TEST 2: Making Sure The Igniter Is Getting Ground

Now that you've confirmed that the igniter is getting power in TEST 1, the next step is to ensure it's getting Ground.

The igniter gets its Ground through its metal case, which means we'll need to do a resistance test with a multimeter to verify continuity between the igniter's case and the battery negative (-) post.

Let's begin:

- 1

Disconnect the igniter from its 5-wire electrical connector.

- 2

Disconnect the battery positive (+) cable from its cable.

NOTE: Leave the battery negative (-) cable connected to the battery negative (-) post. - 3

Set your multimeter to Ohms (Ω) mode.

- 4

Place one multimeter test lead on the igniter's metal case.

- 5

Place the other multimeter test lead on the center of the battery negative (-) post.

- 6

The multimeter should read continuity.

If there's continuity (a low resistance reading, usually close to 0 Ohms), the igniter is properly grounded.

If there's no continuity (infinite resistance or OL on the display), the igniter is not grounded.

Let's take a look at what your test results mean:

CASE 1: The igniter has continuity to Ground. This is the correct and expected test result.

The next step is to make sure the igniter is getting the IGT signal from the fuel injection computer. For this step, go to: TEST 3: Testing The Igniter Control Signal.

CASE 2: The igniter DOES NOT have continuity to Ground. This indicates a Ground issue, likely due to poor contact or corrosion between the igniter's case and its mounting surface.

Your next step is to inspect and clean the igniter's mounting points to ensure proper metal-to-metal contact. Once Ground is restored, the igniter should function as expected.

TEST 3: Testing The Igniter Control Signal

Alright, you've made it through the first round of tests! You've confirmed that:

- The ignition coil isn't sparking

- The igniter is receiving power (TEST 1)

- The igniter has a solid Ground connection (TEST 2)

Now, let's move on to the next step. We're gonna check if the fuel injection computer is sending an activation signal to the igniter.

As you crank the engine, the fuel injection computer starts generating the IGT signal based on input from the crankshaft position (CKP) and camshaft position (CMP) sensor in the pickup coil (in the distributor).

The IGT signal is the activation signal which tells the igniter when to start activating the ignition coil.

In this test, we'll use an LED light to detect the presence of the IGT signal while cranking the engine.

IMPORTANT: Do not use a 12 Volt test light instead of an LED light, or you'll damage the igniter. If you need to buy an LED light, go here: The LED Light Test Tool And How To Make One (at: easyautodiagnostics.com).

IMPORTANT: The igniter must remain connected to its electrical connector for this test to function. To access the IGT signal inside the wire, you'll need to use either a back probe on the connector or a wiring piercing probe. You can see an example of a wiring piercing probe here: Wire Piercing Probe Review (Power Probe PWPPPPP01) (at: easyautodiagnostics.com).

These are the test steps:

- 1

Connect the red LED wire to the white (WHT) wire of the igniter's electrical connector.

