On 2004 to 2010 Ford Explorers and Mercury Mountaineers with the 4.0L engine, testing the fuel pump driver module (FPDM) has become a standard step any time fuel pressure reads 0 PSI during a no-start diagnosis.

In this tutorial, I'll walk you through step-by-step tests to figure out if the FPDM module is toast —and let me tell you, diagnosing it is a whole lot easier than it looks.

In this comprehensive tutorial, we'll cover:

- VPWR (12V power input) and PWR GND (chassis Ground) tests.

- Fuel Pump Control (FPC) and Fuel Pump Monitor (FPM) signal verification.

- Making sure the FPDM is actually activating the fuel pump.

Let's get started!

Contents of this tutorial:

- Fuel Pump Driver Module (FPDM) Location.

- Fuel Pump Driver Module Basic Checks.

- Tools Needed To Check The FPDM.

- TEST 1: Checking The FPDM PWR (12 Volts) Circuit.

- TEST 2: Checking The PWR GND (Power Ground) Circuit.

- TEST 3: Checking Fuel Pump Activation.

- TEST 4: Checking The Fuel Pump Control (FPC) Signal.

- TEST 5: Checking The Fuel Pump Monitor (FPM) signal.

- More Fuel Pump Troubleshooting Help.

- More 4.0L V6 Ford Explorer And Mercury Mountaineer Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 4.0L V6 Ford Explorer: 2004, 2005, 2006, 2007, 2008, 2009, 2010.

- 4.0L V6 Mercury Mountaineer: 2004, 2005, 2006, 2007, 2008, 2009, 2010.

MORE FUEL PUMP DIAGNOSTIC RESOURCES: You can find fuel pump circuit wiring diagrams, related fuel pump tests, and the inertia switch tests in this section:

FPDM OPERATING THEORY: This guide explains how the FPDM works, a must read to wrap your head around how this returnless system works:

Fuel Pump Driver Module (FPDM) Location

Here's how the location of the FPDM, depending on the specific body style of your Explorer:

- 2004–2010 Ford Explorer (SUV): The FPDM is located inside the cargo area, behind the interior trim panel on the passenger-side rear quarter panel, just forward of the passenger side taillight.

- 2004–2010 Ford Explorer Sport Trac (pickup): The FPDM is mounted under the vehicle, on the passenger side, near the front of the fuel tank. It's exposed to the elements and often fails due to corrosion and moisture intrusion.

Accessing the FPDM (Explorer SUV)

- Step 1: Open the rear liftgate and fold down the second- and third-row seats (if equipped).

- Step 2: Remove the plastic trim along the rear cargo floor and around the right rear panel. You might need a trim tool or flathead screwdriver to pop the clips without breaking them.

- Step 3: Locate the FPDM —it's a small silver or black metal box mounted to the sheet metal.

Accessing the FPDM (Sport Trac Pickup)

- Step 1: Safely raise the vehicle or crawl underneath from the passenger side.

- Step 2: Look just forward of the fuel tank, near the frame rail. The FPDM is bolted to the underside of the body or frame rail.

- Step 3: Inspect the unit for corrosion damage —very common in this exposed location.

Fuel Pump Driver Module Basic Checks

Whether you're dealing with an engine no-start or engine performance issues (like low fuel pressure) on a 2004–2010 Explorer, the fuel pump driver module (FPDM) is a prime suspect.

I'm gonna walk you through a full diagnosis of the FPDM, one step at a time. But before we dive into the tests, there are two important first steps we need to take:

STEP 1 → Scan for Codes (P1233–P1237):

Start with a scan tool —one that can read Ford's enhanced (manufacturer-specific) codes. You're looking for trouble codes that point to fuel pump control circuit problems. The key ones are:

- P1233: Fuel Pump Driver Module Offline or Disabled (No communication from PCM).

- P1235: Fuel Pump Control Out Of Range (PCM can't regulate it properly).

- P1237: Fuel Pump Secondary Circuit Fault (often internal to the FPDM).

These codes are your first clue that the PCM either can't talk to the FPDM or isn't getting the expected feedback. If you're seeing one or more of these, we can move forward with the FPDM's electrical tests.

