At first glance, pinpointing a bad fuel injector on your 1996-1998 3.0L V6 Nissan Quest or Mercury Villager looks like an impossible job. But trust me, it's not as hard as it seems.

In this tutorial, I'm going to show you how to check the internal resistance of all six fuel injectors —including the three located underneath the intake manifold plenum— right from your minivan's PCM connector using only a multimeter.

With your test results, you'll quickly and easily find out if you've got a fuel injector circuit that has suffered an electrical problem and is causing its cylinder to misfire, without having to remove the intake plenum.

Contents of this tutorial:

- Symptoms Of A Defective Fuel Injector.

- Where To Buy The Fuel Injector.

- Testing The Fuel Injector Resistance.

- Checking The Injector's Resistance Directly At Its Terminals.

- The Intake Manifold Plenum Has To Be Removed.

- How To Find The Bad Or Clogged Fuel Injector.

- More 3.0L V6 Nissan Quest Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Nissan Quest: 1996, 1997, 1998.

- 3.0L V6 Mercury Villager: 1996, 1997, 1998.

FUEL INJECTOR CIRCUIT DIAGRAMS:

1993-1995 FUEL INJECTOR TESTS:

Symptoms Of A Defective Fuel Injector

As you're already aware, each of the six cylinders in your Nissan Quest (Mercury Villager) needs three things to function properly: spark, fuel, and compression. And as you've guessed, it's the fuel injector that provides the fuel that the cylinder needs to initiate and complete its combustion cycle.

When a fuel injector fails to inject fuel, engine performance is going to suffer, and you're going to see one or more of the following issues:

- Cylinder misfire.

- Rough idle.

- Lack of power —especially when accelerating the engine under load (transmission in Drive).

Fuel injectors can suffer one of several types of failures. These are the ones I've encountered on these minivans:

- The injector suffers an internal open-circuit or short-circuit. When this happens, it stops injecting fuel completely.

- The injector becomes clogged —either partially or completely. A partially clogged injector will still spray fuel, but not in a proper conical pattern, and this will absolutely affect engine performance.

- The fuel injector connector becomes damaged. Usually, the insulation on the wires cracks and peels off right where the wires exit the connector. Eventually, enough insulation is gone that the copper strands become exposed and short together.

In this tutorial, I'm going to help you check that the fuel injector hasn't suffered an internal electrical issue and that its connector is in good shape. I'm also going to lay out a diagnostic strategy you can use to figure out if you've got a clogged fuel injector on your hands —assuming your test results show that all six injectors haven't suffered an internal electrical failure.

Where To Buy The Fuel Injector

If you find that you've got a bad fuel injector on your Nissan Quest (or Mercury Villager) and the time has come to swap it out, I want to make the following recommendations. These are fuel injectors from known automotive brands that I don't hesitate to recommend:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

NOTE: Not sure if the fuel injectors fit your particular Nissan Quest or Mercury Villager? Don't worry. Once you get to the site, they'll ask you for the specifics of your vehicle and check to see if the part fits. If it doesn't, they'll find the right one for you.

Testing The Fuel Injector Resistance

The Nissan repair manual specifies that each fuel injector should have an internal resistance between 10 and 14 Ohms. Over time, as they age and wear out, they'll develop one of two electrical problems:

- An internal open-circuit —your multimeter will show infinite Ohms, confirming that the injector has an internal break in its winding.

- An internal short-circuit —your multimeter will show 0 Ohms, confirming that the injector has shorted internally.

The only thing that complicates checking injector resistance directly at their two terminals is that three of them are located underneath the intake manifold plenum. Thankfully, we can get around this by checking the entire fuel injector circuit —meaning the injector and the wiring between it and the PCM— right from the PCM connector.

