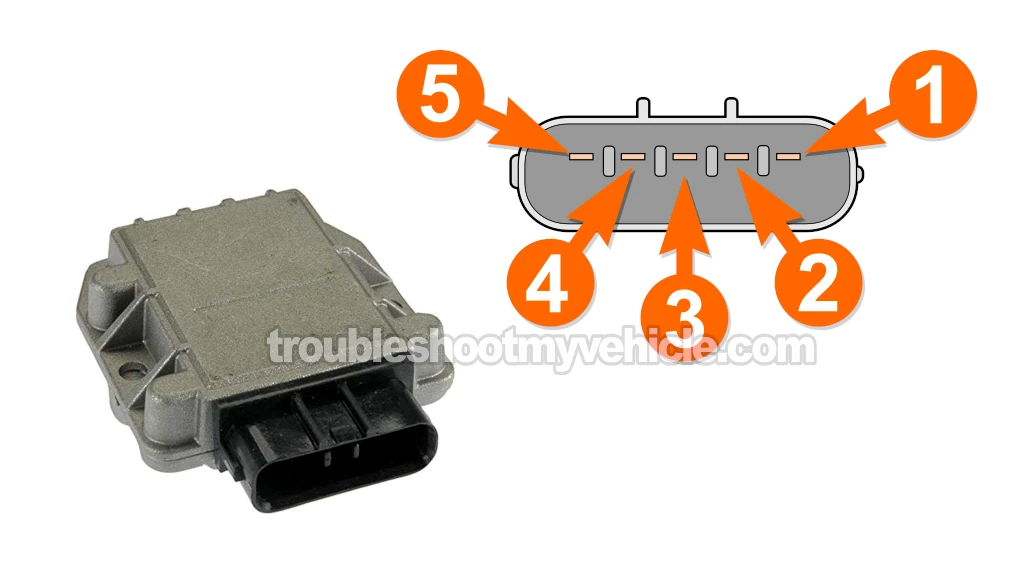

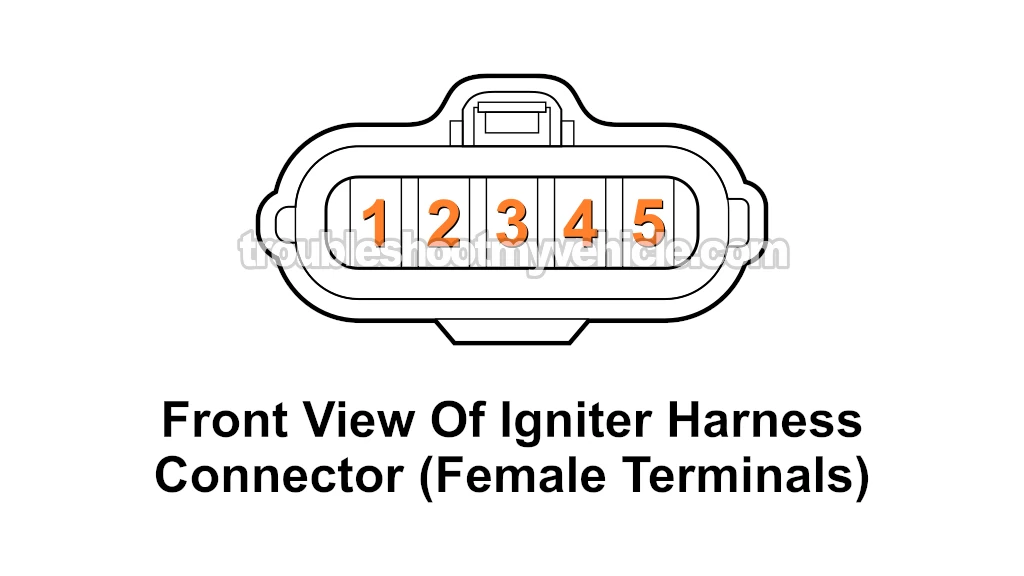

The igniter (ignition control module) has 5 wires coming out of its connector. Each one has a specific job to do and here's a brief description of each:

| Pin | Wire Color | Description |

|---|---|---|

| 1 | White with red stripe (WHT/RED) | IGF -Ignition coil firing feedback |

| 2 | White (WHT) | IGT -Igniter control signal |

| 3 | White with red stripe (WHT/RED) | +B -Battery power |

| 4 | Black (BLK) | IG- -Tachometer signal |

| 5 | Black with white stripe (BLK/WHT) | +B2 -Ignition coil control signal |

NOTE: The igniter harness connector has female metal terminals. You'll need to use a back probe or a wiring piercing probe to test the signals in the wires.

Basic Operation Theory Of The Igniter

When you turn the key and crank the engine on your 1992-1993 3.0L V6 Toyota Camry, several processes unfold that are essential for the ignition system to create and distribute spark to all six cylinders.

Here's what happens:

- The igniter receives power from the ignition switch (10 to 12 Volts DC).

- This power is supplied by the white with red stripe (WHT/RED) wire of the igniter's 5-wire connector. The WHT/RED wire also feeds power to the ignition coil.

- As you crank the engine, the crankshaft position (CKP) sensor and camshaft position (CMP) sensors in the distributor's pickup coil start generating their signals (NE, G1, and G2). These signals are transmitted directly to the fuel injection computer.

- Once the fuel injection computer receives these CKP and CMP position signals, it sends an activation (IGT) signal to the igniter.

- This IGT signal commands the igniter to activate the ignition coil to start firing spark.

- The IGT signal is delivered by the white (WHT) wire (of the igniter's 5-wire connector) to terminal number 2 of the igniter.

- When the igniter receives this activation signal, it sends its own activation (+B2) signal to the ignition coil via its terminal 5.

- This +B2 signal is sent on the black with white stripe (BLK/WHT) wire, which triggers the ignition coil to start sparking.

With this info under our belts, let's begin our tests.

TEST 1: Making Sure The Igniter Is Getting Power

IMPORTANT: If the ignition coil is creating and delivering spark to all six cylinders, the igniter is functioning correctly. If you haven't already tested the ignition coil for spark, please do so before testing the igniter:

To start our diagnostic, we're gonna make sure that the igniter itself is receiving the necessary voltage to function properly.

This simply involves verifying that the white with red stripe (WHT/RED) wire is providing 10 to 12 Volts DC when the key is turned to the ON position.

If the igniter is indeed receiving power, we can move on to TEST 2.

Let's get started:

- 1

Disconnect the igniter from its 5-wire electrical connector.

- 2

Connect the black multimeter test lead to the battery negative (-) terminal.

- 3

Have your helper turn the key to the ON position.

- 4

Place your multimeter in Volts DC mode.

- 5

Gently probe female terminal number 3 (of the 5-wire connector) with the red multimeter test lead.

NOTE: Verify that female terminal number 3 of the igniter's 5-wire connector corresponds to the WHT/RED wire. - 6

Your multimeter should read 10 to 12 Volts DC.

Let's take a look at what your test results mean:

CASE 1: The igniter is getting 10 to 12 Volts DC. This is the correct and expected test result. The next step is to make sure the igniter is getting Ground. For this step, go to: TEST 2: Making Sure The Igniter Is Getting Ground.

CASE 2: The igniter IS NOT getting battery power. This tells you that the igniter is not working due to a lack of battery power.

Your next step is to find out why this battery power is missing and restore it. Once battery power is restored, the igniter should function again.