NOTE: If you have a P0191 (Fuel Rail Pressure Sensor Performance), keep in mind that the root cause might still be the FPDM failing to control pressure properly —even though the sensor gets blamed.

If there are no codes and the pump still won't run, don't stop here —some failures don't always throw a code. Let's see step 2.

STEP 2 → Check Fuel Pressure:

The next step, after checking for FPDM diagnostic trouble codes (DTCs), is to check the fuel pressure with a fuel pressure test gauge.

This is an often overlooked or skipped diagnostic step, but it's critical to know the exact fuel pressure the fuel pump is producing, independent of the data the fuel rail pressure (FRP) sensor is showing on the scan tool's "live data" fuel rail pressure PID (parameter ID).

If you haven't checked fuel pressure, this tutorial will help you with the test:

IMPORTANT: While this tutorial focuses mainly on diagnosing an engine no-start caused by a bad FPDM or a failed fuel pump, the step-by-step tests —especially the voltage drop test in TEST 2— can also help you track down performance issues caused by problems in the FPDM circuits.

Tools Needed To Check The FPDM

The most important tool you'll need is a multimeter that can read duty cycle %. Why? Because to check the PCM's command signal to the FPDM, the PCM sends it as a duty cycle % signal (called the FPC signal).

For you and me to successfully test the operation of the FPDM, we've got to measure that FPC signal and compare it to the manual's spec. And just as important —the feedback signal that the FPDM sends back to the PCM is also a duty cycle % signal.

Now, I don't mean a multimeter that can measure Hertz (Hz) frequency. I'm talking about one that specifically reads duty cycle %. If you've already got one —awesome, you're set to go. If not, this is the one I use all the time and recommend:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

You'll also need a few more things:

- Back-probe pins or piercing probe.

- These T-pins are the ideal back probe for the FPDM tests: Straight Pins T-Pins Stainless Steel (Amazon affiliate link)

- Battery jump start cable: We'll use a jump start cable to extend the reach of the multimeter test lead to the battery negative (-) post in TEST 2.

You're gonna need a wiring diagram of the FPDM circuits, and I've got you covered there too:

- Fuel Pump Circuit Wiring Diagram (2004 4.0L V6 Ford Explorer And Mercury Mountaineer).

- Fuel Pump Circuit Wiring Diagram (2005 4.0L V6 Ford Explorer And Mercury Mountaineer).

- Fuel Pump Circuit Wiring Diagram (2006-2010 4.0L V6 Ford Explorer And Mercury Mountaineer).

TEST 1: Checking The FPDM PWR (12 Volts) Circuit

Depending on the model year of your specific Explorer/Mountaineer, power from the fuel pump inertia switch is delivered to the FPDM by one of the following wires:

- White (WHT) —2004 to 2005.

- Violet with white stripe (VIO/WHT) —2006 to 2010.