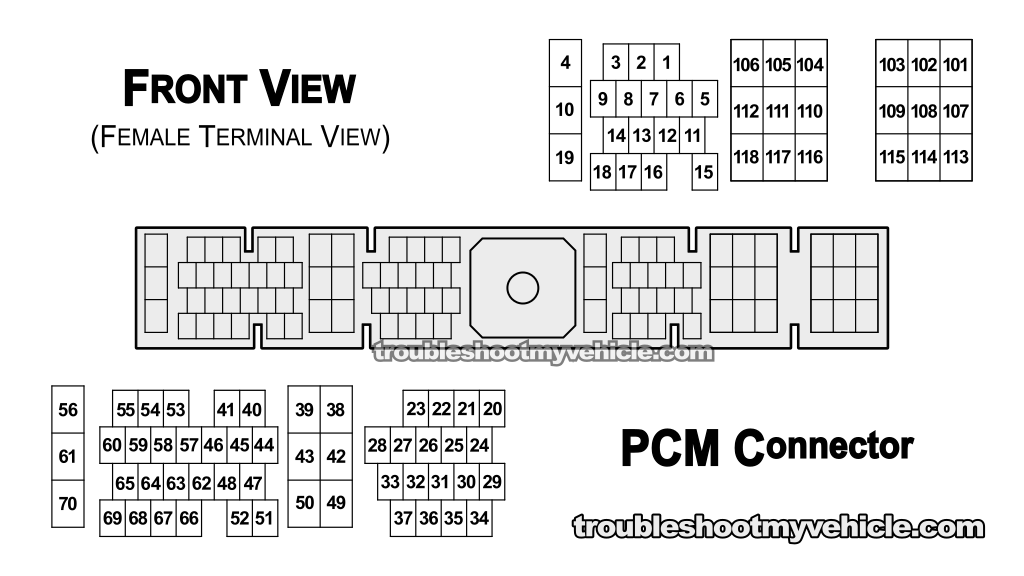

Before you begin, I want to point out that the PCM connector on your Nissan Quest or Mercury Villager is not a weather-sealed connector. So the standard procedure for checking any circuit at the connector is to back-probe it right where the wires exit the connector.

You can probe the front of the female terminals, but you've got to take a few precautions. Specifically, you must use multimeter test leads that have very thin metallic probes. Standard multimeter leads are too thick and can easily damage the female terminals (or the connector) if you try to force them in from the front.

I've written a detailed guide on how to safely probe the PCM connector on your Nissan Quest or Mercury Villager, and you can find it here: How To Safely Probe The PCM Connector -Without Damaging It (1993-1998 3.0L V6 Nissan Quest).

PCM LOCATION: On your 1996-1998 Nissan Quest or Mercury Villager, the PCM (powertrain control module/fuel injection computer) is located underneath the front passenger seat.

NOTE: If you don't have a multimeter or you need to upgrade the one you've got, this is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

OK, let's get going:

- 1

Disconnect the battery's negative cable and leave it disconnected for the entire test.

NOTE: This step is important. Don't move on to the next step without first disconnecting the negative battery cable from the battery. - 2

Disconnect the PCM from its connector.

- 3

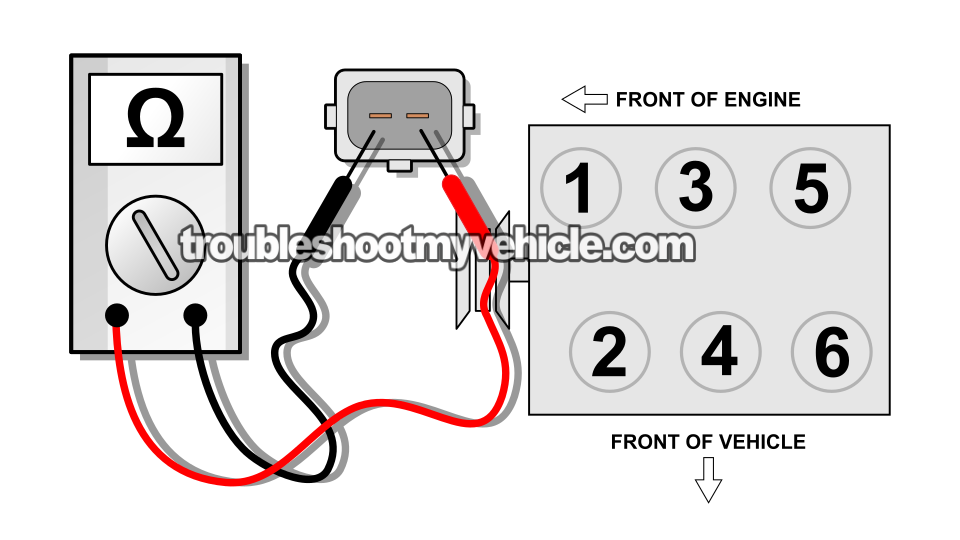

Set your multimeter to Ohms mode.

