Checking the fuel injectors to see if you've got one or more with an internal electrical problem —keeping it from injecting fuel— isn't that difficult.

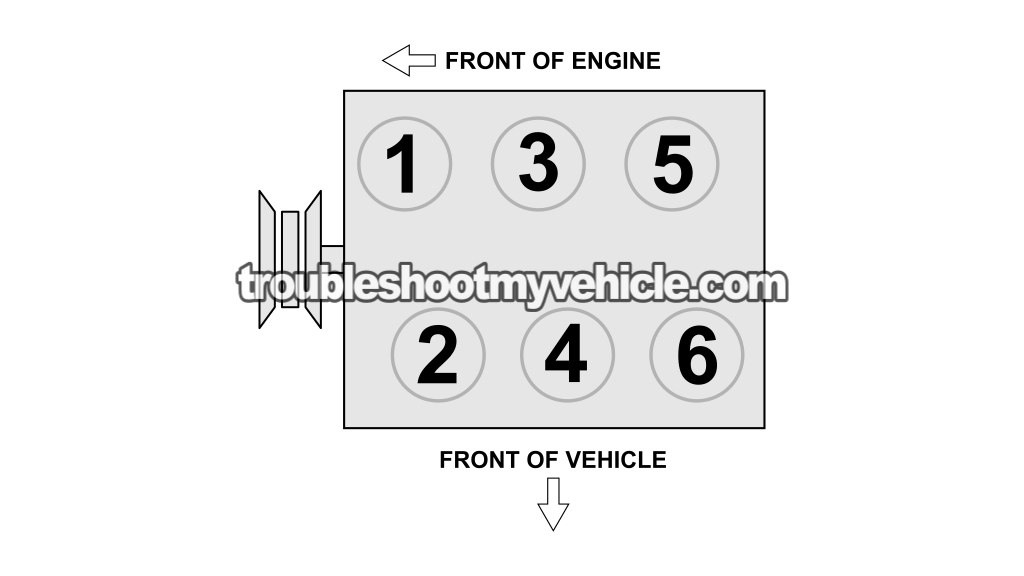

Even though three of those injectors sit underneath the intake manifold plenum (cylinders 1, 3, and 5), they can still be tested without removing the plenum.

In this tutorial, I'm going to explain how to check them right from the PCM's connector with a multimeter so you can quickly and easily find out if a bad fuel injector is causing a cylinder misfire on your 1993-1995 3.0L V6 Nissan Quest or Mercury Villager.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Nissan Quest: 1993, 1994, 1995.

- 3.0L V6 Mercury Villager: 1993, 1994, 1995.

FUEL INJECTOR CIRCUIT DIAGRAMS:

1996-1998 FUEL INJECTOR TESTS:

Symptoms Of A Defective Fuel Injector

For all six cylinders in your Nissan Quest or Mercury Villager's 3.0L V6 engine to be happy, they've got to have three things: fuel, spark, and compression. When one of these is missing from the mix (fuel, spark, or compression) in any one cylinder, that cylinder is going to misfire.

Besides a cylinder misfire, you may also see:

- Rough idle.

- Lack of power when you accelerate your Quest or Villager down the road.

An injector can fail to inject fuel due to one of the following failures:

- The internal coil winding (of the fuel injector) suffers a short-circuit or an open-circuit. When this happens, the fuel injector will stop injecting fuel completely.

- The fuel injector becomes clogged and does not atomize the fuel correctly or doesn't inject enough fuel.

- The fuel injector does not activate because it's not getting either power or activation signal from the fuel injection computer.

- The fuel injector comes on and stays on due to a short in the wiring for a defective fuel injection computer.

In this tutorial, I'm going to focus on testing the internal winding of all six injectors to see if any of them have suffered an internal electrical problem. But I'm also going to lay out a diagnostic strategy you can use to figure out if an injector is simply clogged —assuming your test results show that it hasn't suffered an internal electrical failure.

Testing The Fuel Injector Resistance

As I mentioned at the beginning of the tutorial, the fuel injectors for cylinders 1, 3, and 5 are underneath the intake manifold. The injectors for cylinders 2, 4, and 6 are easily accessible.