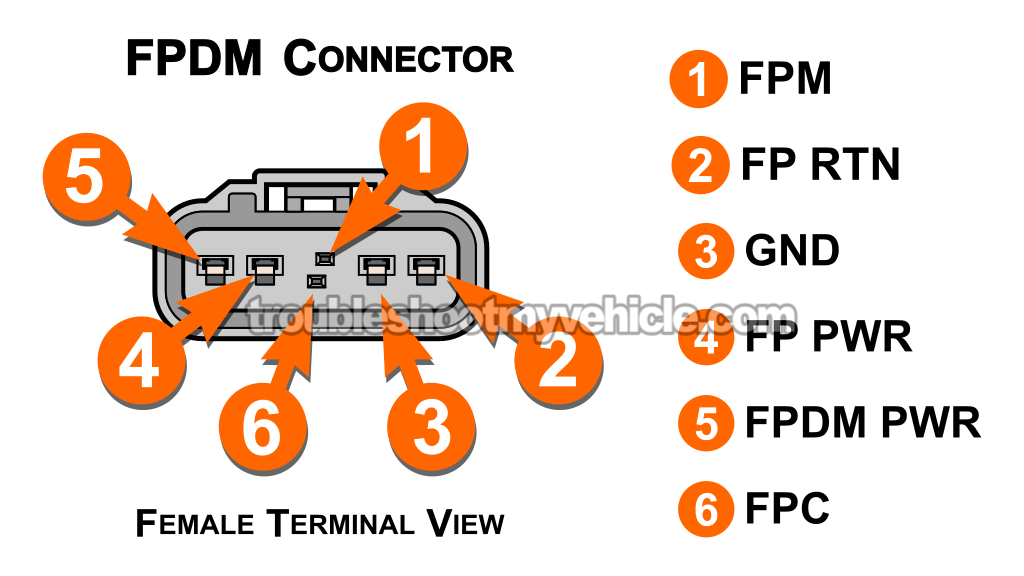

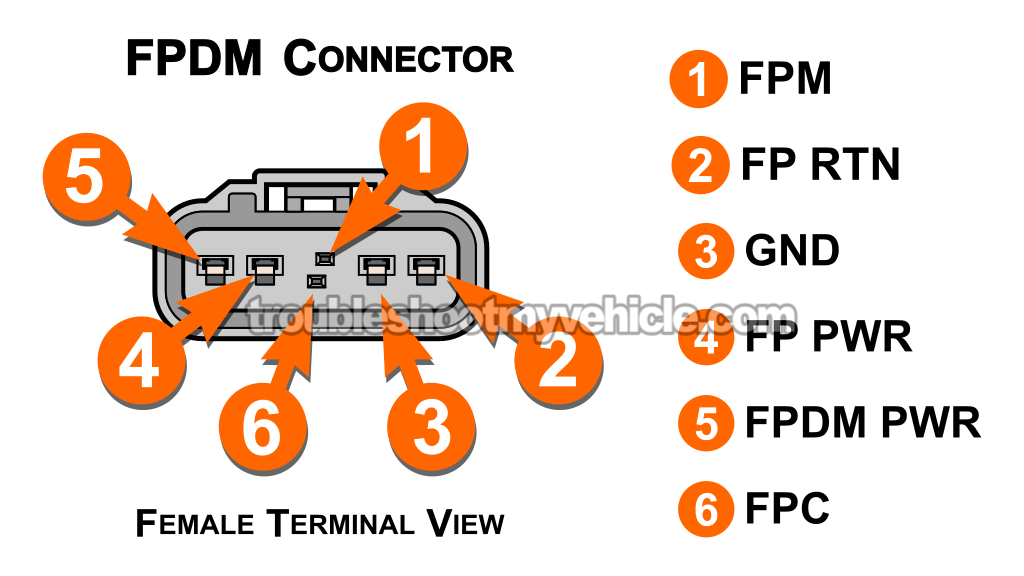

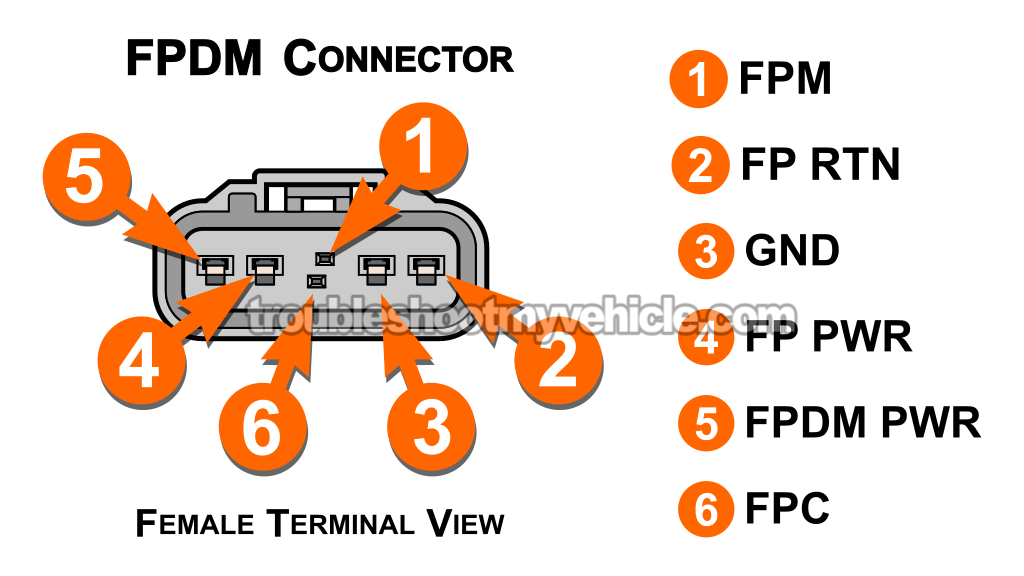

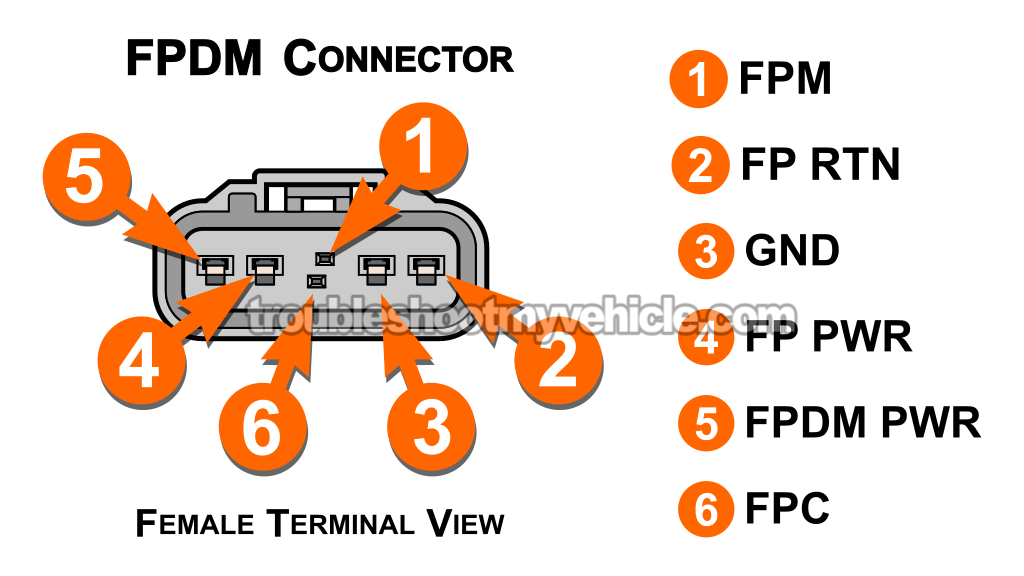