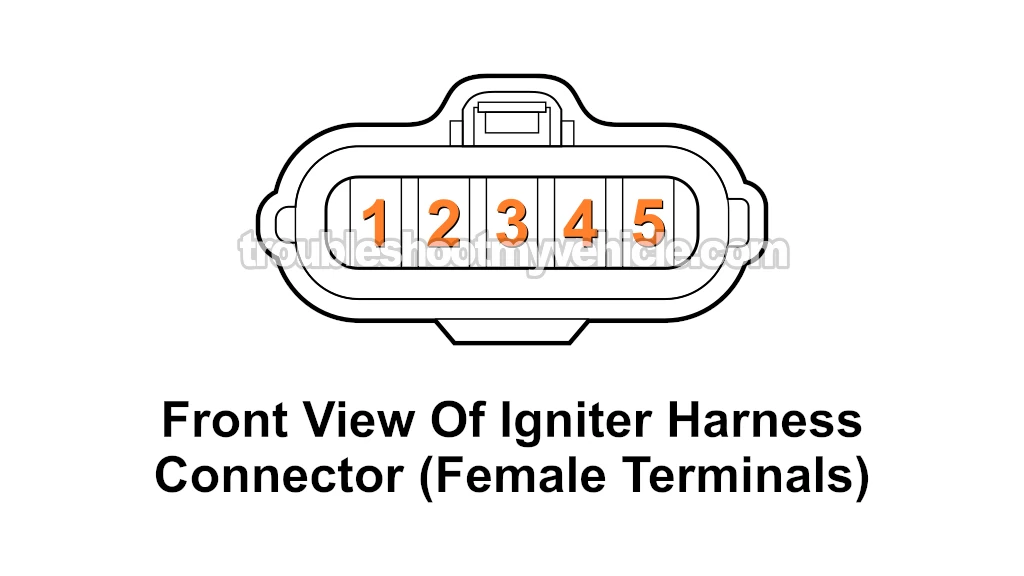

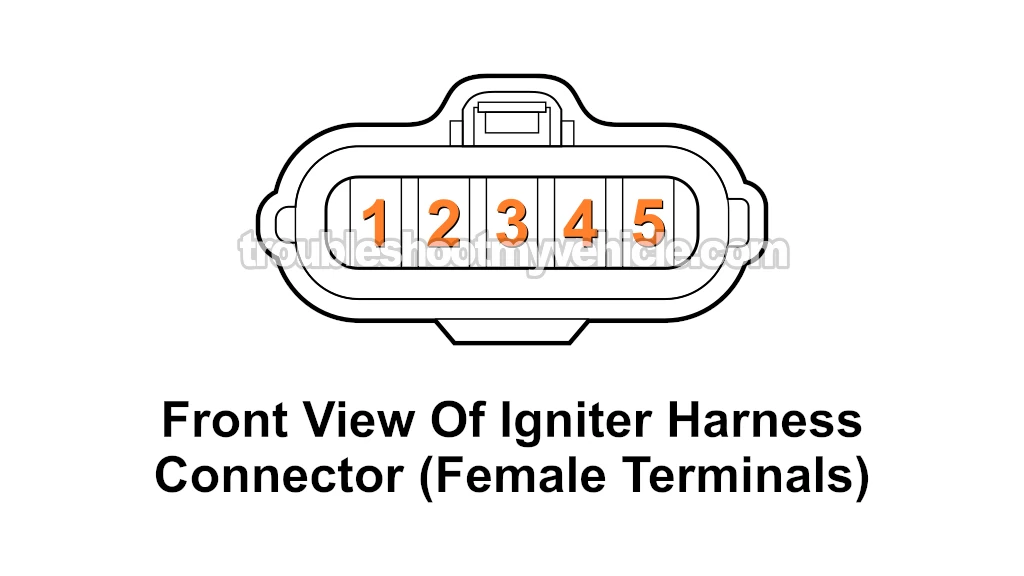

The WHT wire is the one that corresponds to female terminal number 2 of the igniter's 5-wire connector (see illustration above).

NOTE: The igniter must remain connected to its electrical connector. - 2

Connect the black LED wire to the battery negative (-) terminal.

- 3

After the LED light is set up, have your helper crank the engine as you observe the LED light.

- 4

The LED light should flash ON and OFF in steady pulses as the engine is cranking if the IGT signal is present.

Let's take a look at what your test results mean:

CASE 1: The LED light flashed ON and OFF. This is the correct and expected test result and tells you that the igniter is getting its activation signal from the fuel injection computer.

The next step is to make sure that the igniter is now creating the activation signal for the ignition coil. Go to: TEST 4: Testing The Ignition Coil Activation Signal.

CASE 2: The LED light DID NOT flash ON and OFF. This tells you that the igniter is not receiving its activation (IGT) signal from the fuel injection computer.

If the igniter doesn't receive its IGT signal, it's not gonna activate the ignition coil to start creating and sending spark to the distributor.

The most common reason the IGT signal is missing is a defective distributor pickup coil. The following tutorial will help you test the distributor's pickup coil:

TEST 4: Testing The Ignition Coil Activation Signal

Up to this point, your diagnostic tests have confirmed:

- The ignition coil isn't sparking

- The igniter is receiving power (TEST 1)

- The igniter has a solid Ground connection (TEST 2)

- The igniter is receiving its IGT activation signal (TEST 3).

For our last igniter diagnostic test, we're gonna verify if the igniter is sending the +B2 signal to the ignition coil.

This crucial signal is the one that activates the ignition coil to start sparking away. To detect its presence, we'll use an LED light to check for a pulse at the ignition coil's 2-wire connector.

IMPORTANT: The igniter must remain connected to its electrical connector for this test to function.