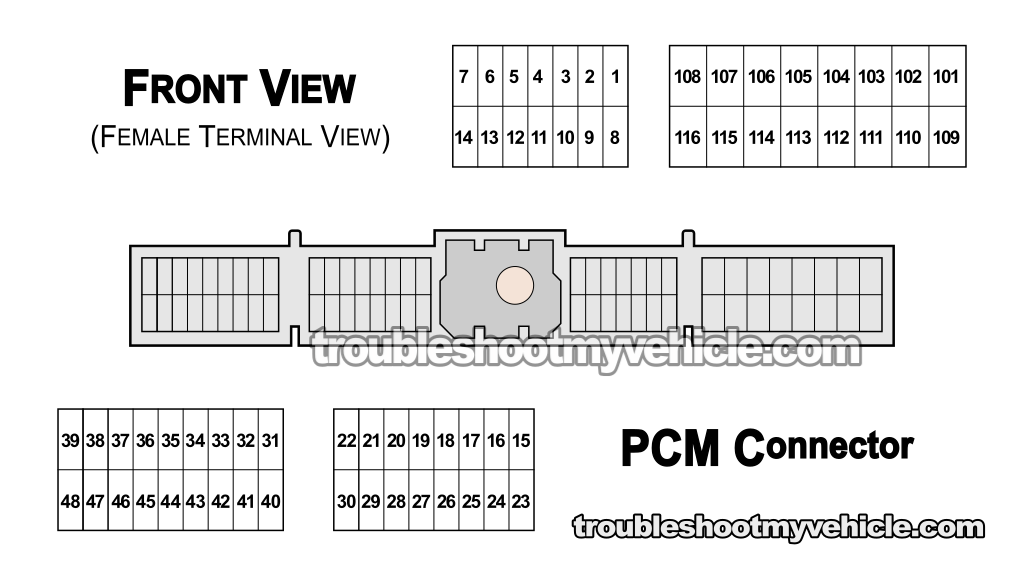

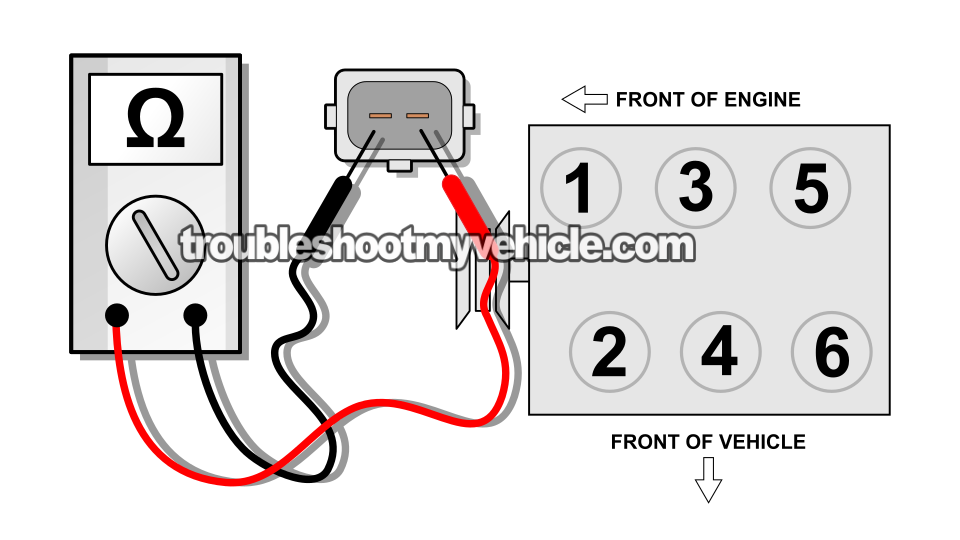

To check all of them in one go (without removing the intake manifold plenum), we're going to check their resistance right from your Nissan Quest's PCM's 116-pin connector.

Our multimeter resistance test will show one of two things:

- Good fuel injector: The injector resistance (and its circuit) will be between 10 and 14 Ohms.

- Bad fuel injector: Your multimeter will show infinite resistance (open-circuit) or zero Ohms (short-circuit).

Checking the resistance of the fuel injector circuits from the PCM connector is fairly easy, but there are some important precautions you've got to take. Since the PCM connector is not a weather-sealed connector, the standard procedure is to back-probe the terminal —in other words, you're going to probe the back of the connector where the wire exits.

You can probe the front of the female terminal, but you'll need to use multimeter probes with a very thin metallic tip to safely make contact without damaging the terminal. If you do plan on probing the front of the PCM female terminal, be sure to take a look at this guide I've written on how to safely probe the PCM connector on your Nissan Quest or Mercury Villager: How To Safely Probe The PCM Connector -Without Damaging It (1993-1998 3.0L V6 Nissan Quest).

PCM LOCATION: On your 1993-1995 Nissan Quest or Mercury Villager, the PCM (powertrain control module/fuel injection computer) is located underneath the front passenger seat.

NOTE: If you don't have a multimeter or you need to upgrade the one you've got, this is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

OK, let's get going:

- 1

Disconnect the battery's negative cable and leave it disconnected for the entire test.