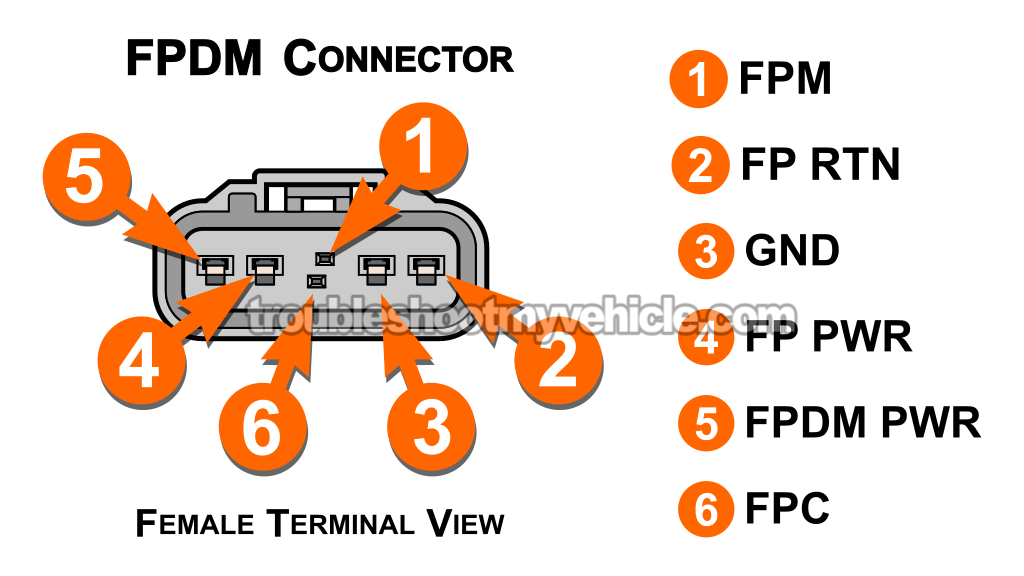

This wire connects directly to pin 5 of the FPDM's 6-wire connector and should carry full battery voltage when the ignition is in the RUN position.