- 4

With your multimeter test leads —and the appropriate tool— back probe between the following terminals of the PCM connector:

—BANK 1 UNDER INTAKE MANIFOLD PLENUM:

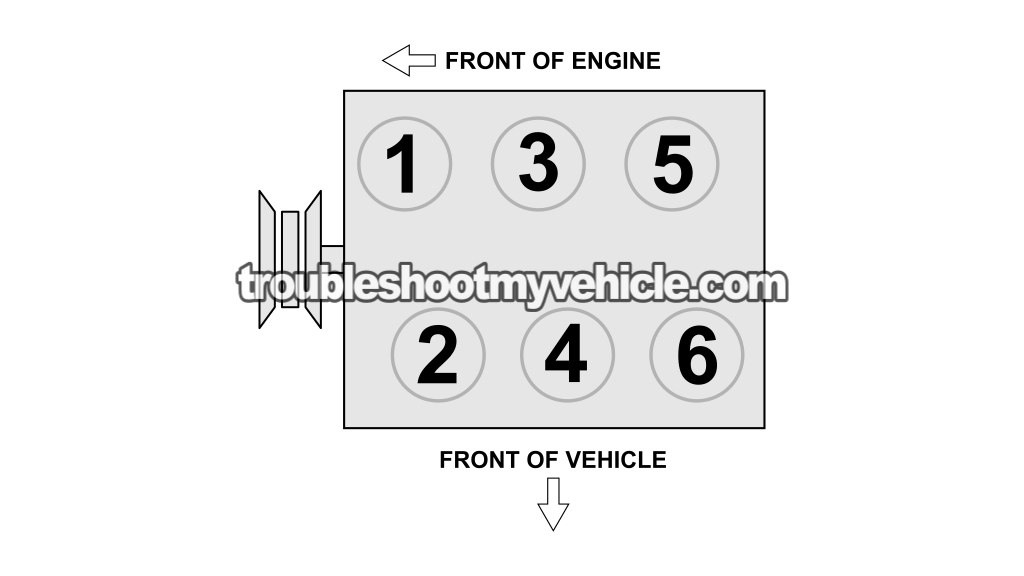

- Injector 1: Pins 102 (GRN/ORG) and 70 (YEL).

- Injector 3: Pins 104 (GRN/RED) and 70 (YEL).

- Injector 5: Pins 111 (YEL/GRN) and 70 (YEL).

—BANK 2:

- Injector 2: Pins 107 (GRN) and 70 (YEL).

- Injector 4: Pins 109 (YEL/PPL) and 70 (YEL).

- Injector 6: Pins 114 (GRY/BLU) and 70 (YEL).

NOTE: Use the connector pinout above to locate VPWR (pin 70) and the injector pins.

- 5

Write the resistance value down on a piece of paper, and make sure you note which injector that value belongs to.

- 6

Your multimeter should report a resistance between 10 and 14 Ohms for each injector circuit.

If the meter shows an open-circuit, a short-circuit, or a resistance outside the 10-14 Ohm range, that injector circuit is bad.

Let's analyze your multimeter test results:

CASE 1: All fuel injector circuit resistances are within the indicated specification. With this test result, we can rule out the fuel injectors —and the wiring between them and the PCM connector— as having an open or short-circuit issue.

That said, there's still a good chance that one of the six injectors is clogged. A clogged injector can still pass the resistance test, but fail to deliver fuel correctly. It may be injecting too little, or not injecting any at all —and any one of these conditions will cause a cylinder misfire.