NOTE: This step is important. Don't move on to the next step without first disconnecting the negative battery cable from the battery. - 2

Disconnect the PCM from its 116-pin connector.

- 3

Set your multimeter to Ohms mode.

- 4

With your multimeter test leads —and the appropriate tool— back probe between the following terminals of the 116-pin PCM connector:

—BANK 1 UNDER INTAKE MANIFOLD PLENUM:

- Injector 1: Pins 101 (GRN/ORG) and 46 (YEL).

- Injector 3: Pins 103 (GRN/RED) and 46 (YEL).

- Injector 5: Pins 105 (YEL/GRN) and 46 (YEL).

—BANK 2:

- Injector 2: Pins 110 (GRN) and 46 (YEL).

- Injector 4: Pins 112 (YEL/PPL) and 46 (YEL).

- Injector 6: Pins 114 (GRY/BLU) and 46 (YEL).

NOTE: Use the connector pinout above to locate VPWR (pin 46) and the injector pins.

- 5

Write the resistance value down on a piece of paper, and make sure you note which injector that value belongs to.

- 6

Your multimeter should report a resistance between 10 and 14 Ohms for each injector circuit.

If the meter shows an open-circuit, a short-circuit, or a resistance outside the 10-14 Ohm range, that injector circuit is bad.

Let's analyze your multimeter test results:

CASE 1: All fuel injector circuit resistances are within the indicated specification. This test result lets you know that the fuel injectors don't have an internal open-circuit or short-circuit problem. It also confirms that the wiring between each fuel injector connector and the PCM connector is OK.

If you're troubleshooting a rough idle or a cylinder misfire, then there's a good chance that one of those injectors is clogged —even though it passed the resistance test with flying colors. To continue troubleshooting the issue, head over to: How To Find The Bad Or Clogged Fuel Injector.

CASE 2: One or more fuel injectors showed infinite Ohms or zero Ohms. This test result confirms that you do have a fuel injector issue on your Nissan Quest or Mercury Villager.

At this point, the test doesn't tell us whether the problem lies in the injector itself or in the wiring between the injector connector and the PCM. We need to continue troubleshooting to find out which one it is. Head over to: Checking The Injector's Resistance Directly At Its Terminals

Checking The Injector's Resistance Directly At Its Terminals

If you've reached this section, one or more fuel injector circuits didn't pass the resistance test in the previous section and your multimeter reported one of the following readings:

- Infinite Ohms, which tells us the fuel injector circuit has an open-circuit problem.

- 0 Ohms, which indicates that the fuel injector circuit has a short-circuit problem.

- The resistance isn't within specification, but it's not a straight open or short-circuit issue. It's just out of range.

These failed resistance readings could be caused by the fuel injector itself or by its connector. Specifically, when we're talking about the injector connector, it's usually an issue with its two wires. To further troubleshoot this, we need to:

- Inspect the condition of fuel injector's connector and the 2 wires coming out of it.

- It's not uncommon for the wire insulation to crack and peel off right at the point where the wires exit the injector connector. Once that insulation falls away, the copper strands get exposed —and they end up shorting together.

- Check the resistance directly at the injector's two terminals.

- The fuel injector itself may have suffered an internal electrical issue —honestly, it's usually the most likely cause of the failed fuel injector circuit test (of the previous section).

- When checking the resistance of the injector directly at its terminals, you should see a reading between 10 and 14 Ohms.

The only thing that complicates things a bit here is if the failed fuel injector circuit belongs to cylinders 1, 3, or 5, since the injectors for these cylinders are located underneath the intake manifold plenum.

If it turns out that there's an issue with one of the injectors located underneath the plenum, you'll need to remove the plenum to check the injector's resistance right at its terminals and to inspect the condition of its connector. Before you begin, make sure to take a look at this section: The Intake Manifold Plenum Has To Be Removed.

If the failed circuits belong to cylinders 2, 4, or 6, you don't have to worry about removing the plenum, since those injectors are very accessible.

The Intake Manifold Plenum Has To Be Removed

Removing the intake manifold plenum is a bit of a process, but it's doable. I've done this a few times on these Nissan Quest and Mercury Villager minivans and can confirm it's not that complicated. I do want to point out a few important precautions/suggestions you've got to take to avoid any complications or headaches.

- Once you've removed intake manifold plenum, place clean shop towels over the exposed lower intake manifold ports. You want to make sure that nothing (like a bolt or a washer or any other metal component) falls into them as you're performing the fuel injector resistance tests.

- As you're removing bolts (or nuts), place them in a container that's located away from the engine compartment.

- Use new gaskets and install them dry. In other words, don't use any type of sealant on the gaskets when reinstalling the intake manifold plenum.