NOTE: Use a back-probe pin or piercing probe to avoid damaging the connector. Don't jam test leads into the terminals —you'll widen them and cause future connection problems.

Alright, let's get the ball rolling:

- 1

Disconnect the FPDM from its 6-wire connector.

- 2

Turn the key to the RUN position (engine off) to get power flowing through the inertia switch circuit.

- 3

Set your multimeter to Volts DC mode.

- 4

Connect the black multimeter test lead to a clean, rust-free, and paint-free metal spot on the chassis (solid Ground).

- 5

Gently probe female terminal 5 of the connector.

Confirm that the WHT or VIO/WHT wire actually connects to pin 5. - 6

You should see close to battery voltage —between 10 and 12 Volts.

Let's interpret that test result:

CASE 1: Battery voltage (10–12 Volts) is present on the VIO/WHT wire. This tells you the inertia switch is not tripped, the fuse is good, and power is making it all the way to the FPDM. The VPWR circuit is working properly. Go to: TEST 2: Checking the PWR GND (Power Ground) Circuit.

CASE 2: No voltage (or less than 10 Volts) is present on the VIO/WHT wire. This means there's a break somewhere in the power feed circuit. Without 12 Volts, the FPDM won't function —and the fuel pump won't run.

The issue could be a blown fuse, a tripped or faulty inertia switch, or a damaged wire between the inertia switch and the FPDM. You're next step is to trace the circuit upstream to find the source of the issue and restore power to it.

TEST 2: Checking The PWR GND (Power Ground) Circuit

The fuel pump driver module (FPDM) relies on a clean, solid Ground to function correctly. Depending on your Explorer's model year, that Ground is supplied through one of the following wires:

- Black (BLK).

- Brown with green stripe (BRN/GRN).

- Black with green stripe (BLK/GRN).

Whichever wire your vehicle uses, it serves as the PWR GND circuit and connects to pin 3 of the FPDM's 6-wire connector.

Now, here's some important context to help you diagnose this circuit like a pro: both your vehicle's metal chassis and the engine block are connected to the battery's negative (-) terminal.

The FPDM's chassis Ground wire connects directly to the vehicle's metal chassis instead of connecting directly at the battery's negative (-) cable terminal (at the battery negative post).

Over time, corrosion builds up at these connection points —especially where Ground cables bolt to bare metal. That corrosion creates resistance in the FPDM's Ground path back to the battery.

This resistance leads to what's called a voltage drop, which can prevent the FPDM from getting a clean Ground —especially under load— and cause all kinds of weird behavior.

So instead of checking this wire with a basic continuity test in Ohms mode (which doesn't simulate real-world conditions), we're going to perform a proper voltage drop test. That way, we'll know for sure whether the FPDM has a solid, low-resistance Ground path when it's actually doing its job.

IMPORTANT: The FPDM must be connected to its connector to check the Ground wire's voltage drop.

Here's how to do it:

- 1

Reconnect the FPDM to its 6-wire connector.

- 2

Set your multimeter to Volts DC mode.

- 3

Connect the red multimeter lead to the PWR GND wire (pin 3) at the FPDM connector.

You can back-probe the connector or use a piercing probe on the wire itself. - 4

Connect the black multimeter lead directly to the battery negative (-) post.

IMPORTANT: This connection has to be done at the battery negative (-) post. I use a battery jump start cable to extend the reach of the multimeter test lead. - 5

Have a helper turn the key to the RUN position and crank the engine. You want the FPDM to be active and current to be flowing through the Ground circuit.

- 6

Your multimeter should show a voltage reading as close as possible to 0 Volts DC.

Any voltage reading at 5 or more Volts is considered a big problem.

Let's break down what the test result means:

CASE 1: The multimeter shows a value under 1 Volt. That's a solid Ground. This confirms the FPDM's PWR GND wire is connected directly and cleanly to battery negative, with almost no resistance in the path.

Our next step is to see if the fuel pump driver module is activating the fuel pump. Go to: TEST 3: Checking Fuel Pump Activation.