These are the test steps:

- 1

Disconnect the ignition coil from its 2-wire connector.

- 2

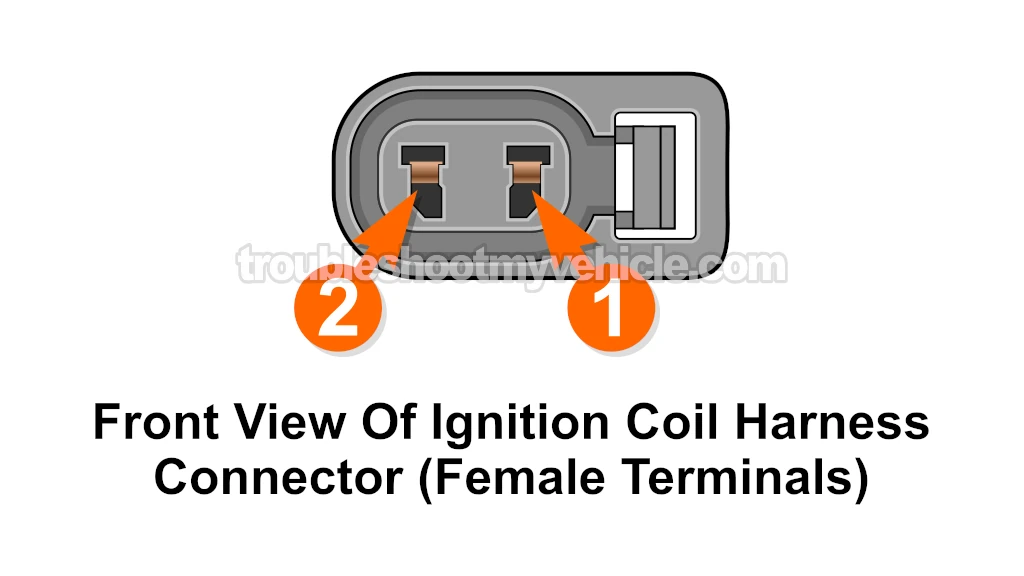

Connect the red LED wire to the female terminal labeled with the number 1 of the ignition coil harness connector (see illustration above).

The wire that connects to terminal 1 is a black with white stripe (BLK/WHT) wire.

CAUTION: You'll connect the LED wire to the female terminal of the connector. Do not insert a large diameter test lead into the female terminal of the ignition coil connector, or you'll damage the female terminal! - 3

Connect the black LED wire to the terminal labeled with the number 2 of the ignition coil harness connector (see illustration above).

The wire connecting to terminal 2 is a white with red stripe (WHT/RED) wire. - 4

After the LED light is set up, have your helper crank the engine as you observe the LED light.

- 5

The LED light should flash ON and OFF as the engine cranks.

Let's interpret your test result:

CASE 1: The LED light flashed ON and OFF. This is the correct and expected test result and tells you that the igniter is creating and sending an activation signal to the ignition coil.

This test result also confirms the igniter (ignition control module) is functioning correctly.

You can conclude that the ignition coil is bad and needs replacement only if you have confirmed that:

- The ignition coil is not sparking.

- The igniter is getting battery power and Ground (TEST 1 and 2).

- The igniter is getting the IGT signal (TEST 3).

- The igniter is creating/sending the +B2 signal to the ignition coil (this test section).

CASE 2: The LED light DID NOT flash ON and OFF. This tells you that the igniter is bad.

You can conclude that the igniter is defective and needs replacement only if you have tested and confirmed that:

- The ignition coil is not sparking.

- The igniter is getting battery power and Ground (TEST 1 and 2).

- The igniter is getting the IGT signal (TEST 3).

- The igniter IS NOT creating/sending the +B2 signal to the ignition coil (this test section).

More 3.0L Toyota Camry Tutorials

You can find a complete list of 3.0L Toyota Camry tutorials and wiring diagrams in this index:

Here's a sample of the tutorials you'll find there:

- How To Test Engine Compression (1992-2006 3.0L V6 Toyota Camry).

- How To Test For A Blown Head Gasket (1992-2006 3.0L V6 Toyota Camry).

- How To Test The TPS (1997-2001 3.0L V6 Toyota Camry).

- How To Test The MAF Sensor (1997-2001 3.0L V6 Toyota Camry).

If this info saved the day, buy me a beer!