- If you do find a bad fuel injector connector, solder the new connector onto the engine wiring harness. Don't use crimp-style butt connectors. These won't hold up to road and engine vibration, and you'll be right back where you started —with a cylinder misfire. Soldering the new connector is the permanent solution.

One last thing, and I really want to emphasize this: don't let anything fall into the open lower intake manifold runners. If something falls in and you crank the engine, whatever nut or bolt ended up in that cylinder is going to cause a world of hurt. The piston and valves will get damaged fast, and the only way you'll be able to remove what fell in —and see what damage it caused— is by pulling one or both cylinder heads.

How To Find The Bad Or Clogged Fuel Injector

At first glance, it seems like troubleshooting a bad or clogged fuel injector is a pretty difficult thing to do on the Nissan Quest or Mercury Villager's 3.0L V6 engine —especially since three of those injectors are living underneath the intake manifold plenum. Not only that, but there are a bunch of other things that can go wrong and cause a cylinder to misfire or create a rough idle condition.

The good news is that if you've got a diagnostic strategy —and by this I mean a series of diagnostic tests— you can pinpoint the exact cause of the issue without having to throw parts at the engine to see what sticks.

In this section, I'm going to share the diagnostic strategy I've used my entire automotive repair career to easily and quickly find the exact source of a cylinder misfire, whether it's a bad/clogged fuel injector or something else. So if you don't know where to start, you've come to the right place.

OK, this is the step-by-step of what I do.

- Identify the dead cylinder:

- Since the 1993–1995 Nissan Quest/Mercury Villager isn't equipped with OBD2 diagnostics, you're not going to see specific cylinder-misfire trouble codes pinpointing the dead cylinder. Instead, you'll need to do a manual cylinder balance test.

- If you've never done one, I've written a tutorial that will walk you through the process, and you can find it here.

- Make sure that the dead cylinder is getting spark:

- This involves using a spark tester to check that the dead cylinder's spark plug wires is delivering spark to its spark plug.

- You'll also need to check the condition of the spark plug wire along its entire length to make sure it's not damaged in any way, shape, or form.

- Remove the dead cylinder's spark plug and inspect it closely. Make sure its air gap isn't blocked with carbon deposits, that its porcelain insulator isn't cracked, and there are no signs of carbon tracks (on its porcelain insulator). In other words, the spark plug should be in as close to perfect condition as possible.

- It's super important that you also check the inside of the spark plug wire boot for carbon tracks. If carbon tracks are present, the spark won't be channeled through the spark plug —it'll jump from the carbon track to the side of the engine instead.

- Carbon tracks are a pretty common issue, and you can read more about them in this real-life case study: Carbon Tracks Are A Common Cause Of Ignition Misfires (at: easyautodiagnostics.com).

- Check that the dead cylinder has good compression:

- This is a critical step we can't skip, since we've got to confirm that the dead cylinder can actually compress its air-fuel mixture —because if it can't, it's going to misfire.

- I've written a tutorial that explains how to perform and how to interpret a compression test on the Nissan Quest and Mercury Villager, and you can find it here: How To Do And Interpret An Engine Compression Test (1993-1998 3.0L V6 Nissan Quest).

- Check the internal resistance of the dead cylinder's fuel injector:

- Once I've eliminated all of the other usual suspects —which are lack of spark and lack of compression— then I check the fuel injector's internal resistance.

- If the resistance isn't within specification, then I've found the source of the cylinder misfire issue I'm troubleshooting.

- If the fuel injector's resistance is within specification, and I've confirmed that the dead cylinder doesn't have an ignition system issue —in other words, it's getting spark— and that the cylinder has good compression, then even though the injector's resistance checks out, I know it's clogged. At that point, I follow through and replace it.

At the heart of the diagnostic strategy I've outlined above is a simple process of elimination. The first step —and the most important one— is to ID the dead cylinder. From there, the rest of the process becomes easier, since all you have to do is figure out what that cylinder is missing. Is it missing spark? Is it missing compression? Is it missing fuel?

For me, the biggest benefit of checking these things (spark, compression, fuel) is that I avoid the frustration and the expense of replacing parts that just don't solve the issue.

More 3.0L V6 Nissan Quest Diagnostic Tutorials

You can find a complete list of 3.0L V6 Nissan Quest and Mercury Villager tutorials in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Ignition Coil And Power Transistor (1993-1998 3.0L V6 Nissan Quest).

- How To Test The Camshaft Position Sensor (1993-1998 3.0L V6 Nissan Quest).

- How To Test For A Blown Head Gasket (1993-1998 3.0L V6 Nissan Quest).

- Common Causes Of Spark Plug Failure (1993-1998 3.0L V6 Nissan Quest).

If this info saved the day, buy me a beer!