CASE 2: The multimeter shows 5 Volts or higher. This indicates excessive resistance in the Ground path and this voltage drop will cause some weird problems with the fuel pump (engine no-starts, low fuel pressure, intermittent no-starts, sudden engine stalls, etc).

You've got corrosion or a loose connection somewhere between the FPDM to chassis or chassis to battery negative cable terminal and this is interfering with current flow.

Your next step is to clean the all Ground terminals, whether at the battery, at the engine block or at chassis Ground points. Once you're done, repeat this test.

If this solves the fuel pump/FPDM issue, the voltage drop will be under 1 Volt and the FPDM will be able to activate the fuel pump.

TEST 3: Checking Fuel Pump Activation

Now that you've confirmed the FPDM is getting power and has a solid Ground, the next step is to see if it's actually doing its job —activating the fuel pump during cranking.

For this test, I usually use a 12 Volt test light. If you have one, great. If not, you can use a multimeter set to Volts DC. Either tool works just fine, as long as you can monitor voltage while the engine is being cranked.

Here's what you need to know:

- Pin 4 is the FP PWR (fuel pump power) feed to the fuel pump. Depending on the model year, pin 4 connects to:

- 2004-2005: The pink with black stripe (PNK/BLK) wire.

- 2006-2010: The yellow with gray stripe (YEL/GRY) wire.

- Pin 2 is the FP GND (fuel pump Ground) feed to the fuel pump. This Ground is controlled internally by the FPDM. Depending on the model year, pin 2 connects to:

- 2004-2005: The black with orange stripe (BLK/ORG) wire.

- 2006-2010: The white with brown stripe (WHT/BRN) wire.

This Ground circuit isn't static —it's pulse width modulated (PWM) to control fuel pressure output based on engine demand. When cranking the engine (to get it started), the FPDM applies almost 100% Ground.

What we're doing here is tapping into both wires to see if the FPDM is actually completing the circuit and delivering power to the pump when commanded.

IMPORTANT: The FPDM must remain connected to its 6-wire connector to confirm the fuel pump's activation.

Here are the test steps:

- 1

Insert a back-probe into the back of the FPDM connector at pin 4 (FP VPWR).

Pin 4 should correspond to the YEL/GRY (2006-2010) or PNK/BLK (2004-2005) wire.

If you're using a multimeter, connect the red test lead here. - 2

Insert a back-probe into the back of the FPDM connector at pin 2 (FP GND).

Pin 2 should correspond to the WHT/BRN (2006-2010) or BLK/ORG (2004-2005) wire.

If using a multimeter, connect the black test lead here. - 3

If using a test light: Connect the alligator clip to one of the back-probes (either one), and touch the probe tip to the other.

- 4

Have your helper crank the engine while you observe the test light or multimeter reading.

- 5

If the FPDM is working correctly:

The test light will turn on and stay lit during cranking.

If using a multimeter, you'll see 9 to 12 Volts while the engine is cranking.

Let's interpret your test results:

CASE 1: The test light turns on (or the multimeter reads 9–12 Volts) during cranking. This is the correct result. It tells us four important things:

- The FPDM is receiving the activation command (FPC signal) from the PCM.

- The FPDM is successfully activating the fuel pump by powering up the FP PWR circuit.

- The FPDM is successfully activating the fuel pump by completing the Ground (FP GND) circuit.

- The FPDM itself is functioning properly under load.

So, if the engine still isn't starting and your fuel pressure gauge reads 0 PSI, then the fuel pump is the problem —it's getting power and Ground, but not producing pressure. Time to replace the pump.

CASE 2: The test light does not turn on, or the multimeter shows 0 Volts during cranking. That means the FPDM is not activating the pump. Double-check all your test connections and repeat the test to be sure.

If the result is the same, then it's time to check the FPC (Fuel Pump Control) signal from the PCM to the FPDM. Go to: TEST 4: Checking the Fuel Pump Control (FPC) Signal.

TEST 4: Checking The Fuel Pump Control (FPC) Signal

So far, you've confirmed the FPDM has power (TEST 1), a good Ground (TEST 2), and that it's not activating the fuel pump (TEST 3).

Now it's time to find out whether the PCM is sending a control signal —the Fuel Pump Control (FPC) signal— to the FPDM.