To keep troubleshooting the issue, head over to: How To Find The Bad Or Clogged Fuel Injector.

CASE 2: One or more fuel injectors showed infinite Ohms or zero Ohms. This result tells us, without a doubt, that you've got a fuel injector issue on your Nissan Quest or Mercury Villager.

What it doesn't tell us yet is whether the injector itself has failed or if the problem is somewhere in the wiring between the injector connector and the PCM. So our next step is to narrow that down, go to: Checking The Injector's Resistance Directly At Its Terminals.

Checking The Injector's Resistance Directly At Its Terminals

If you've made it to this part of the tutorial, then at least one of your fuel injector circuits didn't pass the resistance test. Your multimeter likely showed one of three things:

- Infinite Ohms —the fuel injector circuit is open somewhere.

- 0 Ohms —the circuit is shorted.

- A resistance reading that's simply out of spec —not an open or short-circuit problem, but still not normal.

These failed resistance readings are usually caused by one of two things: the fuel injector itself or the injector's connector. And when it is the connector, it's almost always an issue with the two wires coming out of it. To figure out which one is causing the trouble, we need to do two things:

- Inspect the injector connector and its two wires.

- It's very common on these older Nissan Quest and Mercury Villager minivans for the insulation on these wires to crack or peel right where they exit the connector. Once that insulation breaks down, the copper strands get exposed —and they can easily short together.

- Check the injector's resistance directly at its two terminals.

- The injector itself may have suffered an internal electrical failure —and honestly, this is usually the most likely cause when the circuit fails the earlier test.

- When you measure resistance right at the injector's pins, you should see 10 to 14 Ohms.

The only "wrinkle" in this whole process is when the failed injector circuit belongs to cylinders 1, 3, or 5. The injectors for those cylinders sit underneath the intake manifold plenum, and that makes getting to them a little more involved.

If the problem points to one of those injectors, you'll need to remove the plenum to check the injector's resistance right at its terminals and to inspect the connector and its wires up close. Before you begin, take a look at this section: The Intake Manifold Plenum Has To Be Removed.

For injectors on cylinders 2, 4, or 6, life is much easier since they're fully accessible, and the intake manifold plenum isn't an issue to continue your diagnosis.

The Intake Manifold Plenum Has To Be Removed

There's no doubt that removing the intake manifold plenum is a bit of a challenge, but it's completely doable. I've pulled the plenum on these Nissan Quest and Mercury Villager vans more than a few times, and I can tell you it's not nearly as complicated as it looks. That said, there are a few precautions you'll want to follow to avoid unnecessary headaches.

- Cover the lower intake ports. Once the plenum is off, place clean shop towels over the exposed lower intake manifold runners. This is critical. You do not want a bolt, washer, or any other metal piece falling into one of those ports while you're testing the injectors.

- Keep removed hardware stored from the engine compartment. As you remove bolts and nuts, drop them into a small container and keep it away from the engine bay. It's way too easy for something to slip and disappear into a spot where you don't want it.

- Use new gaskets —and install them dry. When you reinstall the plenum, use fresh gaskets and don't apply any type of sealant. These gaskets are designed to be installed dry, and they'll seal just fine on their own.

- If you find a bad injector connector, solder the replacement. Don't use crimp-style butt connectors. They won't hold up to heat and vibration, and you'll end up right back where you started —with a misfire. Soldering the new connector into the harness is the only long-term, reliable fix.

One last thing —and I really want to stress this: Don't let anything fall into the open lower intake manifold runners. If a bolt, nut, or any small piece drops into one of those ports and you crank the engine, that cylinder is going to be in a world of hurt. The piston and valves can get damaged almost instantly, and the only way to get the debris out— and see how much damage was done— is to pull one or both cylinder heads.

How To Find The Bad Or Clogged Fuel Injector

With a solid diagnostic strategy, figuring out whether a bad or clogged fuel injector is causing a cylinder misfire or rough idle on your 1996-1998 Nissan Quest or Mercury Villager becomes a piece of cake.