The FPC signal is a duty cycle (%) command that tells the FPDM how much pressure the PCM wants from the fuel pump. Here's how it works:

- A low duty cycle (closer to 5%) means the PCM is requesting lower fuel pressure.

- A higher duty cycle (closer to 50%) means the PCM wants more fuel pressure.

- At 50% duty cycle, the PCM is asking for maximum output —full fuel pump speed and full pressure.

Since your Ford's returnless fuel system doesn't use a fuel pressure regulator or a return line to control pressure and send excess fuel back to the tank, it handles fuel delivery differently. The PCM doesn't switch the pump ON using an old-school relay (like in the good old days).

Instead, it fine-tunes fuel pressure by varying the duty cycle of the FPC control signal sent to the FPDM. The FPDM then adjusts the pump's output based on that signal —more duty cycle means more fuel pressure, less duty cycle means less fuel pressure.

Now, to read this signal correctly, you'll need a multimeter that supports duty cycle (%) mode. Some meters only read frequency in Hertz (Hz), which won't help here. If you don't have one, this is the one I personally use and recommend —it reads duty cycle and won't break the bank:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

IMPORTANT: The FPDM must stay plugged into its 6-wire connector during this test.

Here's how to do it:

- 1

Set your multimeter to duty cycle (%) mode.

- 2

Connect the black multimeter lead to a clean, rust-free Ground point.

- 3

Back-probe the FPDM connector at the wire that carries the FPC signal:

2004-2005 → it'll be a dark green with yellow stripe (DK GRN/YEL) wire.

2006-2010 → it's a yellow with orange stripe (YEL/ORG) wire. - 4

Have your helper crank the engine while you monitor the multimeter.

- 5

You should see a duty cycle reading around 50% during cranking (if the engine isn't starting).

NOTE: Ford considers any duty cycle between 5% and 50% as normal with the engine running. During startup conditions the reading is usually around 50%.

Let's interpret your test result:

CASE 1: The FPC signal is present (around 40% to 50% duty cycle). This means the PCM is doing its job and commanding the FPDM to activate the pump. If the pump still isn't running and you've already:

- Confirmed power to the FPDM (TEST 1),

- Confirmed a solid Ground connection (TEST 2), and...

- Confirmed no fuel pump activation (TEST 3),

Then the FPDM is not responding to its command and is faulty. Replace the FPDM module. Before you replace the module, it's important you check the fuel pump's amperage draw (to avoid frying the new one):

CASE 2: No FPC signal is present. Without this signal, the FPDM will never activate the pump.

This usually points to an open-circuit problem in the FPC circuit wire between the FPDM connector and the PCM connector.

Your next step is find out why this signal is missing and repair the issue to get the signal delivery restored.

OPTIONAL: You can bypass the FPDM and activate the fuel pump, this tut will show you how:

TEST 5: Checking The Fuel Pump Monitor (FPM) signal

NOTE: This test is optional. Its main purpose is to show you how to check the FPM (Fuel Pump Monitor) signal if you ever need to verify that the FPDM is reporting back to the PCM correctly.

If the fuel pump driver module (FPDM) is functioning properly —getting its power, Ground, and command input— and is actively controlling the fuel pump (whether the pump is good or bad), it will send a 50% duty cycle feedback signal back to the PCM.

This FPM signal travels on one of two wires, depending on your Explorer's model year:

- 2004–2005: Light blue with orange stripe (LT BLU/ORG)

- 2006–2010: Yellow with orange stripe (YEL/ORG)

The FPDM uses this signal to tell the PCM what's happening in the fuel pump circuit. It can output three possible duty cycles:

- 25% duty cycle: The FPDM did not receive a valid FPC signal from the PCM.

- 50% duty cycle: Normal operation. The FPDM received the command and everything looks good.

- 75% duty cycle: The FPDM detected a fault in the circuit between itself and the fuel pump (open, short, overcurrent, etc.).

In this test, we're simply confirming that the FPDM is sending some kind of valid feedback signal back to the PCM—whether it's 25%, 50%, or 75%. Seeing any of these confirms that the feedback line is alive and the module is communicating.

Alright, let's get to it:

- 1

Set your multimeter to duty cycle (%) mode.

- 2

Connect the black multimeter lead to a clean, rust-free Ground point.

- 3

Back-probe the FPDM connector at the wire that carries the FPM signal:

2004–2005: Light blue with orange stripe (LT BLU/ORG)

2006–2010: Brown with white stripe (BRN/WHT). - 4

Have your helper crank the engine while you monitor the multimeter.

- 5

You should see a duty cycle reading around 50% during cranking (assuming the engine isn't starting).

NOTE: You may see a reading of 25% or 75% instead —both are valid signals and indicate the FPDM is alive and communicating.

Let's interpret your test result:

CASE 1: A 50% duty cycle FPM signal is present. This means the FPDM considers itself healthy and sees no issues with the system.

Here's how to interpret that:

- If fuel pressure is 0 PSI and the engine isn't starting due to lack of fuel, then the fuel pump is bad —especially if you've already confirmed in TEST 3 that the FPDM is sending power and Ground to the pump.

- If fuel pressure is within spec and the engine still isn't starting, then the fuel pump is not the issue. Something else is keeping the engine from starting.

CASE 2: A 25% or 75% duty cycle FPM signal is present. This means the FPDM sees a problem and is reporting it to the PCM.

- 25% duty cycle: The FPDM is either:

- Not receiving a Fuel Pump Control (FPC) command signal from the PCM,

- Receiving an invalid FPC signal (outside the expected 5%–50% range —fuel pump "ON" command), or...

- Not receiving the PCM's "OFF" command, which is typically a 70%–80% duty cycle.

- 75% duty cycle: This indicates a problem between the FPDM and the fuel pump —either the pump itself is faulty, or there's an open or short in the power or Ground wiring to the pump.

CASE 3: No FPM signal is present. This usually means the FPDM isn't powering up at all. The most common cause is a tripped inertia switch, which blocks power from reaching the module.

If power is getting to the FPDM, the next most likely issue is a poor chassis Ground —check for rust, corrosion, or a loose connection.

If both power and Ground circuits are good, and there's still no FPM signal, then the FPDM has failed and needs to be replaced.

More Fuel Pump Troubleshooting Help

FUEL PUMP PRESSURE TESTS:

FUEL PUMP AMPERAGE DRAW TESTS:

FUEL PUMP DRIVER MODULE (FPDM) TESTS:

- FPDM Basic Operating Theory (2004-2010 4.0L V6 Ford Explorer And Mountaineer).

- Bypassing The FPDM Module (2004-2010 4.0L V6 Ford Explorer And Mercury Mountaineer).

FUEL PUMP INERTIA SWITCH TESTS:

- Fuel Pump Inertia Switch Tests (1991-2010 4.0L V6 Ford Explorer, Aerostar, And Mercury Mountaineer).

- Power To Fuel Pump Check (1991-2010 4.0L V6 Ford Explorer, Aerostar, And Mercury Mountaineer).

ENGINE NO-START DIAGNOSTICS:

FUEL PUMP CIRCUIT DIAGRAMS:

- Fuel Pump Circuit Wiring Diagram (2004 4.0L V6 Ford Explorer And Mercury Mountaineer).

- Fuel Pump Circuit Wiring Diagram (2005 4.0L V6 Ford Explorer And Mercury Mountaineer).

- Fuel Pump Circuit Wiring Diagram (2006-2010 4.0L V6 Ford Explorer And Mercury Mountaineer).

More 4.0L V6 Ford Explorer And Mercury Mountaineer Tutorials

I have written several more 4.0L V6 Explorer/Mountaineer specific test articles. You can find them all here:

The following tutorials are a sample of the articles you'll find in the index:

- How To Test The CKP Sensor (1997-2010 4.0L V6 Ford Explorer And Mercury Mountaineer).

- Fuel Pressure Specifications (1991-2010 4.0L V6 Ford Explorer, Mercury Mountaineer).

- How To Test For A Blown Head Gasket (1991-2010 4.0L V6 Ford Explorer, Aerostar, And Mercury Mountaineer).

- Troubleshooting P0171 And P0174 (1996-2003 4.0L V6 Ford Explorer, Aerostar, And Mercury Mountaineer).

If this info saved the day, buy me a beer!