Yep, knowing exactly where to start and what to test will save you a ton of time —and keep you from replacing parts that won't fix the problem— because quite a few things can cause a misfire or rough idle on these engines.

In this section, I'm going to walk you through the diagnostic strategy that I've used my entire automotive career to pinpoint the exact cause of a cylinder misfire or rough idle. This approach works beautifully on the 3.0L V6 in the Nissan Quest and Mercury Villager, and it'll help you zero in on the true source of the problem without any guesswork.

OK, this is the step-by-step of what I do.

- Identify the dead cylinder:

- On your 1996-1998 OBD II equipped Quest or Villager, this part is easy. The PCM will usually set a cylinder-specific misfire code that points you straight to the problem cylinder.

- If you don't have a misfire code, you'll need to perform a manual cylinder balance test. If you've never done one before, don't worry —I've written a step-by-step tutorial that walks you through it: How To Do A Manual Cylinder Balance Test (1993-1998 3.0L V6 Nissan Quest).

- Make sure that the dead cylinder is getting spark:

- This spark test should be done with a spark tester to make sure the spark plug wire for the dead cylinder is actually delivering spark to its spark plug.

- We also need to inspect the spark plug wire along its entire length. There shouldn't be any signs of damage or anything that'll let the spark arc to Ground before reaching the spark plug.

- The next step is to remove the dead cylinder's spark plug and give it a good look. We need to make sure its air gap isn't blocked with carbon deposits, that its porcelain insulator isn't cracked, and that the insulator isn't covered in carbon tracks. In short, the spark plug should be as close to perfect condition as possible.

- Don't forget to check inside the spark plug wire boot for carbon tracks. If a carbon track is present, the spark will take the easy way out —it'll jump to the engine block instead of firing the spark plug.

- Carbon tracking is a very common ignition problem. Here's a real-world example (case study) of carbon tracks causing a cylinder misfire: Carbon Tracks Are A Common Cause Of Ignition Misfires (at: easyautodiagnostics.com).

- Check that the dead cylinder has good compression:

- We need to confirm that the cylinder can actually compress its air-fuel mixture —because if it can't build compression, it's going to misfire, even if it's getting spark and fuel from its fuel injector.

- If you've never done a compression test before, I've put together a tutorial that shows you exactly how to perform the test and how to interpret the results: How To Do And Interpret An Engine Compression Test (1993-1998 3.0L V6 Nissan Quest).

- Check the internal resistance of the dead cylinder's fuel injector:

- Once spark and compression are ruled out as the causes of the dead cylinder's misfire, the next step is to check its injector's internal resistance.

- If the injector's resistance is outside of specification, then you've found the cause of the misfire —the injector is toast.

- If the resistance is within spec, and you've already confirmed that the cylinder is getting spark and has good compression, then the injector is almost always clogged. Even though it passes the resistance test electrically, it's not delivering fuel mechanically. At that point, the next step is to replace the injector.

At the core of the diagnostic strategy I've laid out is a simple process of elimination. The first step —and really the most important one— is identifying the dead cylinder. Once you know which cylinder isn't pulling its weight, everything else becomes a lot easier. From that point on, all you're doing is figuring out what that cylinder is missing. Is it missing spark? Is it missing compression? Is it missing fuel?

The beauty of checking these three basics is that it saves you both frustration and money. By confirming spark, compression, and fuel before replacing anything, you avoid throwing parts at the problem and ending up right back where you started.

More 3.0L V6 Nissan Quest Diagnostic Tutorials

You can find a complete list of 3.0L V6 Nissan Quest and Mercury Villager tutorials in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Ignition Coil And Power Transistor (1993-1998 3.0L V6 Nissan Quest).

- How To Test The Camshaft Position Sensor (1993-1998 3.0L V6 Nissan Quest).

- How To Test For A Blown Head Gasket (1993-1998 3.0L V6 Nissan Quest).

- Common Causes Of Spark Plug Failure (1993-1998 3.0L V6 Nissan Quest).

If this info saved the day, buy me a beer!